Operation – MacDon 873 Combine Adapter User Manual

Page 20

Form # 147069

Issue 09/06

18

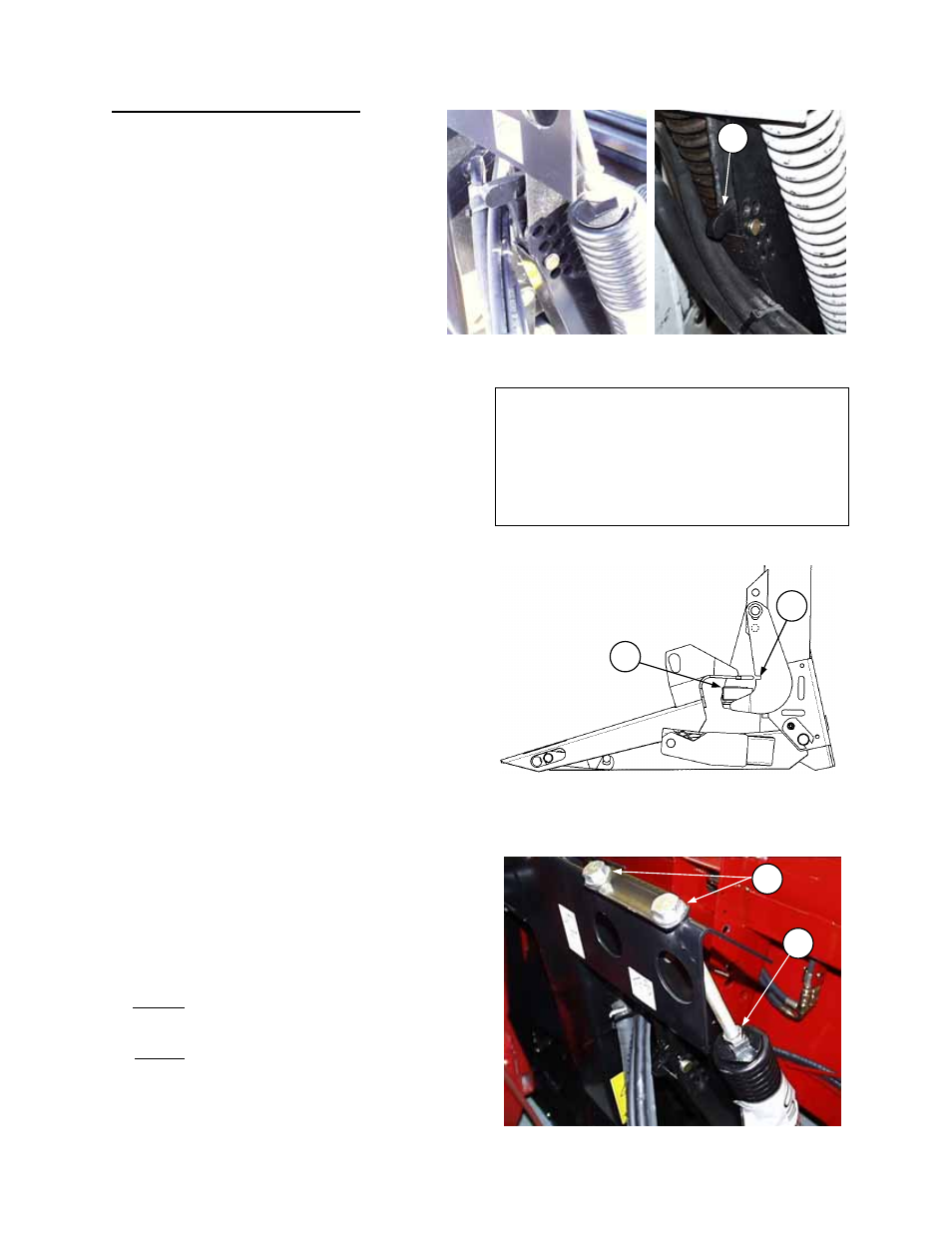

• 0 GAP FOR CUTTING ABOVE GROUND

• ALIGN FLOAT ARM WITH NOTCH FOR

CUTTING ON GROUND (1/2” GAP)

D

A

OPERATION

963/972/973 HEADER FLOTATION

NOTE: For float adjustment when working

with the 974 Flex Header, see the Header

Operator’s Manual.

IMPORTANT: Set header float as light as

possible without causing excessive bouncing.

This avoids:

- frequent breakage of sickle components

- scooping soil

- soil build-up at cutterbar in wet conditions,

To check header float:

1. Raise feeder house and engage lift

cylinder stops.

2. Move handle down to engage float as

shown at (E), both sides. If pin is tight, extend

top link to free it up.

3. Set top link to mid-range length (19-1/4”) (490 mm).

4. Disengage lift cylinder stops and lower header

so the cutterbar is 1 to 6 inches (25 to 150 mm)

above the ground.

5. With cutterbar 1 to 6 inches (25 to 150 mm)

above the ground, grasp the crop divider rod and

lift up. Under normal conditions, when cutting

above the ground, it should require about 50 - 70

lbs. force (225 - 315 N) to lift divider at either

end. Cutting on the ground requires lighter float,

approximately 30 lbs. (135 N) at each divider

point.

TIPS:

• For cereal grain crops where you will be

working with cutterbar off ground, float

arm should be touching down stop at (A).

• For soybeans or other crops where you

will be working with cutterbar on

ground, gap between float arm and

down stop should be 1/2” (13 mm) as

illustrated. Notch (D) is provided as an

alignment aid for this setting.

See next page for operating tips when

cutting on the ground:

To adjust header float:

1. Raise feeder house and engage lift cylinder

stops.

2. Loosen jam nuts (B), two per side.

3. Tighten bolts (C) at both sides of adapter to

increase float (which makes header lighter

when lowered to ground).

Loosen bolts to decrease float (which makes

header heavier when lowered).

4. Tighten jam nuts (B).

NOTE: Once float is set, float lockout is engaged

by raising handle as high as possible, then

aligning the closest hole for installation of pin. The

float lock-out position shown above is “as

shipped”. This position is only necessary when

adapter is being removed from header (or installed

in header).

FLOAT LOCKOUT

FLOAT ENGAGED

ADAPTER FLOAT

E

FLOAT ADJUSTMENT

B

C