Maintenance/service header drive – MacDon 9352c SP User Manual

Page 96

Form # 147459

Issue 11/06 Web Rev_01

94

MAINTENANCE/SERVICE

Header Drive

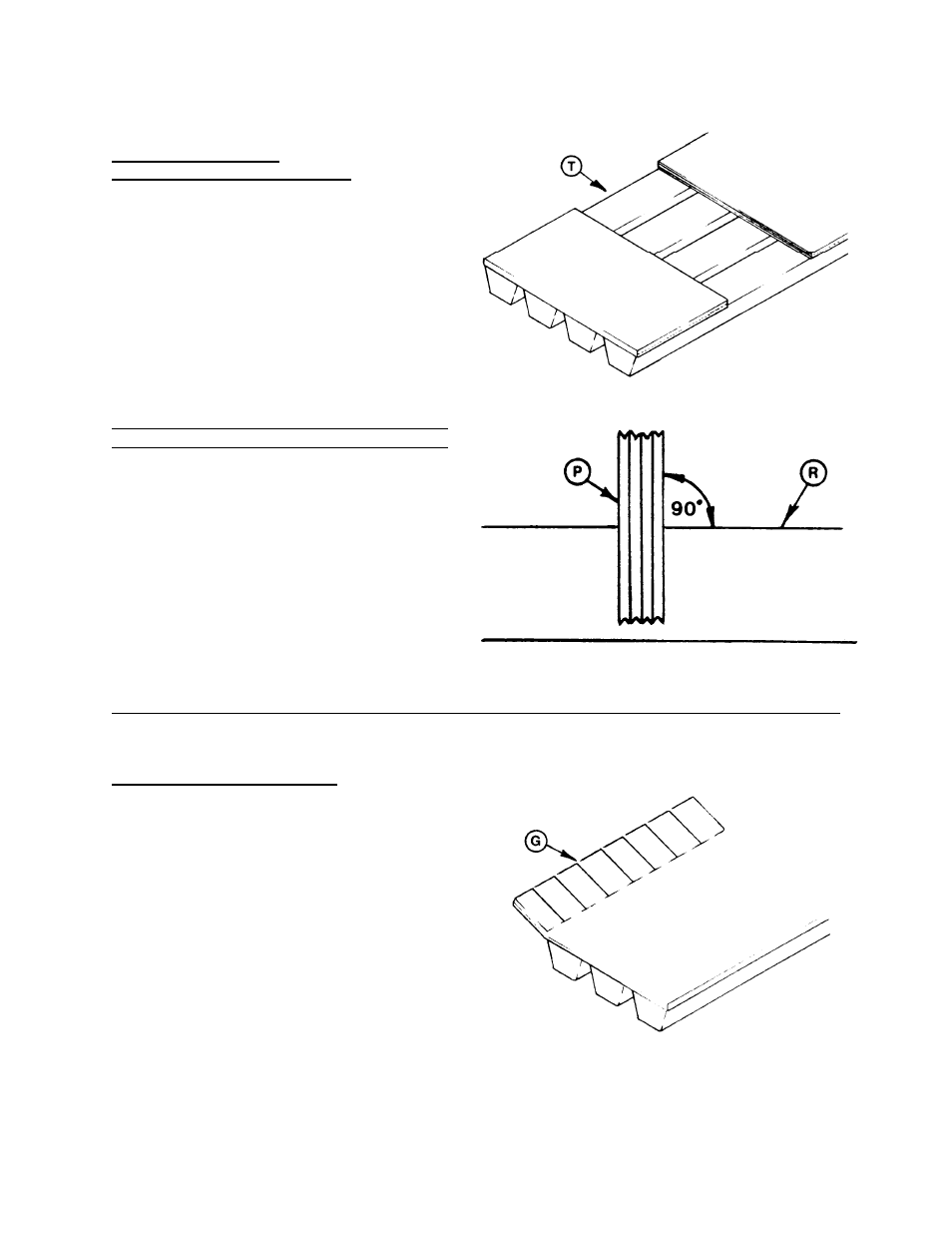

HEADER DRIVE BELT:

PULLEY VERTICAL ALIGNMENT

Vertical misalignment of front pulley can cause a

belt failure where sections of the backing band are

missing, as shown at (T). The missing sections will

vary from 1/2 inch to 5 feet long. Failure starts with

cracks across the backing band from one side to

the other, followed by pieces falling off.

Front pulley (P) and two flat idlers must be

vertically square (90

°) to rectangular frame tube

(R) as shown.

To adjust front pulley, shim the pulley mounting

plate at both top bolts, or both bottom bolts

depending on the direction of the misalignment.

To adjust flat idlers, bend mounting arms to suit. (It

may be necessary to heat idler arms to permit

adequate bending.)

HEADER DRIVE BELT GUIDES

Improper adjustment of belt guides can cause belt

to jump one pulley groove. This will result in a belt

failure characterized by one outer portion of

backing band being frayed and separated from

one V-belt as shown at (G). The other V-belts will

still be attached to band and the band will not be

cracked through from side to side.

Belt guides for the header drive belt should be

adjusted so they do not rub belt when drive is

engaged, but still support belt when drive is

disengaged.

See adjustment details, next page.

BELT FAILURE DUE TO VERTICAL MISALIGNMENT

FRONT PULLEY & IDLERS SQUARE

TO RECTANGULAR FRAME TUBE

BELT FAILURE DUE TO JUMPING GROOVE