Metrohm NIRS XDS Process Analyzer – SingleFiber User Manual

Page 66

64

▪▪▪▪▪▪▪

Wavelength Linearization uses internal wavelength materials to determine a set of internal, arbitrary

peak positions that the instrument will use to maintain repeatability of wavelength response.

Wavelength Linearization is performed on the internal reference fiber located in the XDS Process

enclosure.

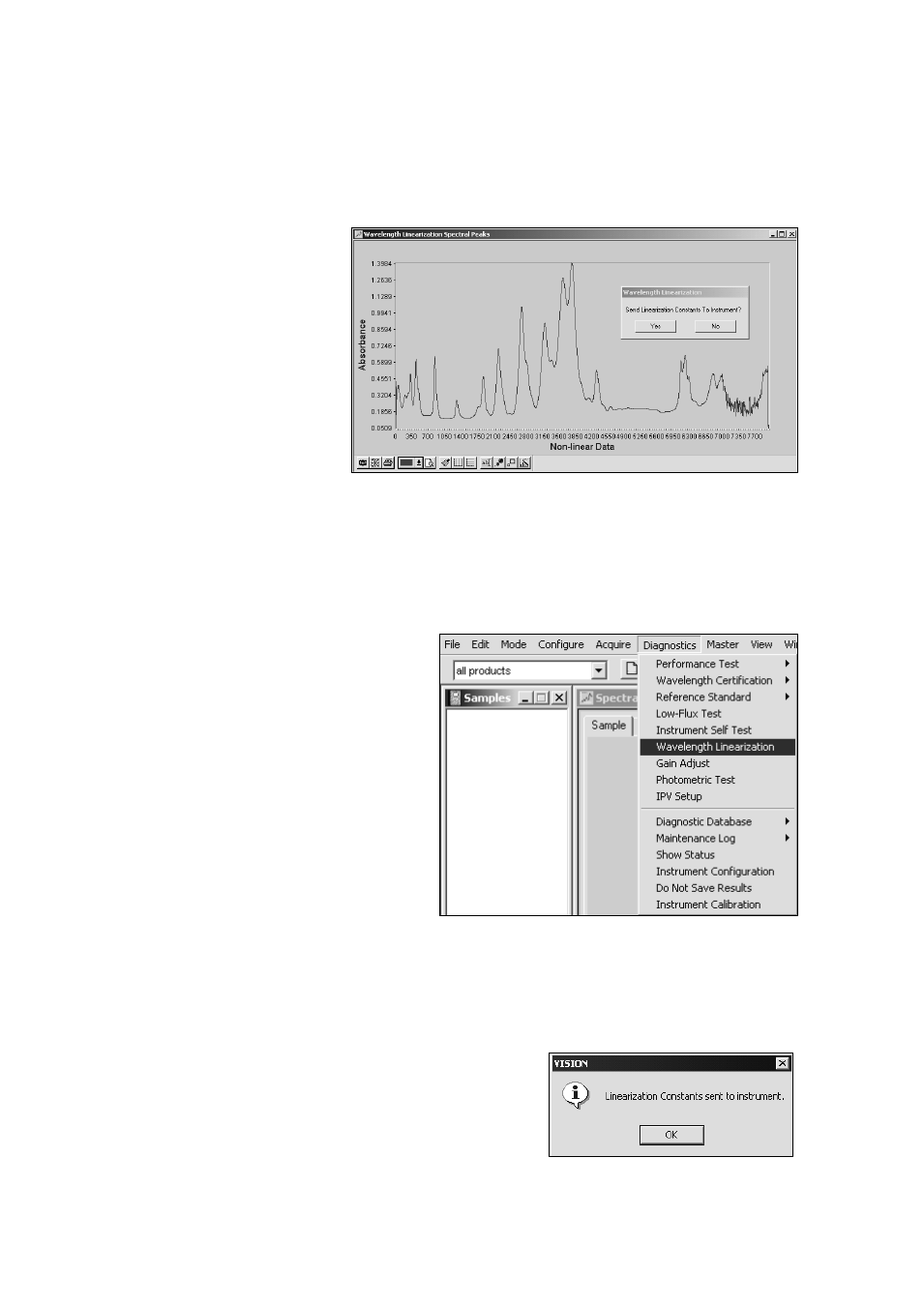

The NIR wavelength positions of

these peaks appear as shown.

The scale of this display is marked

in encoder pulses, which do not

relate to nanometers directly.

From the peaks, a linearization is

performed, which allows

assignment of nanometer values.

(Actual spectral shape depends on

fiber configuration.)

The spectrum shown above does not exhibit any noise effect from fiber attenuation. Actual fiber

optic probe spectra will exhibit noise at the lower and upper ends of the spectrum, based upon

length of fiber used. This is normal.

A Wavelength Linearization is performed in the forward direction of grating scan, then again in the

return direction. The resulting information is adjusted by Vision into one corrected spectrum.

These peak positions are not meant to be

traceable, as the wavelength calibration of the

instrument is done on an external standard,

traceable to NIST.

The internal wavelength materials are used to

maintain the external wavelength registration

by use of software adjustment for any

external effects on the instrument.

Select Wavelength Linearization from the

Diagnostics menu. The instrument will scan

the reference, which is the fiber optic that

runs from the monochromator to the detector

area inside the instrument.

Wavelength peak positions for the reference materials are located using a peak-finding algorithm.

These “found” peaks are compared to the wavelength nominals. This is done twice, one for each

direction of the grating motion. No operator interaction is required.

After the linearization is successfully sent to the instrument,

this message confirms the transfer.

Click “OK” to proceed.