Maintenance/service – MacDon 873 Combine Adapter User Manual

Page 28

Form # 147069

Issue 09/06

26

MAINTENANCE/SERVICE

SEALED BEARING INSTALLATION

1. Clean shaft and coat with rust preventative.

2. Install flangette, bearing, flangette and lock

collar. The locking cam is only on one side of

the bearing.

3. Install and tighten the flangette bolts.

4. When the shaft is located correctly, lock the

lock collar with a punch. The collar should be

locked in the same direction the shaft rotates.

Tighten the set screw in the collar.

5. Loosen the flangette bolts on the mating

bearing one turn and re-tighten. This will allow

the bearing to line up.

GREASING THE ADAPTER

See “Recommended Lubricants” in this section for

recommended greases.

The adapter has eight greasing points as shown

below and on the following page. Use the hour

meter in the combine cab and the “Maintenance

Checklist” provided to keep a record of scheduled

maintenance.

Procedure:

1. Wipe grease fitting with a clean cloth before

greasing, to avoid injecting dirt and grit.

2. Inject grease through fitting with grease gun

until grease overflows fitting.

3. Leave excess grease on fitting to keep out dirt.

4. Replace any loose or broken fittings immedi-

ately.

5. If fitting will not take grease, remove and clean

thoroughly. Also clean lubricant passageway.

Replace fitting if necessary.

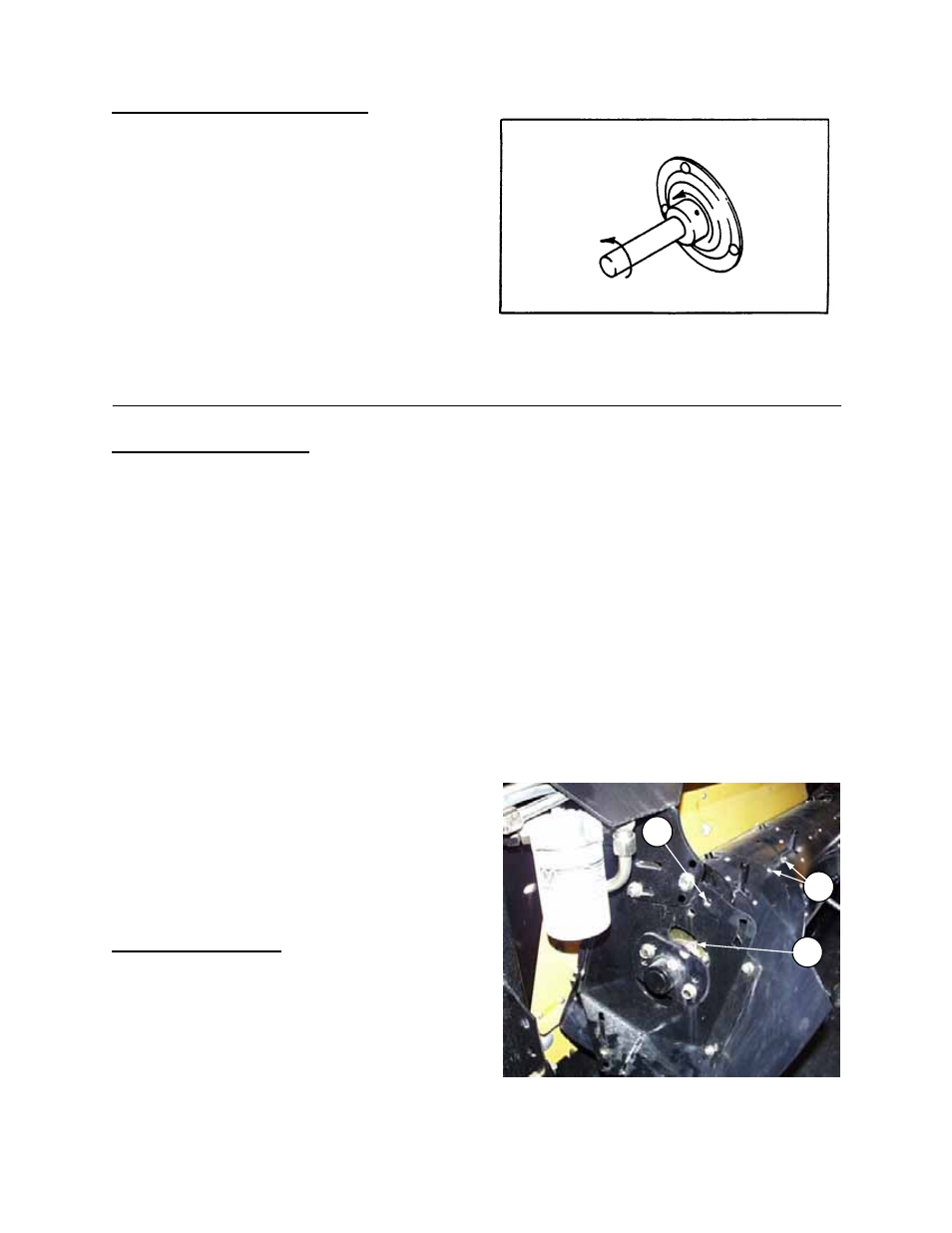

100 Hours or Annually:

1. Drum Bearing (A) – one fitting

NOTE: Alignment of fitting with opening may be

difficult when header is attached. Aligning drum

access cover bolts (B) with hole (H) in drum

support plate will properly align fitting.

TIGHTEN COLLAR IN DIRECTION

SHAFT ROTATES

DRUM BEARING

A

B

H