Operation – MacDon 873 Combine Adapter User Manual

Page 21

Form # 147069

Issue 09/06

19

OPERATION

963/972/973 HEADER FLOTATION (continued)

When working with cutterbar on ground (e.g. soybeans):

• Set top link length to mid-range position, 19-1/4” (490 mm).

• Set float arm gap to 1/2” (13 mm) as described on previous page.

• Best float operation will occur with minimum extra weight on header. Consider removing gauge wheels or

transport attachments, if equipped.

• Adjust float optimizer (if equipped) or feeder house height while watching float indicator to set cutterbar

down force. Installation of the float optimizer attachment is recommended for cutting on the ground if the

combine is equipped as required.

• Adjust header angle to achieve desired stubble height.

• In rocky fields, adjust skid shoes down. This raises guards when operating at the flattest header angle to

minimize scooping rocks.

• If cutterbar begins to push dirt during operation, adjust header height (with optimizer or feeder house

height control) to minimize pushing.

• Header angle and reel fore-aft position can be changed without significantly effecting header flotation

(down force).

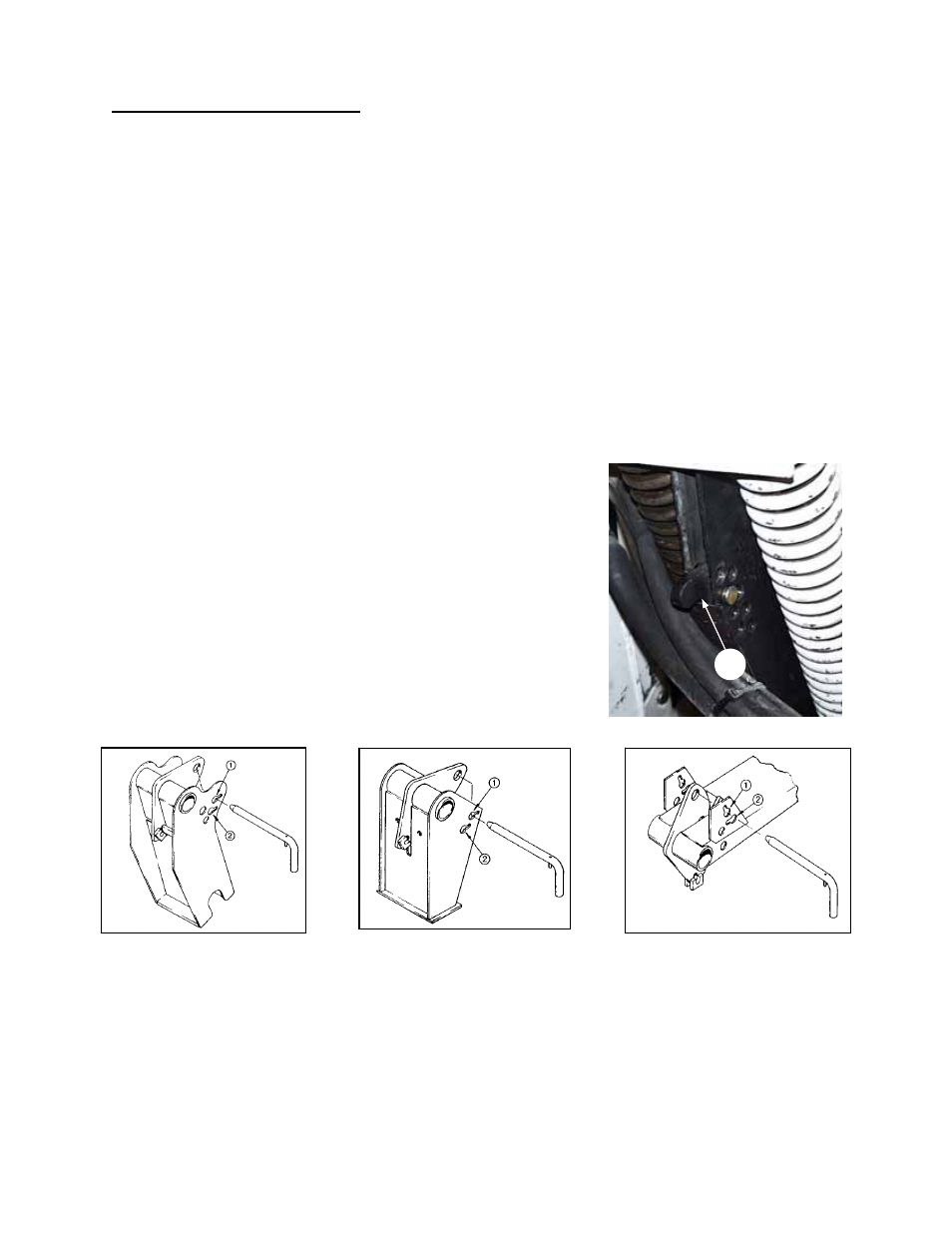

Header Floatation for 963 Headers with Gauge Wheel/Transport Wheel:

1. Set guard angle and reel to desired position for cutting conditions

and slide handle (A) down to engage float.

2. Choose gauge wheel position to maintain proper gauge wheel spring

force at desired cutting height.

Field Position 1: when cutter bar is above the ground 4 to 12 inches

(100 to 300 mm) cutting height)

Field Position 2: when cutterbar is close to the ground 2 to 5 inches (50

to 125 mm) cutting height)

Storage (locked out): when cutter bar is on the ground 0 to 2 inches (0

to 50mm) cutting height. Header is run on skid

shoes and height is controlled by guard angle.

TRANSPORT PKG

LEFT WHEEL SUPPORT

TRANSPORT PKG

RIGHT WHEEL SUPPORT

STANDARD GAUGE

WHEEL SUPPORT

ADAPTER FLOAT ENGAGED

A