141 performance data (cont) – Bryant DURAPAC 551B User Manual

Page 141

141

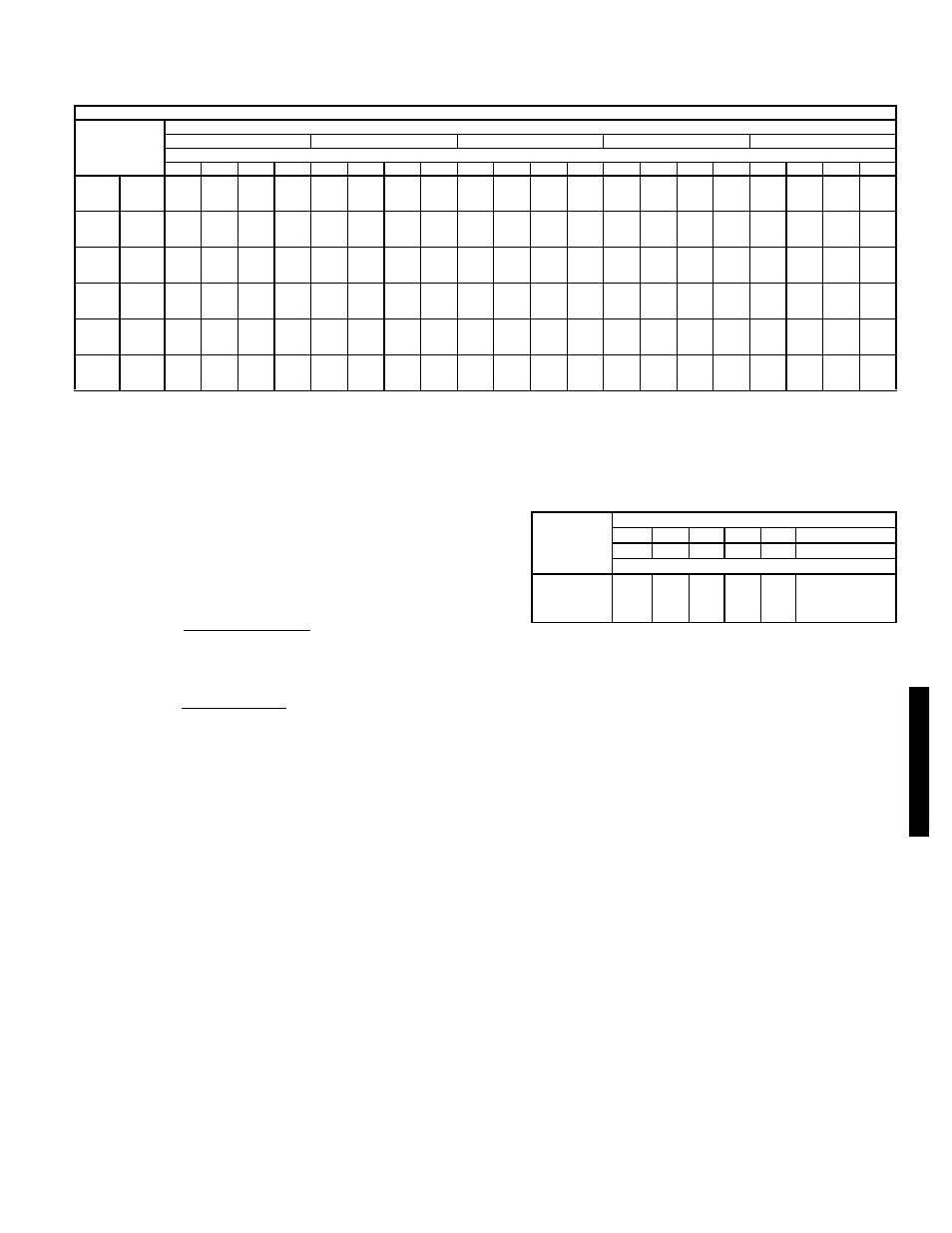

PERFORMANCE DATA (cont)

COOLING CAPACITIES (cont)

COOLING CAPACITIES LEGEND AND NOTES

LEGEND

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

Where: hewb = Enthalpy of air entering evaporator coil

3. The SHC is based on 80 F edb temperature of air entering evaporator coil.

Below 80 F edb, subtract (corr factor x cfm) from SHC.

