Assembly preparing the adapter (cont’d.) – MacDon 873 Combine Adapter User Manual

Page 47

Form # 147069

Issue 09/06

45

ASSEMBLY

Preparing the Adapter (cont’d.)

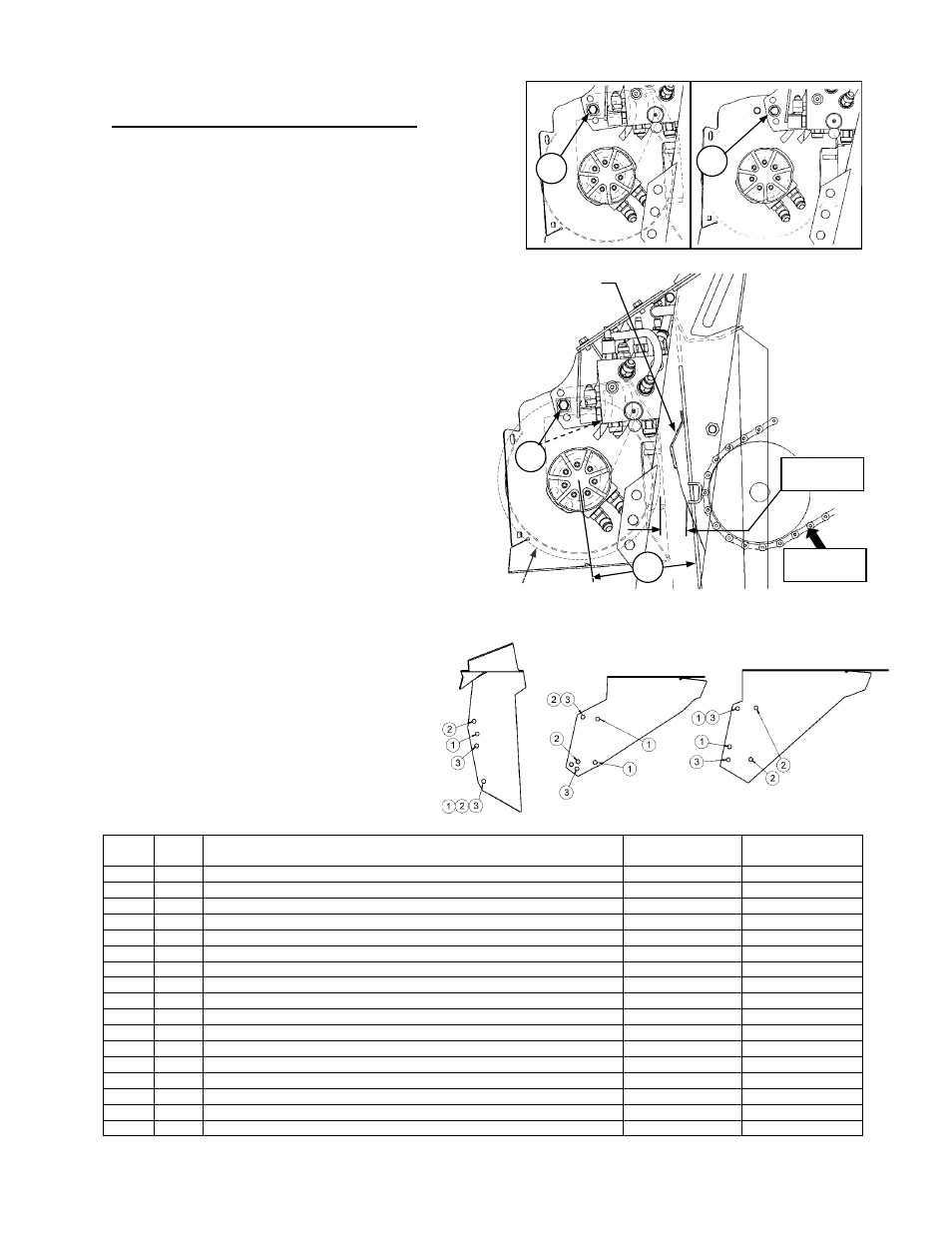

POSITION THE RETRACTING TINE DRUM

Adapters are shipped with drum mounted in the proper fore-aft

range (R) or (F) for your make and model of combine, As well,

the proper fore-aft position is factory set at dimension (X)

(reference only) shown in chart below (except for JD Contour

Master). This is measured from the front side of the panel that

mates with the feeder house face plate to the center of the

drum. This position ensures clearance to the combine feeder

house.

