Assembly, Preparing the adapter (cont’d.) – MacDon 873 Combine Adapter User Manual

Page 44

Form # 147069

Issue 09/06

42

ASSEMBLY

Preparing the Adapter (cont’d.)

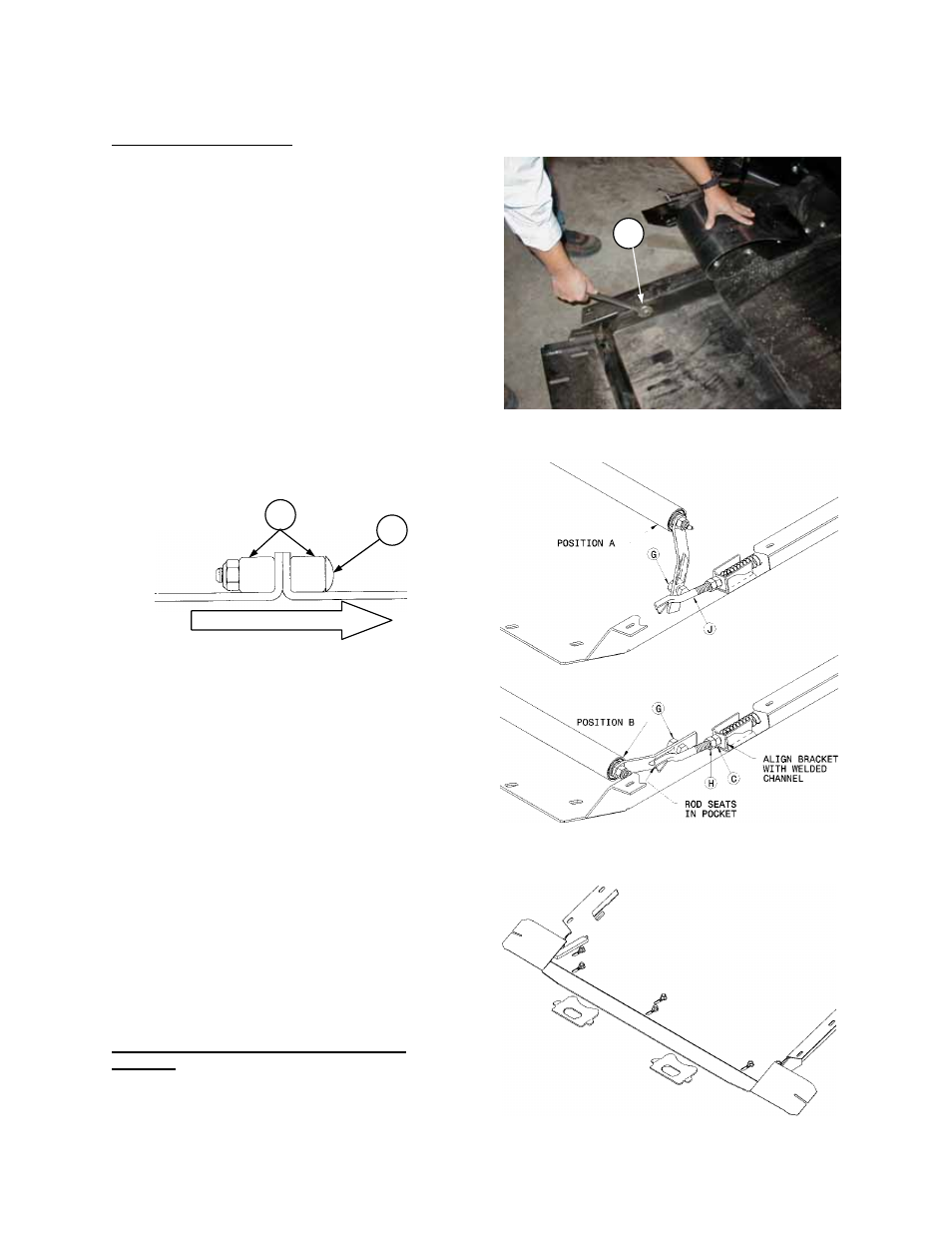

INSTALL FEED DRAPER

1. Pull front of plastic panel up and back, well away

from idler roller and tightener mechanism.

2. Loosen nut (G), both sides, and pull up on idler roller

to rotate to position (A). Nut (G) must be loose

enough that idler arm easily passes by adjusting rod

(J).

NOTE: Rod (J) may come out of position when lifting

idler roller. It will return to proper position when roller

is moved to working position (B). Try moving idler

roller from position (A) back to working position (B). If

roller does not pivot over, loosen nut (G) further.

When nut (G) is properly loosened, pull roller up to

position (A) for installation of draper.

3. Install feed draper on adapter rollers, ensuring belt

on underside seats properly on left side of both

rollers.

4. Pre-install screws (F) in connector slat. Screws fit

tightly into slat holes. To install, support slat on both

sides of hole and hammer screw into hole. Position

connector slats (D) as shown below with heads

leading in direction of travel.

5. Apply draper tension as follows:

a. With nut (G) loosened per step 2, swing roller from

position (A) to working position (B), standing on

ends of roller if necessary. Take care not to

damage roller or draper seal.

b. Back off nut (H) and adjust position of nut (C) to

align bracket with welded channel as shown. This

position provides proper spring tension. Tighten nut

(H) against nut (C) to secure the position. Repeat at

other side.

c. Tighten nut (G), both sides, ensuring that formed

end of adjusting rod seats properly in pocket

formed into idler arm and that rod is positioned at

bottom of cut-out in side of pan.

6. Attach front end of plastic panels to front of feed

deck with four screws provided (two per side,

heads on top).

IMPORTANT: Panel hardware should not be over

tightened. Tighten locknuts to close gap between

plastic panel and feed deck flange, yet still allow

screw to move in flange slot.

INSTALL SKID/TRANSITION PLATE – 963

HEADER

Attach skid/transition plate to adapter feed pan, using 1/2

x 1 inch carriage bolts and flange nuts as shown. Position

hardware at rear of slots and leave finger tight. When

attaching to header, adjust skid/transition plate to suit

your combine make and model as described on page 12.

FEED DRAPER CONNECTION

F

D

DIRECTION OF TRAVEL

LOOSEN IDLER ROLLER HARDWARE

G

APPLY DRAPER TENSION

INSTALL SKID/TRANSITION PLATE – 963