Header attaching & detaching – MacDon 873 Combine Adapter User Manual

Page 14

Form # 147069

Issue 09/06

12

5/16”

(5mm – 10mm)

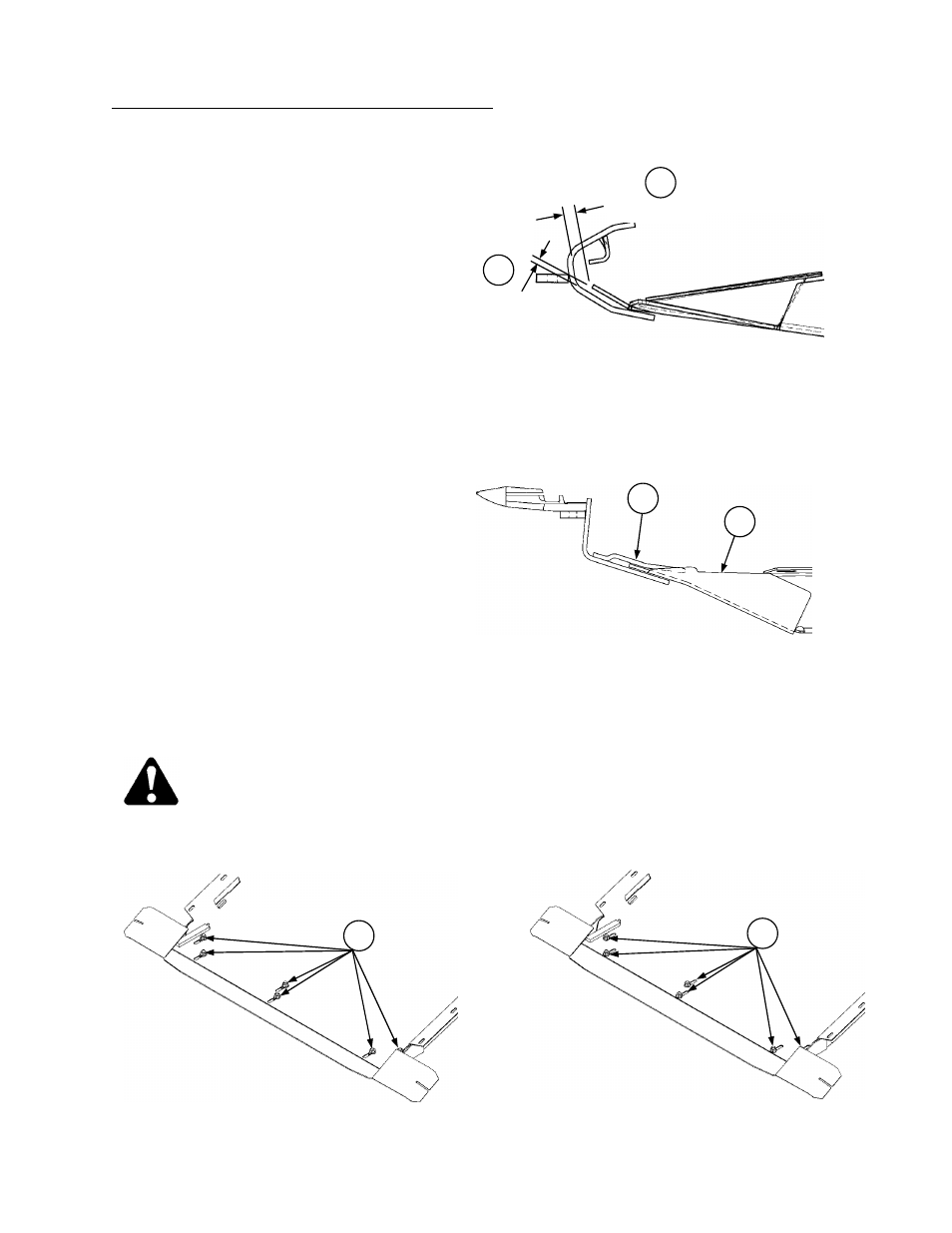

PAN CLEARANCE TO CUTTERBAR

972/973/974 HEADER

NOTE: A 5-10mm gap at (A) is equivalent to a

15-20mm gap at (B).

11/16”

(15mm – 20mm)

A

B

HEADER ATTACHING & DETACHING

ATTACHING HEADER TO COMBINE AND ADAPTER (continued)

NOTE: Steps 17 to 19 are for 972, 973 and 974 Headers. For 963 Header, go to Step 20.

17. Fore aft positioning of the feed pan is critical.

Pan must be far enough forward to securely

engage the cutterbar, but not so far forward to

cause jamming, which prevents proper

function of the float system and causes header

vibration. Adjust feed pan engagement as

follows:

• 972 & 973 Headers: Extend top link to

maximum length and raise header about 6” (150

mm) off ground. Ensure adapter is resting on

float down stops and adjust front of pan to

provide a 5/16” (5-10 mm) gap at cutterbar. See

NOTE at right.

• 974 Header: Extend top link to maximum length

and set header to maximum “smile” position by

lowering onto 5” (125 mm) blocks at each end.

Ensure adapter is resting on float down stops

and adjust front of pan to provide a 5/16” (5-

10mm) gap at cutterbar. See NOTE at right.

18. Return top link to mid-range operating length of

19-1/4” (490 mm).

19. Disengage lift cylinder stop and lower header to

ground.

NOTE: Steps 20 & 21 are for 963 Headers only:

20. Ensure transition plate (C) fully engages adapter

support anchors (D) on cutterbar.

NOTE: For all combines slide transition plate

fully rearward in feed pan slots when adapter leg

pin is located in hole A (page 39). Slide

transition plate fully forward in feed pan slots

when adapter leg pin is located in hole B (page 39).

(See illustrations below).

21. Adjust transition plate location as follows:

a. Raise the header. Stop engine and remove key. Ensure that adapter float arm is on the down stop.

DANGER: To avoid bodily injury from fall of raised header, engage header lift cylinder

stops when working on or around raised header. See your Combine Operator's Manual for

details.

b. Loosen six nuts (E).

c. Slide transition plate into position for your specific combine make and model (as shown below).

d. Tighten six nuts (E).

963/873 TRANSITION PLATE LOCATION

(When adapter leg pin in hole A – refer to page 39)

E

963/873 TRANSITION PLATE

(When adapter leg pin in hole B – refer to page 39)

E

C

D

963 TRANSITION PLATE ENGAGEMENT