Above 80 F edb, add (corr factor x cfm) to SHC.

Interpolation is permissible.

Correction Factor = 1.10 x (1 – BF) x (edb – 80).

558F300 (25 TONS)

Temp (F)

Air Entering

Condenser

(Edb)

Air Entering Evaporator — Cfm/BF

7,000/0.05

8,000/0.06

9,000/0.07

10,000/0.08

11,250/0.09

Air Entering Evaporator — Ewb (F)

57

62

67

72

57

62

67

72

57

62

67

72

57

62

67

72

57

62

67

72

75

TC

256

271

299

327

267

278

305

336

276

283

309

341

285

286

313

344

294

294

316

347

SHC

256

232

196

159

267

249

208

166

276

265

220

173

285

281

232

182

294

294

252

198

kW

18.0

18.3

18.9

19.6

18.3

18.5

19.1

19.8

18.5

18.7

19.2

19.9

18.7

18.8

19.4

20.1

19.0

19.0

19.5

20.2

85

TC

248

262

288

316

259

267

293

322

267

273

298

328

276

276

302

331

284

285

305

336

SHC

248

228

192

154

259

244

204

161

267

259

216

169

276

274

228

175

284

284

244

187

kW

20.0

20.4

20.9

21.5

20.3

20.4

21

21.7

20.6

20.6

21.2

21.9

20.8

20.8

21.3

22

21

21

21.5

22.1

95

TC

241

252

277

303

251

257

281

309

259

262

286

314

266

267

290

317

274

275

293

321

SHC

241

223

187

149

251

239

198

157

259

254

210

164

266

265

222

171

274

275

238

180

kW

22.4

22.6

23.1

23.7

22.6

22.7

23.3

23.9

22.8

22.9

23.4

24

23

23

23.5

24.2

23.2

23.2

23.6

24.2

105

TC

233

243

266

289

242

247

270

295

250

252

273

299

256

258

277

303

264

265

280

306

SHC

233

218

182

145

242

233

194

152

250

248

206

159

256

257

217

166

264

265

232

176

kW

24.9

25.1

25.6

26.2

25.2

25.3

25.8

26.3

25.4

25.4

25.9

26.5

25.6

25.6

26

26.6

25.8

25.8

26.1

26.7

115

TC

225

232

254

277

234

236

258

281

241

242

261

285

247

247

264

288

254

255

267

291

SHC

225

214

178

140

234

228

189

148

241

241

201

155

247

247

211

162

253

255

227

171

kW

27.9

27.9

28.5

29

28

28.1

28.6

29.2

28.2

28.2

28.7

29.2

28.4

28.4

28.8

29.3

28.7

28.7

28.9

29.5

125

TC

216

221

241

263

224

225

245

267

231

231

248

269

237

236

251

273

243

242

253

276

SHC

216

208

173

136

223

221

184

142

230

231

196

149

236

236

206

157

243

242

221

166

kW

30.9

31.1

31.6

32

31.2

31.2

31.7

32.2

31.4

31.4

31.7

32.3

31.6

31.6

31.9

32.3

31.7

31.7

31.9

32.5

BF

—

Bypass Factor

Edb

—

Entering Dry-Bulb

Ewb

—

Entering Wet-Bulb

kW

—

Compressor Motor Power Input

ldb

—

Leaving Dry-Bulb

lwb

—

Leaving Wet-Bulb

SHC

—

Sensible Heat Capacity (1000 Btuh) Gross

TC

—

Total Capacity (1000 Btuh) Gross

tldb = tedb

–

sensible capacity (Btuh)

1.10 x cfm

tlwb =

Wet-bulb temperature corresponding to enthalpy of air

leaving evaporator coil (h

lwb

)

hlwb = hewb –

total capacity (Btuh)

4.5 x cfm

BYPASS

FACTOR

(BF)

ENTERING AIR DRY-BULB TEMP (F)

79

78

77

76

75

under 75

81

82

83

84

85

over 85

Correction Factor

.05

1.04

2.07

3.11

4.14

5.18

Use formula

shown below.

.10

.98

1.96

2.94

3.92

4.90

.20

.87

1.74

2.62

3.49

4.36

.30

.76

1.53

2.29

3.05

3.82

0

T

F

Q

0

04

-0

12

55

8F1

80-

30

0