Encoder signal – differential, dual channel, 1) shld connection is on drive chassis, 2) example applies to 20b-enc-1 only – Rockwell Automation 20D PowerFlex 700 Installation Instructions - Frames 7…10 User Manual

Page 55

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

55

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

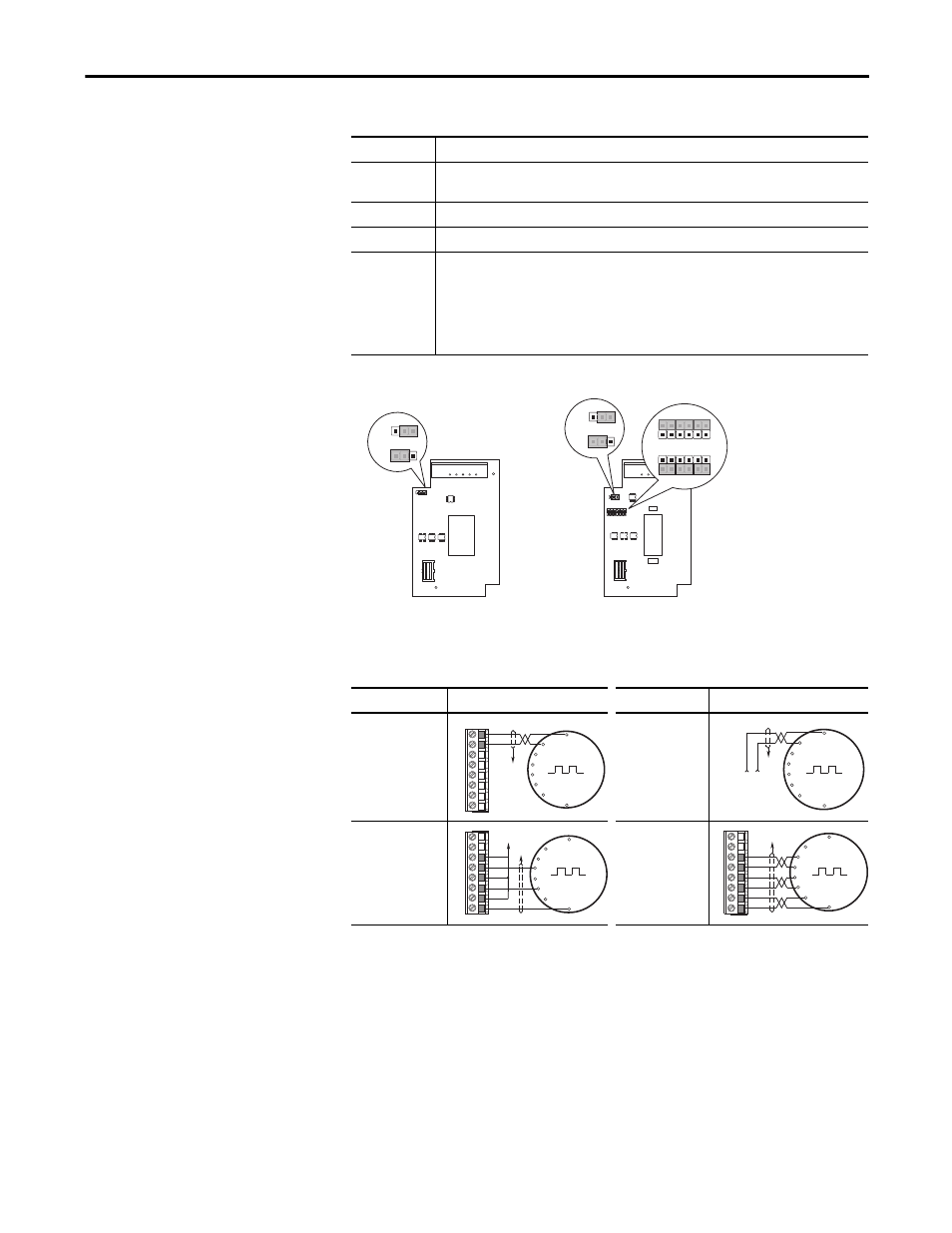

Encoder Specifications

+5/12V Encoder Jumper Location

Sample Encoder Wiring

Type:

Incremental, dual channel

Supply:

12V, 250 mA. 12V, 10 mA minimum inputs isolated with differential transmitter, 250 kHz

maximum.

Quadrature:

90°, ±27 degrees at 25 degrees C.

Duty Cycle:

50%, +10%

Requirements:

Encoders must be line driver type, quadrature (dual channel) or pulse (single channel), 8-15V DC

output (3.5-6V DC when jumpers are in 5V position), single-ended or differential and capable of

supplying a minimum of 10 mA per channel. Maximum input frequency is 250 kHz. The Encoder

Interface Board accepts 12V DC square-wave with a minimum high state voltage of 7.0V DC. With

the jumpers in the 5V position, the encoder accepts a 5V DC square-wave with a minimum high

state voltage of 3.1V DC. In either jumper position, the maximum low state voltage is 0.4V DC.

I/O

Connection Example

I/O

Connection Example

Encoder Power –

Internal Drive

Power

Internal (drive) 12V

DC, 250mA

(1)

(1) SHLD connection is on drive chassis.

Encoder Power –

External Power

Source

Encoder Signal –

Single-Ended,

Dual Channel

(2)

(2) Example applies to 20B-ENC-1 only.

Encoder Signal –

Differential,

Dual Channel

J3

5/12V

(20B-ENC-2)

J3

J2

+12V

1

2

3

12 11

21

+5VREF

5/12V

(20B-ENC-1, Series B)

J3

+12V

1

2

3

+5VREF

1

2

3

+5V

+12V

1

2

3

1

2

3

+5V

+12V

1

2

3

+12V

+5V

12 11

21

12 11

21

Output

Config.

J3

Output

Config.

J2

Intput

Config.

Common

+12V DC

(250 mA)

1

2

3

4

5

6

7

8

to SHLD

(1)

+

Co

mmon

External

Power

Supply

to

SHLD

(1)

B

B NOT

A NOT

A

Z

Z NOT

to SHLD

(1)

to Power Supply

Common

1

2

3

4

5

6

7

8

to SHLD

(1)

1

2

3

4

5

6

7

8

B

Z

A NOT

B NOT

Z NOT

A