Maintenance/service – MacDon 873 Combine Adapter User Manual

Page 32

Form # 147069

Issue 09/06

30

MAINTENANCE/SERVICE

HYDRAULIC SYSTEM (continued)

Flow Control Relief Pressure

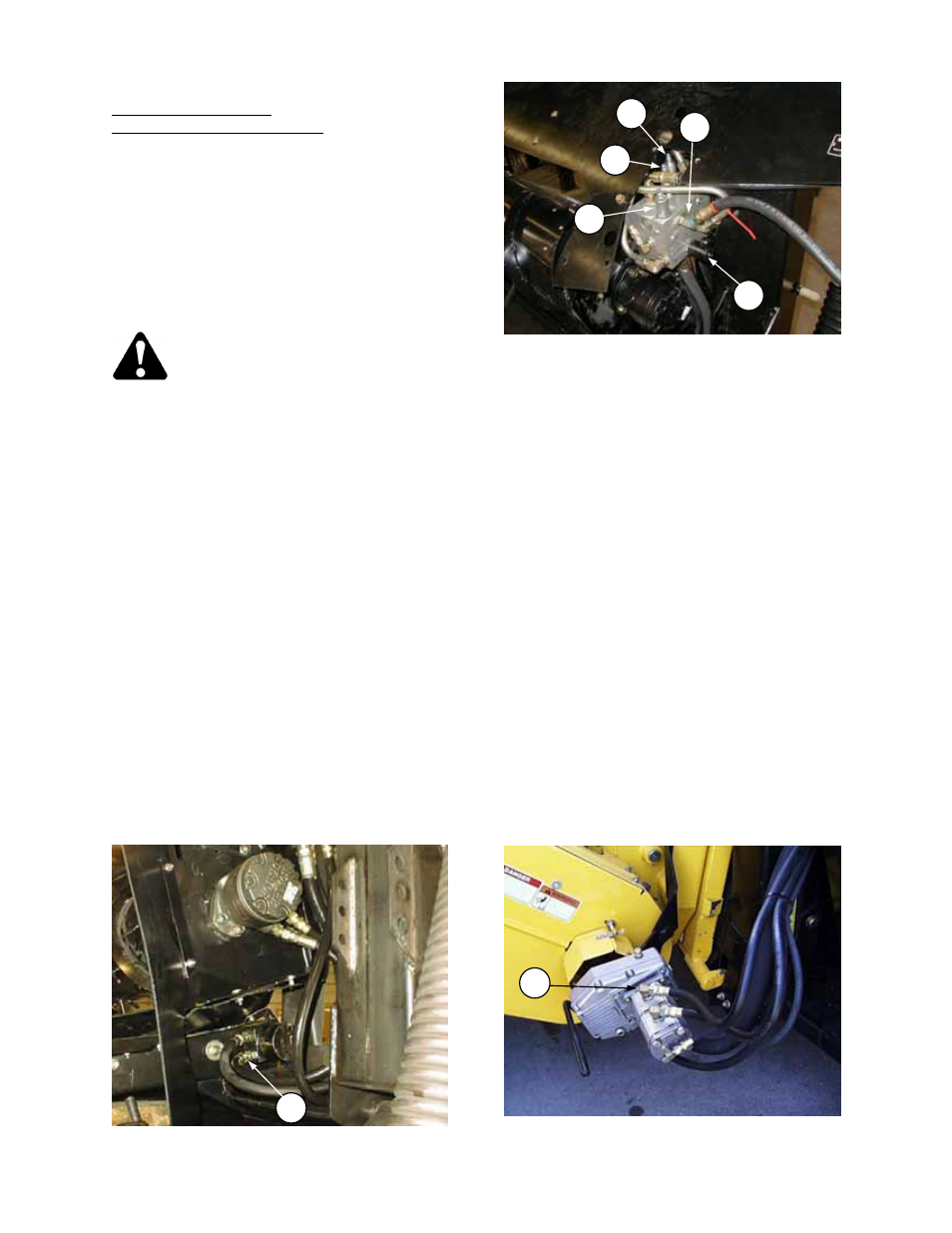

The valve on the combine adapter has three relief

valves for the following functions:

(R1) – 3500 psi (24.1 Mpa) – Feed Draper and

Drum in reverse.

(R2) – 3200 psi (22.1 Mpa) – Feed Draper and

Drum in forward.

(R3) – 2500 psi (17.2 Mpa) – Header Side

Drapers.

A possible cause of insufficient draper/drum speed

is low relief pressure.

WARNING: To avoid bodily injury

from bursting hoses and/or

exploding components, do not

continue closing needle valve if pressure

reading exceeds recommended pressure by

more than 150 psi (1.0 Mpa).

To check header side draper relief pressure:

1. Detach draper drive hoses between adapter

and header. Connect orange to blue at header

for storage.

2. Attach a test fixture consisting of a 5000 psi

(34.5 Mpa) pressure gauge and needle valve

between the orange colour coded hose and the

blue fitting at (A) on adapter. Locate the needle

valve closest to the valve block.

3. Set flow control knob (B) to maximum (number

9 on dial).

4. Run combine engine at operating speed.

5. Engage header drive.

6. Close needle valve until flow stops. Pressure

reading should be 2500 psi (17.2 Mpa).

7. Adjust relief pressure at valve (R3) as required.

To adjust relief valves (R1), (R2) or (R3):

• Loosen jam nut on relief valve.

• Turn relief screw until relief pressure is correct.

• Tighten jam nut.

To check adapter drum & feed draper relief

pressure:

1. Attach a test fixture consisting of a 5000 psi

(34.5 Mpa) pressure gauge and needle valve

between the hose and the lower port of the

feed draper motor at (D). Locate the needle

valve closest to the motor.

2. Attach a 5000 psi (34.5 Mpa) pressure gauge

to service port in tee fitting at (E).

3. Run combine engine at operating speed and

engage feeder house drive in forward.

4. Close needle valve until flow stops. Pressure

reading at pump (E) should be 3200 psi (22.1

Mpa).

5. Adjust relief pressure at valve (R2) as

required.

6. Open needle valve.

7. Disengage feeder house drive and reengage

in reverse.

8. Close needle valve until flow stops. Pressure

reading at draper motor (D) should be 3500

psi (24.1 Mpa).

9. Adjust relief pressure at valve (R1) as

required.

10. Adjust sequence valve if required. See pg. 28.

R1

R2

R3

RELIEF VALVES –

READ GAUGE AT (A) FOR VALVE R3

A

B

E

READ GAUGE HERE FOR VALVE R2

D

READ GAUGE HERE FOR VALVE R1