Header attaching & detaching – MacDon 873 Combine Adapter User Manual

Page 15

Form # 147069

Issue 09/06

13

HEADER ATTACHING & DETACHING

DETACHING HEADER FROM COMBINE AND ADAPTER

Using this procedure, adapter will remain attached to

the combine. Instructions for detaching both header

and adapter from combine are given on page 15.

1. Choose a level area. Lower the reel and raise

the header so that cutterbar is about 18” off the

ground. Stop engine and remove key.

DANGER: To avoid bodily injury from

fall of raised header, engage header

lift cylinder stops when working on or

around raised header. See your

Combine Operator's Manual for

details.

DANGER: Wait for all movement to

stop. A rotating driveline can cause

entanglement resulting in serious

personal injury or death.

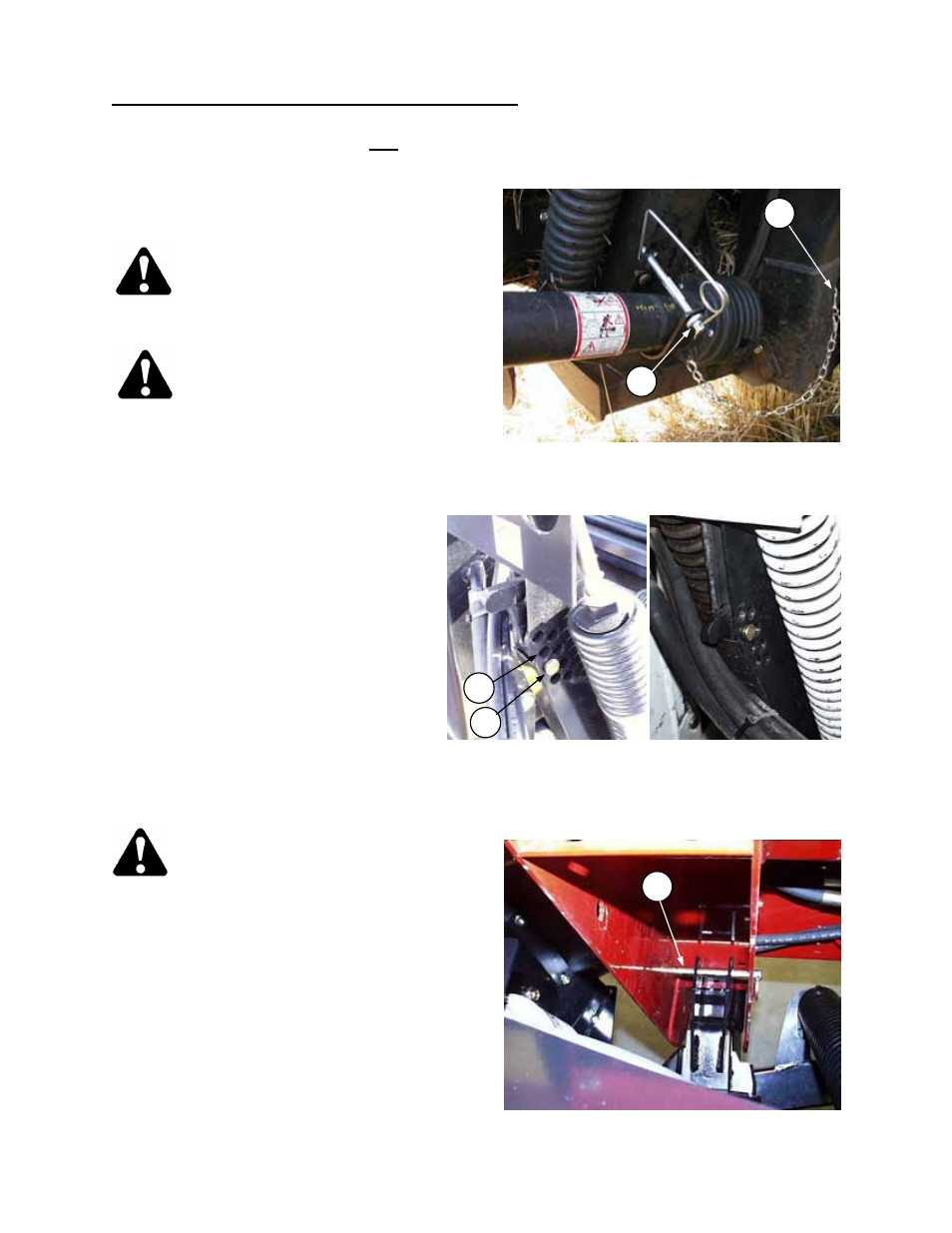

2. Disconnect driveline from feeder house shaft.

Detach chain at (A), remove pin (C) and store

this end of driveline on header frame tube by

securing or supporting at hydraulic/electrical

bracket. Ensure storage location does not

interfere with backing adapter out of header.

Reinstall pin (C).

3. Disconnect hydraulic lines:

• Reel lift between header and combine.

• Reel drive pressure and reel return between

header and combine.

• Draper return (blue) and draper drive

pressure (orange) between adapter and

header.

• Reel fore-aft / Header Tilt hoses between

header and combine (if equipped).

NOTE: Some combines are equipped with

multi-link couplers that connect several

hydraulic and electrical circuits at once.

IMPORTANT: Couple or cap all lines to prevent

hydraulic system contamination except as noted

in Warning below. Be sure header stored hoses

and combine stored hoses are not entangled.

WARNING: For headers with hydraulic

reel fore-aft, never connect the fore-aft

couplers to each other. This would

complete the circuit and allow the reel

to creep forward in transport, resulting in

instability.

4. Disconnect wiring harness between header and

combine. Cap harnesses to prevent moisture

from entering plugs.

5. Remove clevis pin from adapter float and move

handle up to “float lockout” position. Install pin in

hole (E) for 963/973/974 Headers, and hole (F)

for 972 Header. Install clevis pin and lynch pin.

Repeat at other side.

6.

Remove clevis pin (B) from adapter lock

position. Repeat at other leg. Place pins in

storage hole higher up on leg.

B

REMOVE PINS LOCKING ADAPTER TO

HEADER

FLOAT LOCKOUT

FLOAT ENGAGED

ADAPTER FLOAT

E

F

DETACH DRIVELINE & STORE ON HEADER

A

C