Operation – MacDon 873 Combine Adapter User Manual

Page 23

Form # 147069

Issue 09/06

21

OPERATION

963/972/973 HEADER FLOTATION (continued)

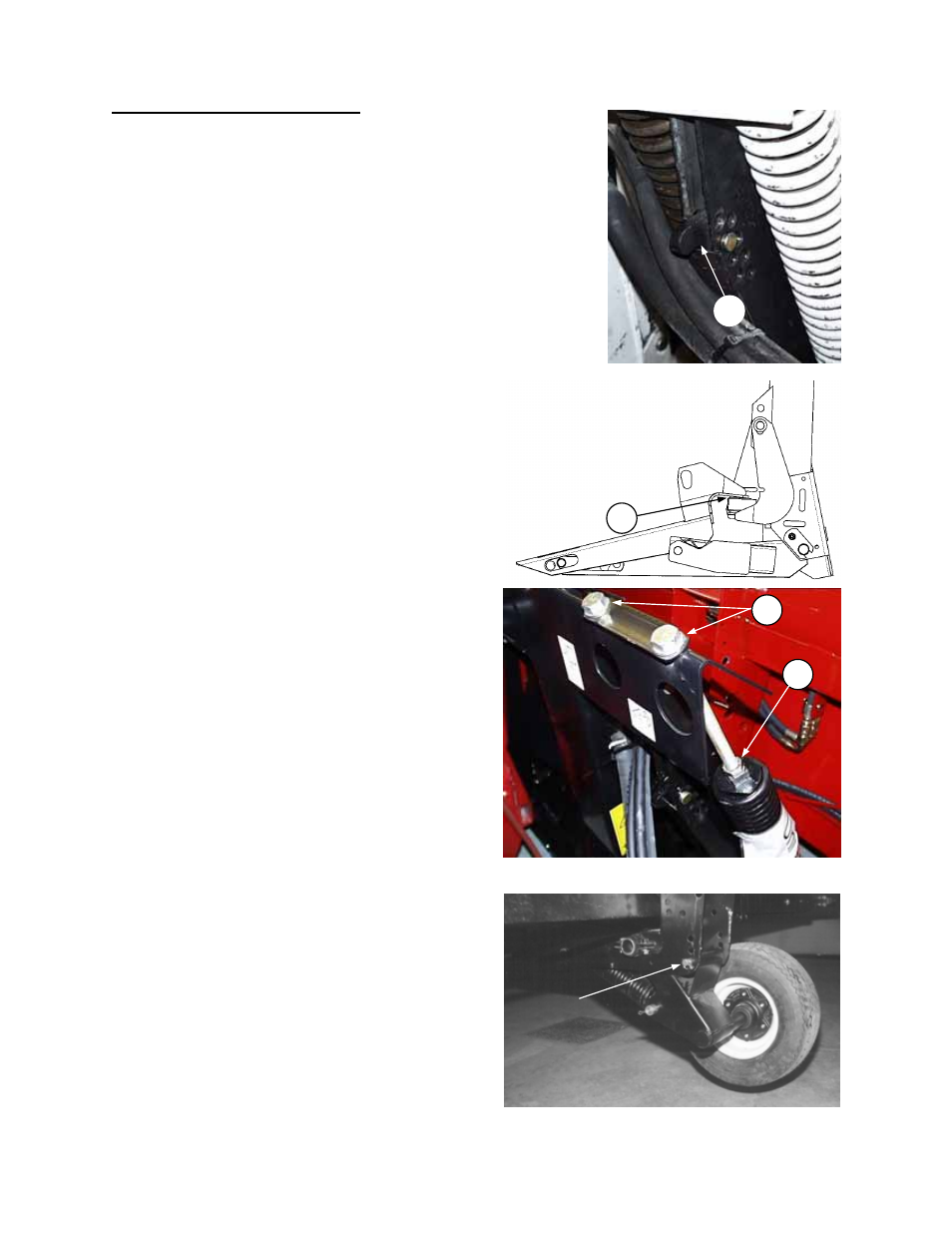

Header Floatation for 972/973 Headers with Gauge

Wheel/Transport Wheel:

1. Set guard angle and reel to desired position for cutting conditions

and slide handle (A) down to engage float.

2. Lower header to remove the pins from the gauge wheels

3. Position the header at the desired cutting height (without gauge

wheel pins in).

At this position inspect the gap at (B) to ensure that

the gauge wheel springs are not pushing the header

off the float down-stop pads. If gap at (B) is between

0 to 1/2 inch (0 to 13 mm) proceed to step 4.

If gap at (B) is larger than 1/2 inch, lift up on crop

divider to check the header’s floatation. If float is

lighter than 100 lbs (445 N) continue on with setting

procedure, if not check to see how many coil springs

are installed in the gauge wheels. If two springs are

installed remove one spring from each side and

repeat step 3.

4. Adjust float to desired setting [recommended 80

to 100lbs (355 to 445N) while keeping 0 to 1/2

inch (0 to13 mm) gap at (B). Measure gap with

header at desired cutting height.

Loosen jam nuts (D) and turn adjustment bolts (C)

clockwise to increase float.

Loosen jam nuts (D) and turn adjustment bolts (C)

counterclockwise to decrease float.

5. With header at cutting height, inspect position of

gauge wheel retaining slot. Insert pin into the hole

that is most centered in the slot.

Transport package uses a different bracket however,

there is still a slotted hole to place the pin through.

Utilize the same steps to set the height.

NOTE: If slot is positioned above the top hole, place

the wheels into storage position and lower skid

shoes to cut in the close proximity to the ground.

Refer to Floatation Setting section.

NOTE: Settings may require re-adjustment after an

adjustment to header angle or reel position.

ADAPTER FLOAT ENGAGED

A

B

FLOAT ADJUSTMENT

D

C