Operation – MacDon 873 Combine Adapter User Manual

Page 25

Form # 147069

Issue 09/06

23

OPERATION

HEADER ANGLE

The header (or guard) angle can be adjusted flatter or steeper to suit your conditions. Angle range varies with

combine set-up, tire size, adapter down stop position, etc.

See Combine Operator's Manual for header levelling and additional header angle adjustments. For combines

with adjustable face-plate angle, see “Adjustments and Checks” on page 50 to determine if adjustment to face

plate angle is required.

IMPORTANT: A flat header angle is recommended for normal conditions. A flatter header angle reduces sickle

section breakage and reduces soil scooping or build-up at the cutterbar in wet conditions. Use a steeper angle

to cut very close to the ground, or in down crop for better lifting action. The Model 973 and 974 headers have

been designed so the guard angle is flatter than the draper angle. This allows operating at a mid-range header

angle while still benefiting from a flat guard angle.

IMPORTANT: Always check adapter drum clearance to header frame after adjusting header angle. Flattening

the header angle will reduce the clearance to the drum fingers. For units with hydraulic top link, fully retract the

cylinder to check finger clearances.

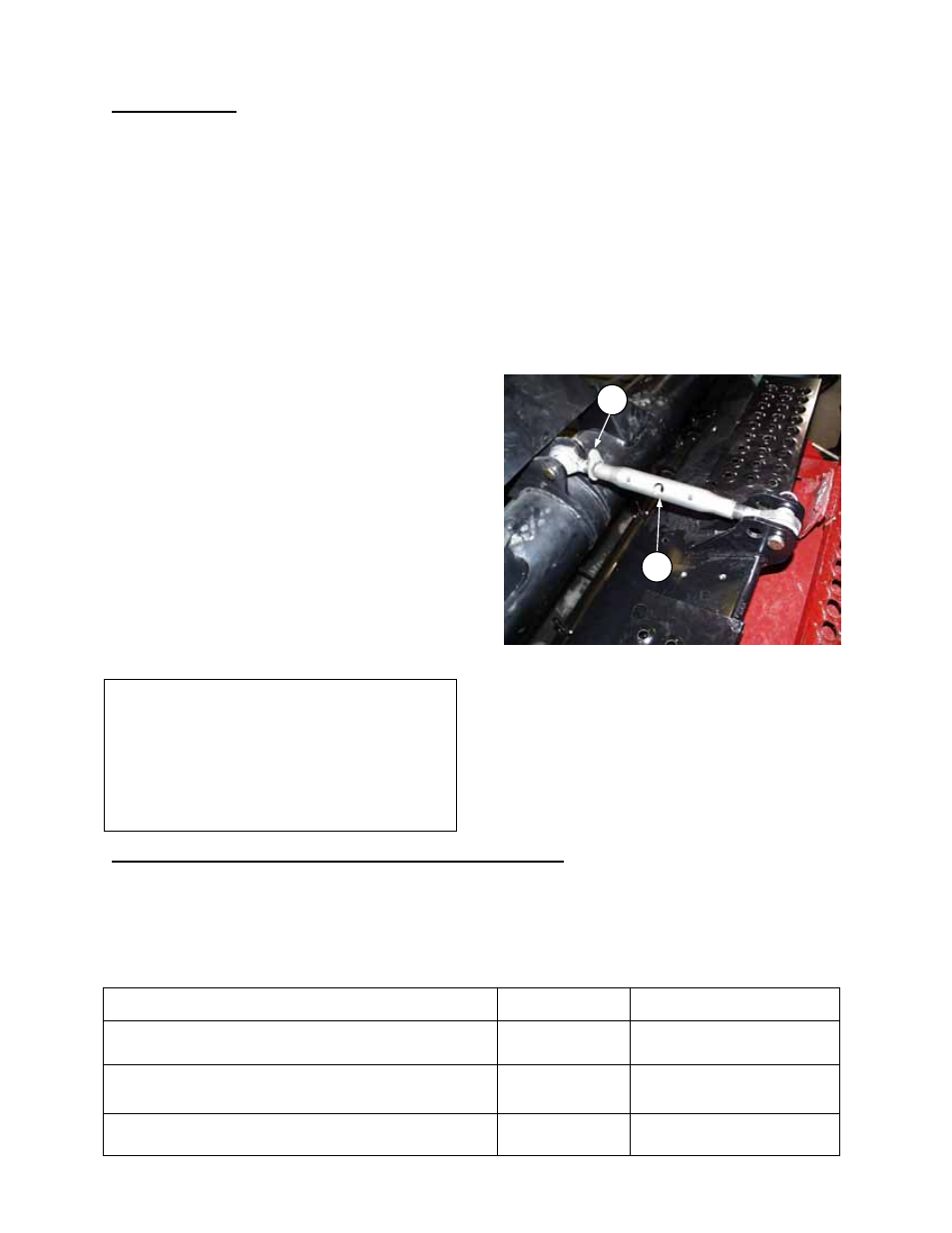

To adjust header angle with mechanical link

(972 & 973 Headers):

1. Lower cutterbar to ground and continue

lowering to drop feeder house another 2 to 5

inches (50 to 125 mm).

2. Back off the locking collar (A) on top link

turnbuckle.

3. Using a punch in hole in turnbuckle (B), turn to

adjust header angle.

Longer top link = steeper header angle

4. At desired adjustment, tighten locking collar (A)

securely against turnbuckle to fix the position.

Collar should point up as shown to prevent

contact with header frame when header floats

fully up.

HEADER ANGLE HYDRAULIC ADJUSTMENT

An optional kit is available for 972 and 973

Headers which allows adjustment of header angle

from the combine cab by means of a hydraulic

cylinder. This is standard equipment for the 974

Header.

See “Unloading and Assembly” section for

information on assembly and use of this option.

WIDENING THE DELIVERY OPENING (973/974 Headers Only):

In conditions where severe “bridging” is occurring (bulky crop being thrown across the opening), widen the

header side draper opening to allow the crop to fall onto the feed draper. See “Delivery Opening” in your

Header Operators’ Manual for procedure. To achieve smooth feeding after widening opening, add

outboard tines to the adapter drum. See “Tine Installation”, page 32.

NOTE: Check clearance to ensure that RTD fingers will not contact side drapers.

Combine Model

New Delivery

Opening

Qty. of tines to be

added to drum

John Deere, New Holland CX, Lexion (Wide Decks)

1620 mm (63.7”)

2 per side (4 total)

Case 77/80/88, CNH AFX,

New Holland CR 970/980, Lexion (Mid-Size Decks)

1265 mm (49.8”)

2 per side (4 total)

Case 60/66, New Holland CR

1165 mm (45.9”)

2 per side (4 total)

HEADER ANGLE

MECHANICAL ADJUSTMENT

A

B