Introduction, Studio 5000 environment – Rockwell Automation 2094-xxxx Kinetix 6000 and Kinetix 6200/6500 Drive Systems Design Guide User Manual

Page 2

2

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Introduction

This publication assumes that your application uses the Kinetix® 6000, Kinetix 6200, or Kinetix 6500 drive family and that

you have already determined your motor/actuator series. To revisit those decisions, refer to the Kinetix Motion Control

Selection Guide, publication

, or Motion Analyzer software.

With Kinetix 6000 and Kinetix 6200 drive systems, Kinetix 6000M integrated drive-motor (IDM) systems are another

option. Cables between the IDM units and the IDM power interface module (IPIM) are unique to IDM systems.

Accessories shared with the Bulletin 2094 drive system include sercos fiber-optic cables and safe-off headers and cables.

The purpose of this publication is to assist you in identifying the drive system components and accessory items you’ll need

for your drive and motor/actuator combination or Kinetix 6000M integrated drive-motor system. Diagrams in this

publication illustrate how many of the common drive accessory items are used in a typical system, but refer to the Kinetix

Motion Accessories Technical Data, publication

, for detailed accessory descriptions and specifications.

Also provided are drive/motor or drive/actuator system combinations that include the following:

• Motor/cable combinations table

• Drive and motor/actuator performance specification table

• Torque/speed curves with each motor matched to the drive with optimum performance

Performance specification data and curves reflect nominal system performance of a typical system with motor/drive at

rated ambient temperature and line voltage. For additional information on ambients, line conditions, and valid

combinations not shown in this publication, refer to Motion Analyzer software.

Studio 5000 Environment

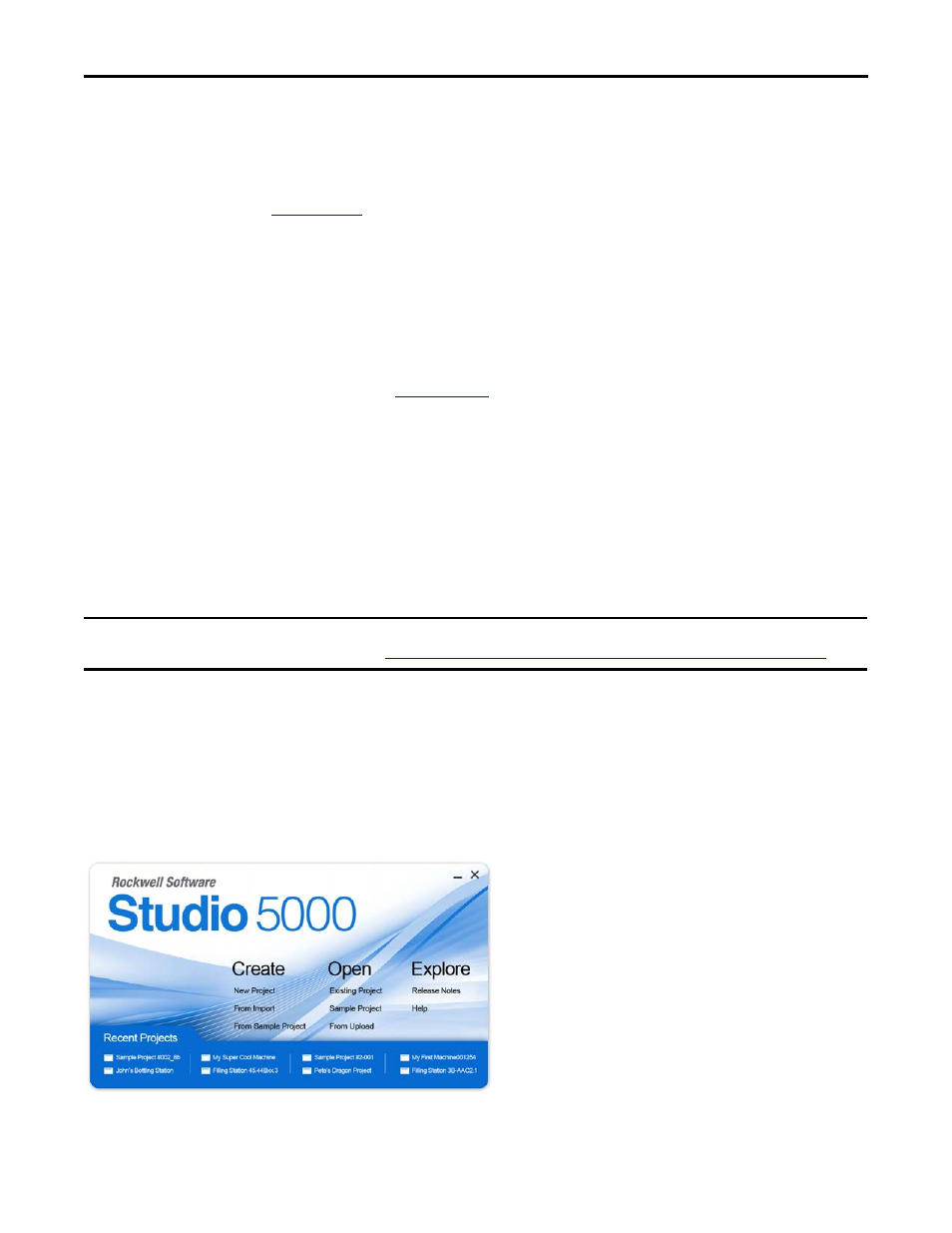

The Studio 5000™ Engineering and Design Environment combines engineering and design elements into a common

environment. The first element in the Studio 5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix™ 5000 software and will continue to be the product to program Logix5000™

controllers for discrete, process, batch, motion, safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell Automation® engineering design tools and

capabilities. It is the one place for design engineers to develop all the elements of their control system.

IMPORTANT

These system combinations do not include all possible motor/drive combinations. Please refer to Motion Analyzer software to

verify compatibility. Download fr