The factory overview, The bizbikes manufacturing system, Bill of materials – Rockwell Automation FactoryTalk Scheduler Users Guide User Manual

Page 17: The manufacturing resource planning system

11

3

The Factory Overview

The BizBikes manufacturing system

To begin our assessment of the BizBikes factory, we’ll first examine their manufacturing

system and learn about the factory resources and processes. We will then use this model to

examine possible scenarios for improving our performance.

Bill of materials

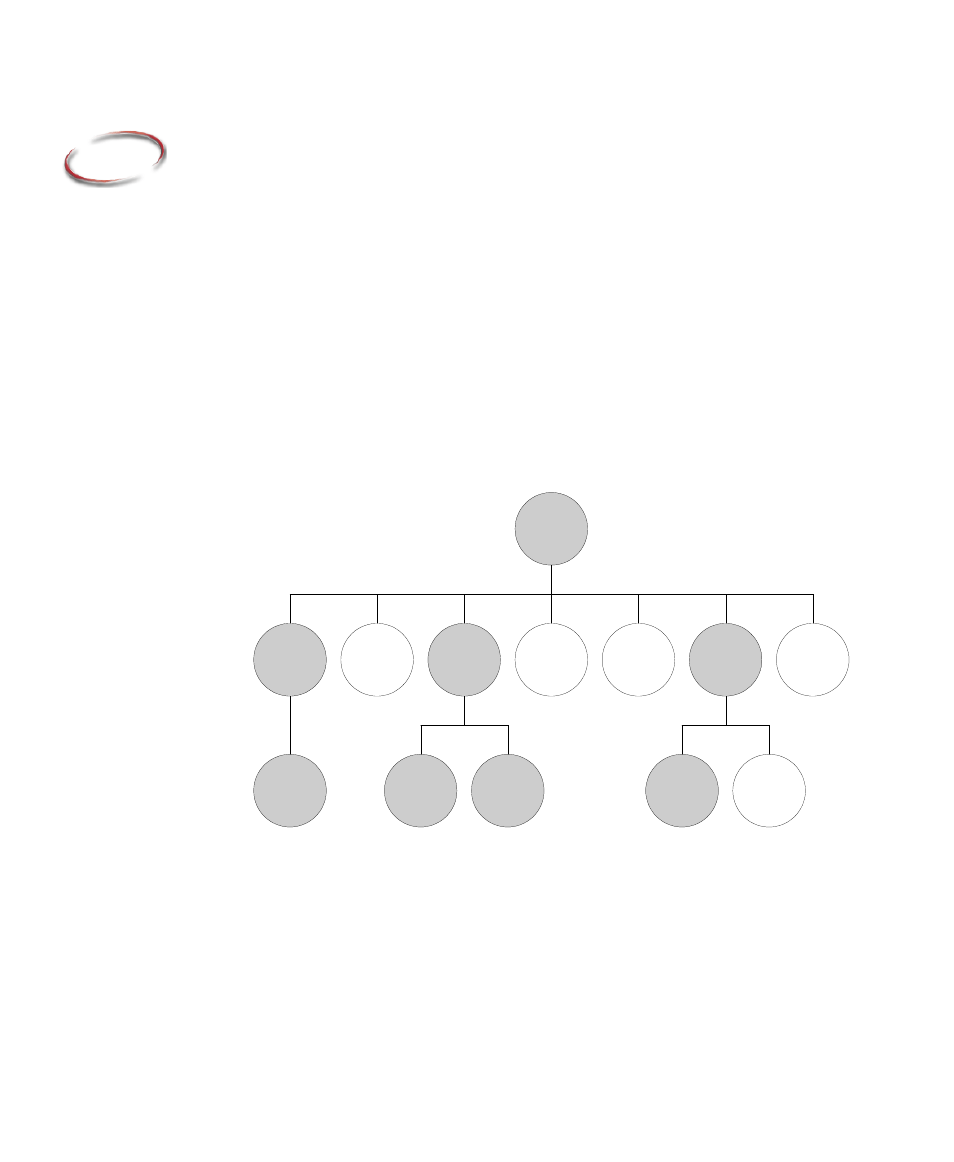

The bill of materials for BizBikes contains three levels, as shown below, for a generic end

item. There are actually four end items (or BizBikes), 15 unique manufactured items, and

five purchased parts. The shaded items in the bill of materials represent manufactured

components. This generic bill of materials also includes information on manufacturing

lead times, number required per subassembly, and lot size information.

The Manufacturing Resource Planning system

BizBikes employs a Manufacturing Resource Planning (MRP) system that performs

master planning and scheduling of weekly production. The MRP system consolidates

orders from multiple customers and plans the purchase and manufacturing of the

associated components. The MRP produces a set of manufacturing orders that are

released to the factory floor. These manufacturing orders are for both component parts

FINAL

ASSEMBLY

AND PACK

(1,1,1)

PEDAL AND

CHAIN

ASSEMBLY

(3,1,60)

HANDLEBAR

(3,1,100)

FINISHED

FRAME

(1,1,24)

NECK POST

(3,1,60)

WHEELS

(3,1,48)

FRAME

(4,1,50)

HANDLEBAR

ASSEMBLY

(1,1,75)

DERAILLEUR

ASSEMBLY

(4,1,60)

BRAKES

(2,1,75)

SEAT POST

(3,1,100)

SEAT

ASSEMBLY

(1,1,75)

SEAT

(2,1,100)

KEY: (Lead Time, Quantity, Lot Size)