IMPORTANT: For best performance, when adapter is attached to

combine, ensure that clearance between adapter drum and

combine feed drum ranges from 1 to 2 inches (25 to 50

mm), with combine feed drum floated up. Rotate adapter

drum rearward if required to achieve this dimension. After

rotating drum, if Dimension X > 8.5” then locate RTD in

holes (F). If Dimension X < 8.5” then locate RTD in holes

(R).

NOTE: Feeding problems may occur if RTD is rotated

forward of the dimensions shown in chart for your

combine due to the plastic closure panels not fitting

properly.

For 972 Headers: If lower float spring pins are moved

to upper position as described on page 40, relocate

RTD to position (N).

For JD Contour Master rotate drum forward so X =

10.6” (270 mm) to clear welded dust shields. Do not

tighten bolt (M) until combine is attached to adapter.

Adjust float handle to limit float as described on the next

page. See Adapter Mounting Instruction for John Deere

combines at the back of this book for other modifications

required for Contour Master Combines.

To adjust drum fore-aft position, loosen two

mounting bolts (M) each side and swing drum fore-aft

in rear slot. Tighten bolts to secure the position

and remove bolt from hole listed in chart. Place

bolt in new hole after adjusting drum.

*NOTE*: For all combines, removable dust shields

must be removed before operating. For other

combines, dust shields may remain installed with

factory fore-aft setting of the retracting tine drum.

However, if feeding problems are encountered,

remove dust shields and move drum closer to

combine feed drum.

* - Dust shields must be removed from all combines where possible, except John Deere Contour Master.

Poly

Hole

Combine Make & Model

Fore-Aft Range

Dimension X

(factory settings)

C

3

Case 60 Series

R

8.1” (205 mm)*

B

3

Case 77 & 80 Series

R

8.1” (205 mm)*

B

2

CNH AFX

R

8.5” (215 mm)*

A

1

New Holland CX with dust shields

F

8.9” (225 mm)

B

1

New Holland CR 970, 980 with dust shields

F

8.9” (225 mm)

B

3

New Holland CR 970, 980 w/o dust shields

R

8.1” (205 mm)

C

1

New Holland CR 920, 940, 960 with dust shields

F

8.9” (225 mm)

C

3

New Holland CR 920, 940 & 960 w/o dust shields

R

8.1” (205 mm)

A

2

New Holland CX w/o dust shields

R

8.1” (205 mm)**

B 2

Lexion

450, 460R, 470, 470R, 475, 560, 560R, 570R, 575R, 580, 580R

R

8.3” (210 mm)*

A

2

Lexion 460, 465, 480, 480R, 485, 485R & 590R

R

8.3” (210 mm)*

A

3

John Deere (except Contour Master)

F

9.5” (240 mm)*

A

3

John Deere Contour Master

F

10.6” (270 mm)

A

2

John Deere (w/o dust shields)

R

8.1” (205 mm)**

C

2

Gleaner

R

7.5” (190 mm)*

A

2

Challenger 670, Massey Ferguson 9790

R

7.5” (190 mm)*

B

3

Challenger 660, Massey Ferguson 9690

R

7.5” (190 mm)*

N

RTD FORE-AFT RANGES

R

F

POLY HOLE POSITIONS – R/H SHOWN

RTD POSITIONING

M

1” to 2”

(25 to 50 mm)

DUST SHIELDS

(SEE *NOTE*)

DRUM

FLOATED UP

X

FLIGHTING O.D.