Handlebar assembly, Handlebar – Rockwell Automation FactoryTalk Scheduler Users Guide User Manual

Page 24

F

ACTORY

T

ALK

S

CHEDULER

U

SER

’

S

G

UIDE

18

• •

•

•

•

SHP Frame Plan

H

ANDLEBAR

A

SSEMBLY

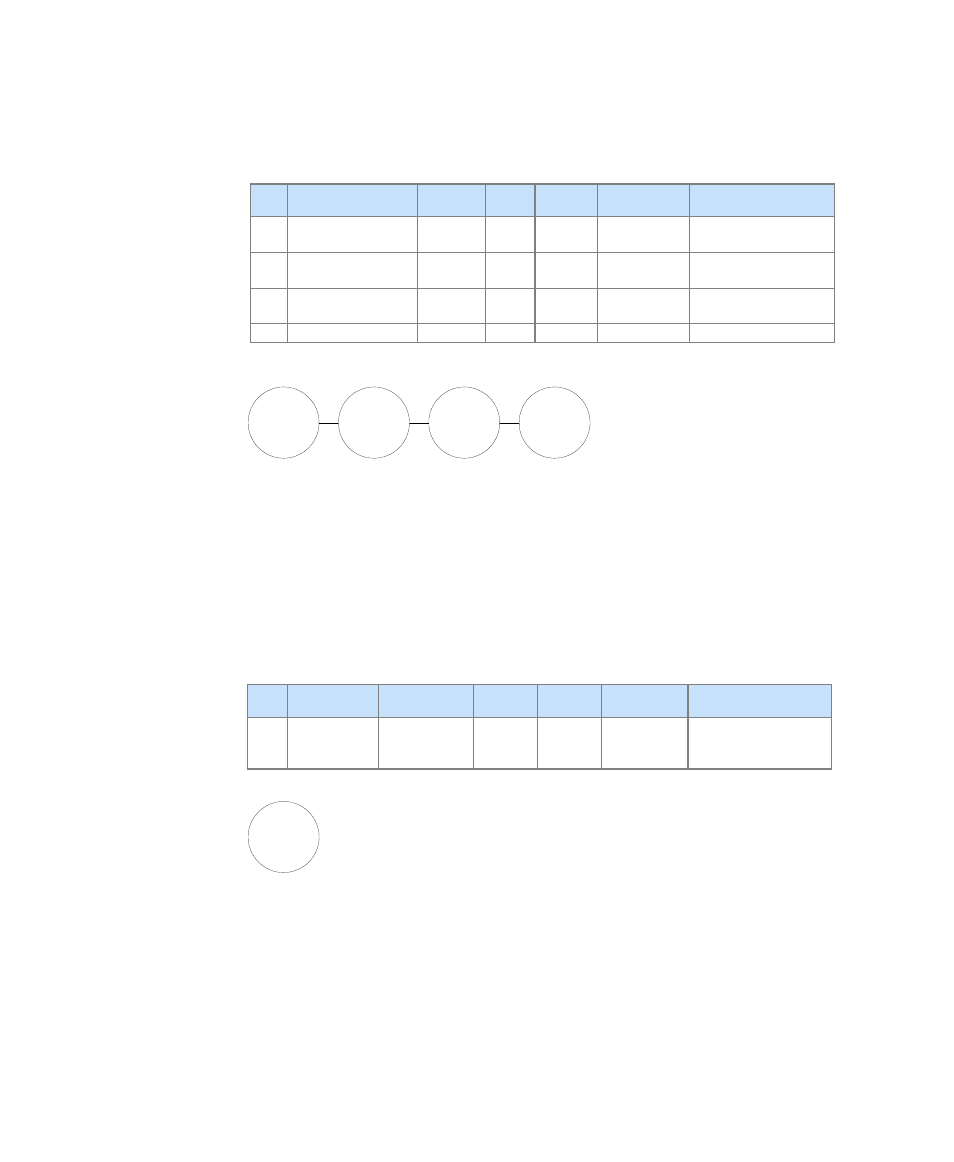

The process plans for the handlebar assembly contain a single subassembly operation. In

this operation, the previously manufactured handlebars and neck posts are assembled. The

subassembly is then placed in inventory where it is available for demand from a final

assembly order. The component parts required for this subassembly are a handlebar and

neck post for each subassembly to be produced. The process plan for Handlebar Assembly

is summarized below.

Handlebar Assembly Plan

H

ANDLEBAR

The process plans for a handlebar contain three operations: cut, bend, and finish. The

completed handle is then placed in inventory to be used by orders for handlebar

assemblies. The raw materials required at the cut operation have not been included in the

process plan as the material-planning replenishment process at the MRP level assures that

Seq

#

Operation

Work

Cell

Setup

Time

Process

Time

Additional

Resources

Notes

10 Cut SHP Frame

Tubing

Cut 0.36

0.120

20 Bend SHP Frame

Tubing

Bend BM

0.154

30 Machine

SHP

Frame Tubing

Machine MM 0.211

40

Weld SHP Frame

Weld

WD

0.234

Place in inventory

10

CUT FRAME

TUBING

20

BEND FRAME

TUBING

30

MACHINE

FRAME

TUBING

40

WELD

FRAME

Seq

#

Operation

Work Cell

Setup

Time

Process

Time

Additional

Resources

Notes

10 Assemble

Handlebar

Subassembly

0.21

0.072

Labor (1)

Handlebar and Neck

Post required;

Place in inventory

10

ASSEMBLE

HANDLEBAR