Assembly, Preparing the adapter – MacDon 873 Combine Adapter User Manual

Page 48

Form # 147069

Issue 09/06

46

ASSEMBLY

Preparing the Adapter

POSITION THE RETRACTING TINE DRUM (continued)

IMPORTANT: To prevent damage to header side

drapers or adapter drum when dimension “X” (from

previous page) exceeds 10” (255 mm) on 972, 973 &

974 headers, or 9-1/2” (235 mm) on 963 headers,

float lockout pins must be located to prevent header

from floating fully up when float is engaged.

NOTE: Adapter leg must also be in position “B” when

RTD is this far forward, refer to page 39.

To find a safe position for float lockout pins for these

situations:

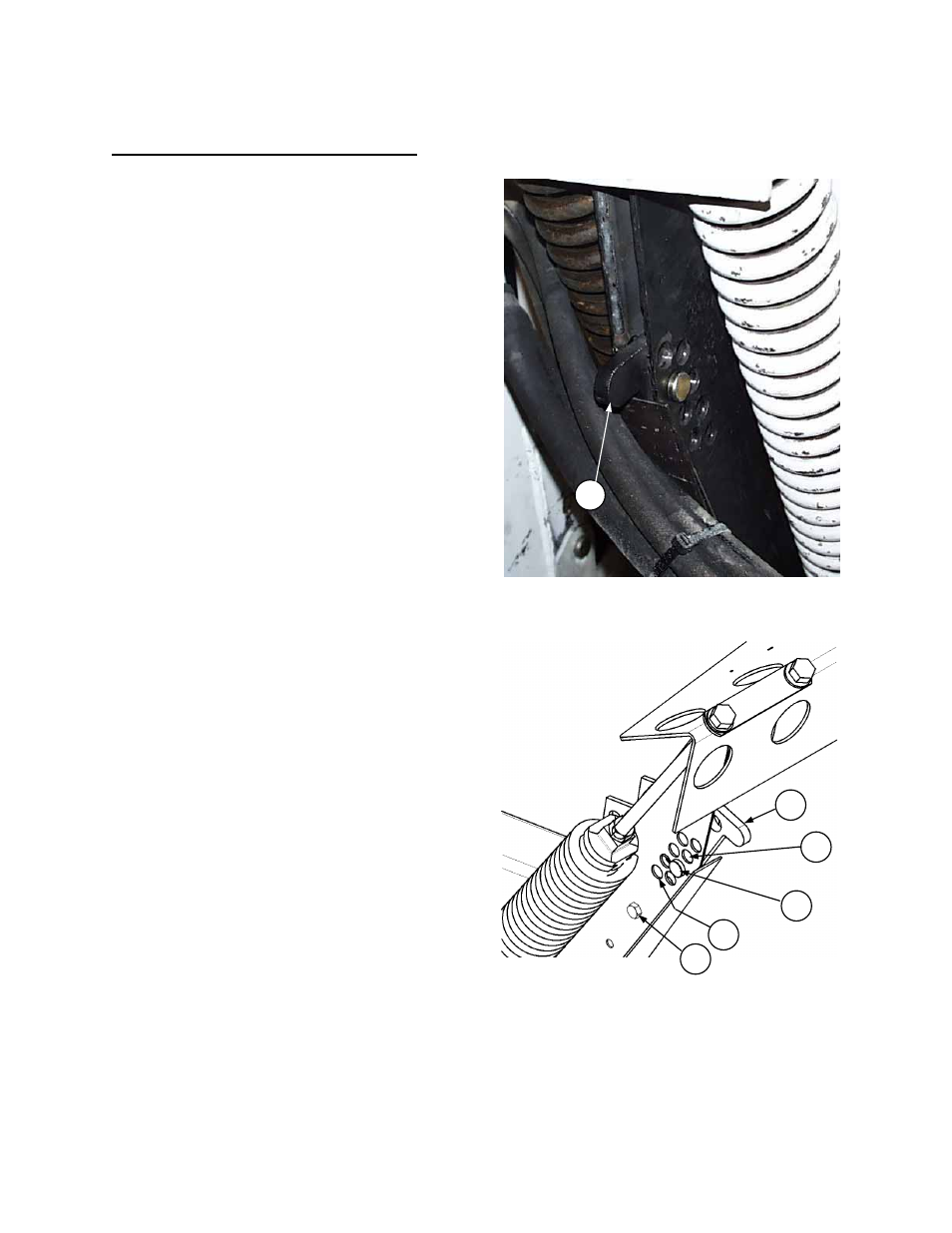

1. The normal “float engaged” position for handle (A)

is fully down as shown. In situations where float

must be limited to prevent damage, the handle

must be raised and pinned in a higher position.

2. To find this position, once header is attached,

shorten center link to minimum length and float

header up. For 974 Headers, set to maximum

“smile” position by lowering onto 5” (125 mm)

blocks at each end.

3. Raise handle (A) both sides, to hole (J) for

963/973/974 Headers or hole (K) for 972

Headers. This is the “header attach” position and

ensures no interference.

NOTE: For John Deere Contour Master combines

with 963 Harvest Headers, rest handle (A) on bolt

(B) and place pin in hole (L). Bolt (B) should be

located in lower hole for all other combines.

4. Starting from this position, lower handle one hole

at a time and turn drum by hand, checking for

interference.

5. When interference occurs, return to previous

higher position and make a mark on the float

frame at top of handle for future reference. Use

this position when operating the header.

A

LIMIT FLOAT BY RAISING “ENGAGED”

POSITION OF HANDLE

J

K

START FROM “HEADER ATTACH” POSITION

AND LOWER HANDLE TO FIND “FLOAT

LIMITED” OPERATING POSITION

L

A

B