Weld, Process plans, Final assembly and pack – Rockwell Automation FactoryTalk Scheduler Users Guide User Manual

Page 22

F

ACTORY

T

ALK

S

CHEDULER

U

SER

’

S

G

UIDE

16

• •

•

•

•

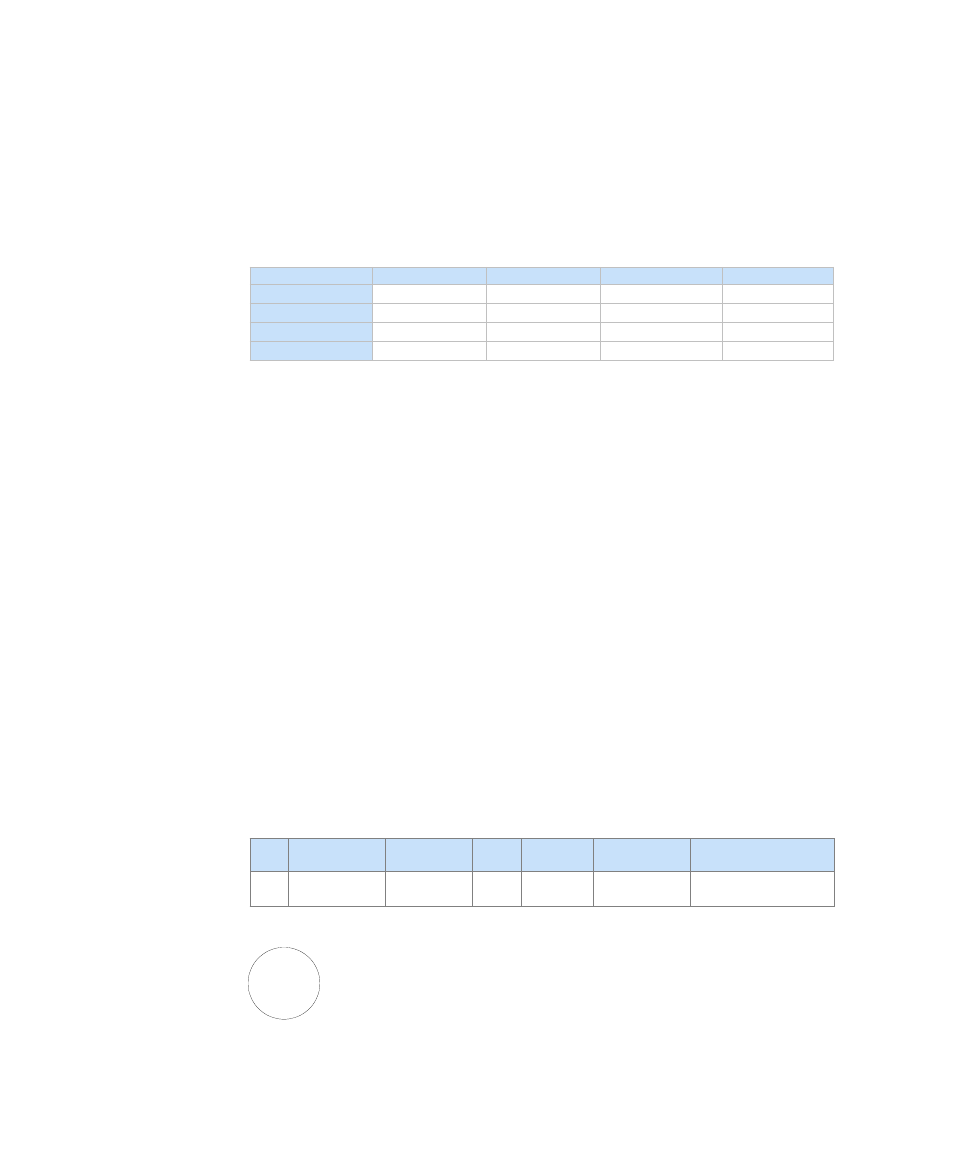

This matrix shows the setup time for an operation based on the previous production lot

that was processed at this work cell. For example, if the last production lot was

Handlebar, then the setup time to produce a Neck Post is .26 hours.

Bend Setup Matrix: BM

W

ELD

This work cell is also utilized for operations necessary to produce the component parts

required for the subassemblies. The process (per item) durations are part dependent. These

work cells are manned by a dedicated operation and do not require labor from the labor

pool. The setup duration for this work cell depends upon the frame type; i.e., we have a

different setup time for an SHP Frame and an SSD Frame. The setup time required to

change to an SHP Frame is 0.72 hours, and the time required to change to an SSD Frame

is 0.70 hours.

Process plans

There are eight different manufacturing order types, each with a different process plan or

routing.

F

INAL

A

SSEMBLY

AND

P

ACK

The process plans for assembly and packing of the SHP Red, SHP Blue, SSD Red, and

SSD Blue bicycles contain a single assembly operation. In this operation, a bicycle is

assembled from its components and subassemblies and then packaged for shipping. The

process plan for SHP Red Bicycle final assembly is summarized below.

SHP Red Bicycle Plan

SSD Frame

SHP Frame

Handlebar

Neck Post

SSD Frame

0.00 0.35 0.84 0.32

SHP Frame

0.42 0.00 0.84 0.32

Handlebar

0.93 0.97 0.00 0.28

Neck Post

0.75 0.78 0.39 0.00

Seq

#

Operation

Work Cell

Setup

Time

Process

Time

Additional

Resources

Notes

10 Assemble

and Pack

Assembly

and Pack

0.37

0.43

Labor (2)

Components required

10

ASSEMBLE

AND PACK