Backward scheduling – Rockwell Automation FactoryTalk Scheduler Users Guide User Manual

Page 98

F

ACTORY

T

ALK

S

CHEDULER

U

SER

’

S

G

UIDE

92

• •

•

•

•

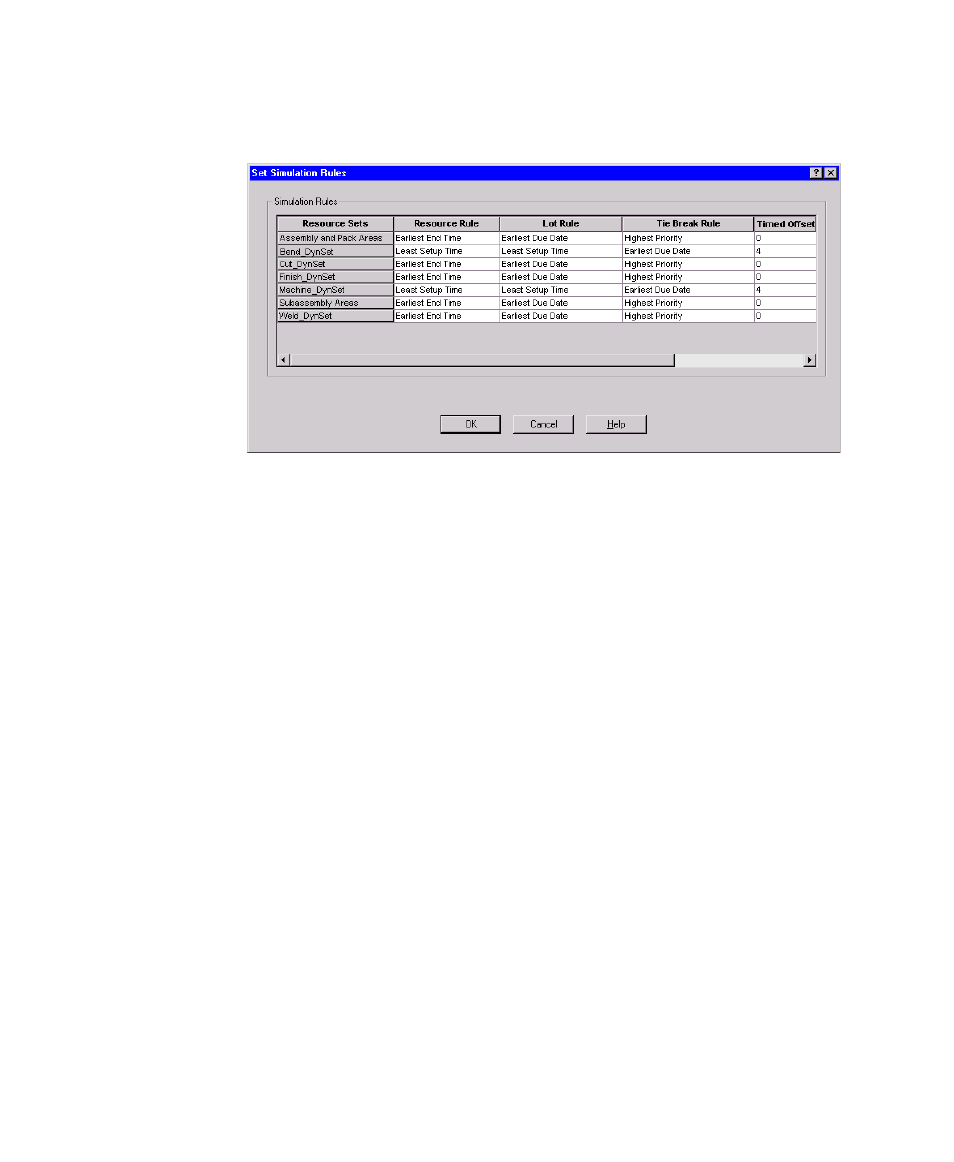

Now if we develop a schedule using simulation, it will use these new rules. This results in

a schedule with 11 late jobs—two more than for the default rules.

If you want to make the selection permanent, you can exit FactoryTalk Scheduler and edit

the FDM Data.

Now let’s retain the same base case and try other forms of scheduling as part of our

analysis.

Backward scheduling

Another form of scheduling that will occasionally provide good results is backward

scheduling. Using this type of methodology, we select an order and first schedule the last

operation to end on its due date, or as close as possible. We then work our way backward

through the order routing scheduling each operation as we proceed. This guarantees that

any order that can be scheduled completely will not be late, and it will tend to minimize

the work-in-progress. The idea is to generate a schedule that completes orders, as close to

on time as possible, without having any late orders. The problem that often develops using

this method is that it is not possible to schedule all orders in this manner because you

would have had to start, and possibly complete, some operations for orders before the

current time.

First, clear the planning board using the Sequence > Unallocate All Orders menu option.

Now select the Sequence > Backward > By Due Date menu option. The baseline

comparison indicates that we have 25 orders completed on time, 12 more than for the base

case, but eight of the orders are incomplete or unscheduled. This implies that these orders

can’t be scheduled with the backward method because there is insufficient time to

complete these orders. However, we can schedule these orders using the forward method.