Maintenance/service – MacDon 873 Combine Adapter User Manual

Page 34

Form # 147069

Issue 09/06

32

MAINTENANCE/SERVICE

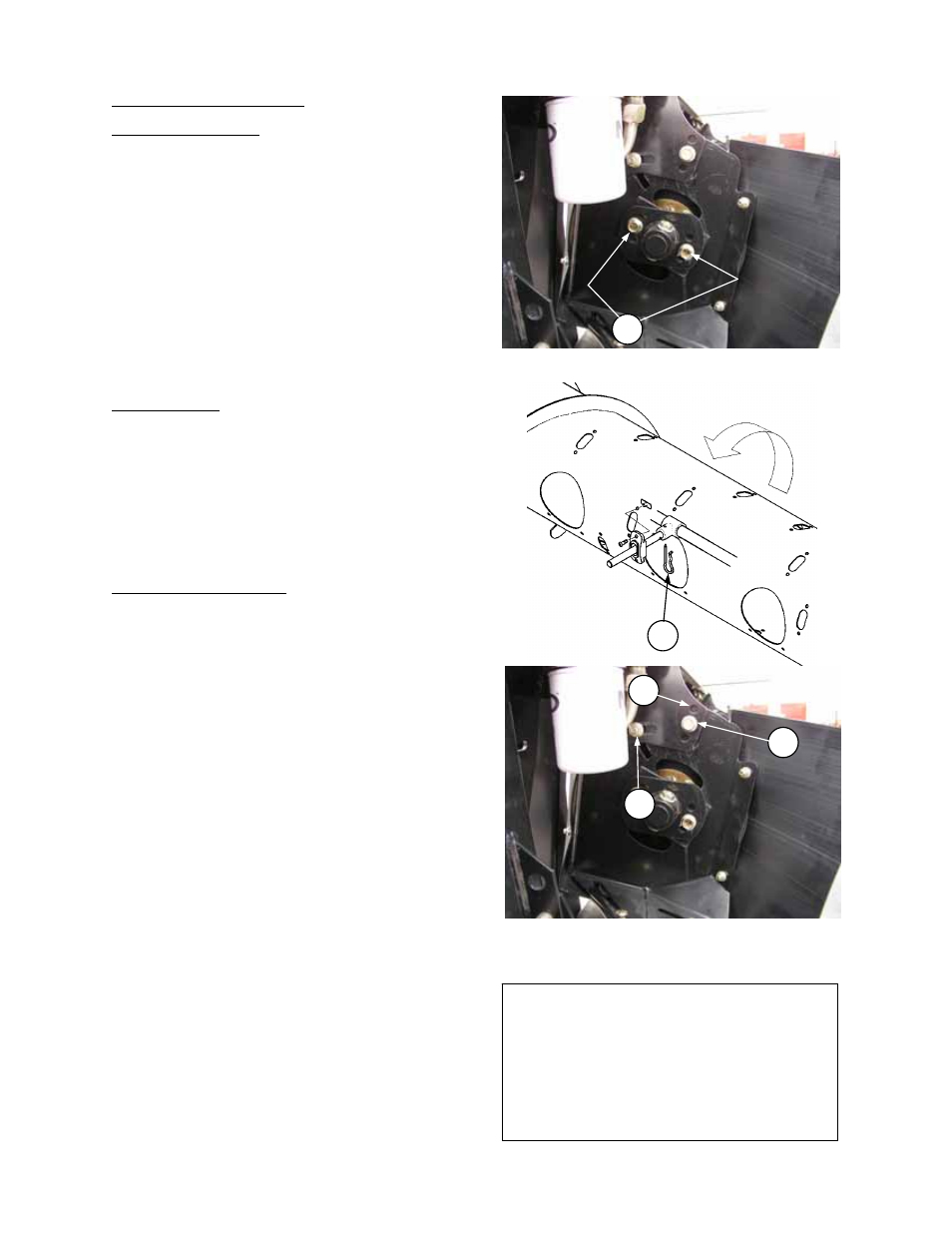

RETRACTING TINE DRUM

Tine Pitch Adjustment – Tines should be fully extended

on the front side of the drum and full retracted on the rear

(feeder house) side.

Tine pitch can be adjusted to change the aggressiveness

of the tines. More aggressive tine pitch means the tines

stay extended for longer as they approach the feed chain

on the combine. Less aggressive means the tines retract

sooner.

IMPORTANT: Always maintain a minimum 3/8” (10 mm)

clearance to header and feed draper with top link fully

retracted and header floated up.

To adjust tine pitch, reposition bolts (A) in cam plate at

right side of adapter. Angling the cam plate further up at

the front decreases tine aggressiveness. Angling the cam

plate down at the front increases tine aggressiveness.

Tine Installation – Depending on deck size, some tines

may have been removed from the drum at the factory to

suit the recommended header side draper opening size.

Should header opening be widened to suit bulky crops,

install tines on outer ends of drum as required to aid

feeding. Always check clearances after adding tines, and

maintain 2” (50 mm) gap from tines to side drapers. When

adding or replacing tines, install hair-pin (C) as shown,

with head leading in direction of drum rotation and

clamping side of pin inboard. Tighten plastic guide

hardware to 75 in. lbs. (8.47 N.m).

Drum Fore-Aft Adjustment – Drum has been shipped in

the proper fore-aft range for your combine. See chart on

page 45. To adjust drum fore-aft position within this range,

loosen two mounting bolts (B) each side. Remove

mounting bolt for plastic deflector (rear bolt for 56” decks &

forward bolt for 38” & 45” decks). Loosen the second

deflector mounting bolt (both sides) and place deflector

bolt in appropriate hole as shown in chart on page 45.

Tighten all deflector hardware. In general, there should be

1 to 2 inches (25 to 50 mm) clearance between adapter

drum and combine feed drum, with combine feed drum

floated up.

NOTE: For best performance, dust shields should be

removed from combine whenever possible. If dust shields

are not removable, adapter drum should be within 1/4 to

3/4 inches (6 to 19 mm) of the dust shield.

IMPORTANT: To prevent damage to drum or feed draper,

always check drum clearance to header frame and feed

draper after adjusting header angle. Flattening the header

angle will reduce the clearance to the drum fingers.

Maintain a 3/8” (10 mm) clearance with top link fully

retracted and header floated up.

Windrowing – When laying a windrow out the end of the

header, move the drum back to clear header backsheet

when it is moved across the center opening. In some

cases it will also be necessary to remove one row of tines

from drum to provide adequate clearance.

For a complete list of steps to convert to windrowing

mode, see “End Delivery” in the Operation section of your

Header Operator’s Manual.

C

TINE INSTALLATION

NOTE: For 963, 973 and 974 Headers only, if

plugging occurs between drum and feed

draper in bulky crops, drum may be raised to

upper hole (E) in frame. Float down stop

must be in Position 2 (973/974) if making this

adjustment. See page 39. Check drum

clearance to header frame after adjusting

drum height.

TINE PITCH ADJUSTMENT

A

DRUM FORE-AFT ADJUSTMENT

B

E

B