Fiber optic cabling – Rockwell Automation 7000A PowerFlex Medium Voltage AC Drive (A Frame) - ForGe Control User Manual

Page 93

Rockwell Automation Publication 7000A-UM200C-EN-P - June 2014

93

Component Definition and Maintenance

Chapter 3

Fiber Optic Cabling

The equipment is provided with fiber optic cabling as a means of interfacing the

low voltage control to the medium voltage circuits. The user of the equipment

should never need to change the routing of the fiber optic cables.

Each end of a fiber optic cable is provided with a connector that plugs and latches

into its respective location on a circuit board. To disconnect a fiber optic cable,

depress the ridged plastic tab at the end connector and pull. To install a fiber

optic cable insert the fiber optic port of the circuit board so that the plastic tab

latches into place.

If the user finds it necessary to replace fiber optic cables, great care must be taken

to prevent the cables from becoming strained or crimped as a resulting loss in

light transmission will result in loss in performance.

The minimum bend radius permitted for the fiber optic cables is 50 mm (2.0 in.).

When installing the fiber optic cable, the color of the connector at the end of the

cable must match the color of the connector socket on the circuit board.

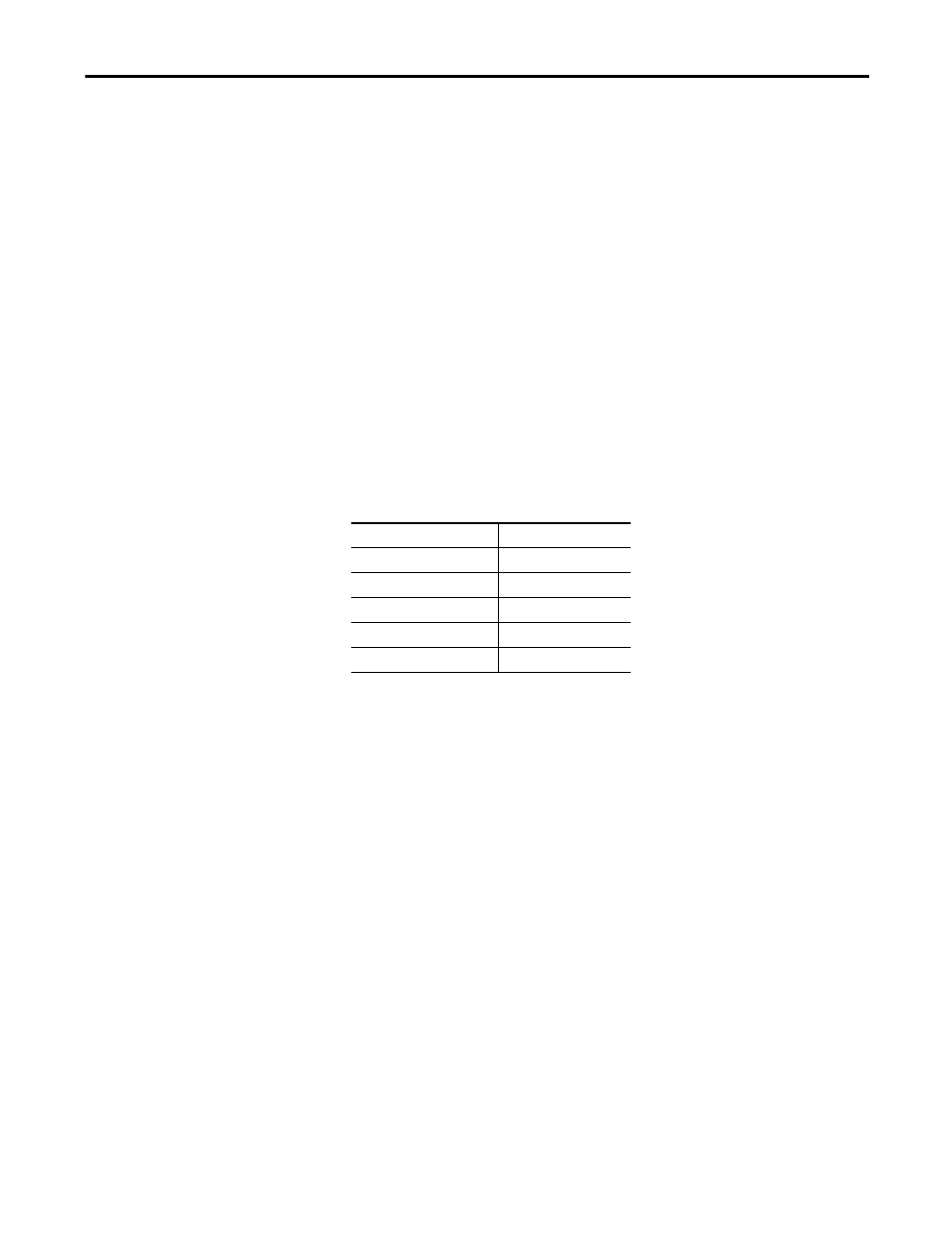

Lengths of fiber optic cables used in the product include:

There is one duplex fiber optic for each thyristor, which manages gating and

diagnostic functions. The healthy status of the thyristor is determined by the

circuitry on the respective driver boards. This information is then sent to the

main processor via a fail-safe light signal in the fiber optic. The firing command

for the thyristor is initiated by the main processor and transmitted to the

appropriate gate driver board via the gating fiber optic.

The color codes of the connectors are:

•

BLACK or GREY – is the transmitting end of the fiber optic.

•

BLUE – is the receiving end of the fiber optic.

Duplex

Simplex

5.0 m

5.0 m

5.5 m

6.0 m

6.0 m

10.0 m

6.5 m

7.0 m