Operation – MacDon 873 Combine Adapter User Manual

Page 24

Form # 147069

Issue 09/06

22

OPERATION

HEADER LEVELLING

NOTE: The following applies if gap (A) is zero. If float is set light (operating cutterbar on ground), then level

header by adjusting main float springs.

Adjust header levelling with header at the flattest angle. See Header Angle, next page.

1. With header on level ground, lower header so cutterbar is 2 to 4 inches (50 to 100 mm) off the ground.

2. Check level of header by measuring cutterbar to ground at both ends.

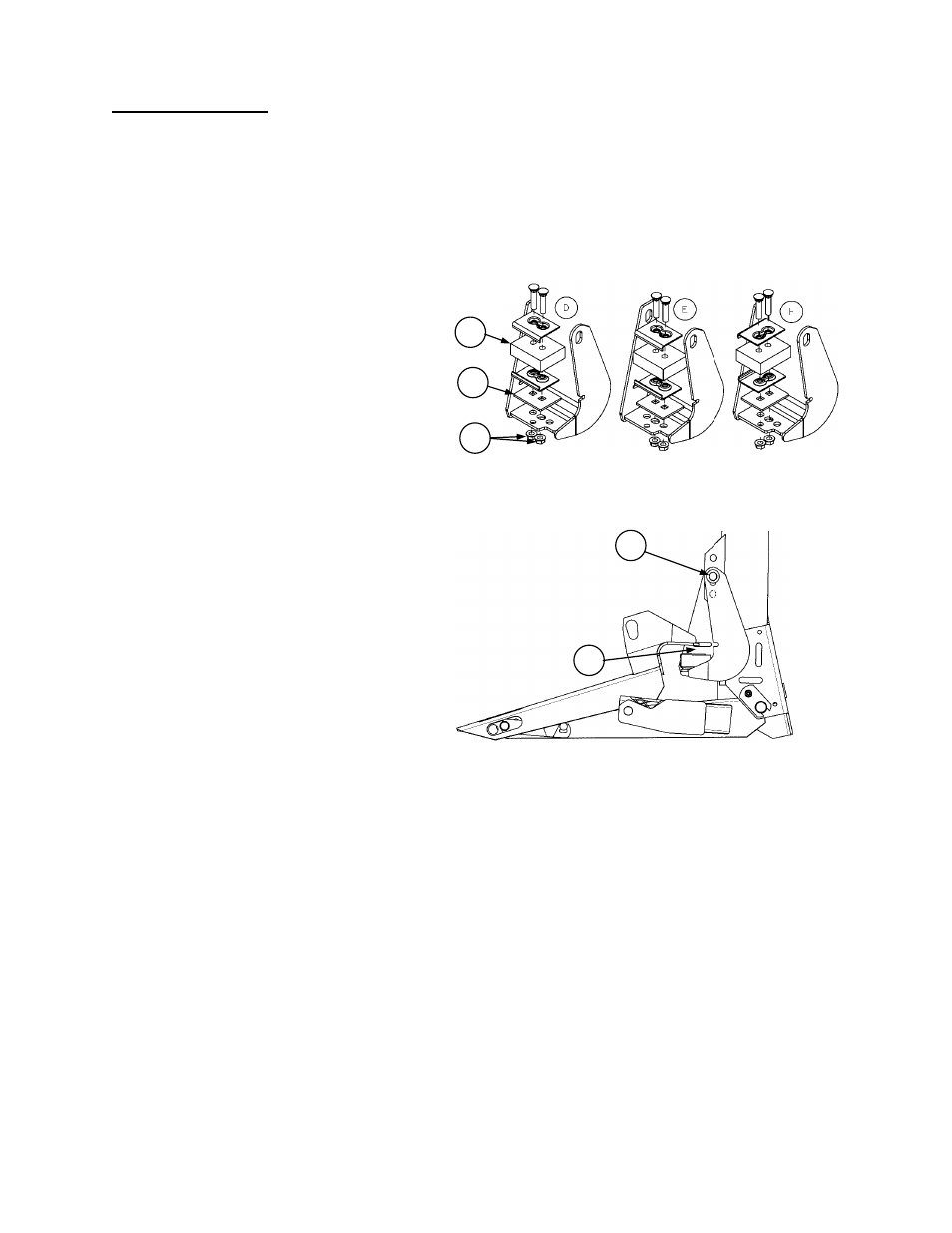

3. To lower cutterbar on one end, remove a shim (C) from under rubber pad (B) in down stop assembly.

Adjust shim quantity side to side, placing from 0 to 2 shims to level header.

To add or remove a shim:

•

Lower cutterbar to ground and continue

lowering feeder house so gap at (A)

increases.

•

Remove nuts (H), disassemble and add or

remove shim(s) as required.

•

Reassemble and adjust header flotation to

gap (A) setting recommended in Header

Floatation section. Note the different

positioning of the pad assembly on the

support, depending on header model and

combine configuration:

•

963/972 mounted on combines with

dust shields removed – position (D) –

inboard set of side-by-side holes.

•

963/972 mounted on combines with

dust shields on – position (F). – fore-aft

set of holes.

•

973 on all combines – position (D) –

inboard set of side-by-side holes.

•

974 on all combines – position (E) –

outboard set of side-by-side holes.

NOTE: To simplify this procedure: With header

adjusted to steepest angle (longest top

link length) and fully floated, the entire

down stop assembly can be removed by

removing pin (G).

G

A

HEADER LEVELLING - L/H SHOWN

(DOWN STOP PAD ORIENTATION)

B

C

H