Operation, Header angle, Header tilt hydraulic adjustment – MacDon 9352c SP User Manual

Page 50

Form # 147459

Issue 11/06 Web Rev_01

48

OPERATION

Header Angle

Header angle is adjustable by changing the length

of the center link between header and tractor.

Header angle adjustment ranges:

910, 920, 930 Series Headers: 8

° to 16°

940 Series Headers: 6

° to 13°

960 Series Headers: 13

° to 21°

970 Series Headers: 9.5

° to 21°

NOTE: Above figures are guard angle in degrees

below horizontal.

IMPORTANT: A flatter header angle is recom-

mended for normal conditions. A flatter angle

reduces sickle section breakage and reduces soil

build-up at the cutterbar in wet conditions.

Use a steeper angle to cut very close to the

ground, or for better lifting action of down crops.

IMPORTANT: Changing header angle will affect

flotation. Steepening the header angle makes

header heavier while flattening the header angle

makes header lighter. Always check flotation after

adjusting header angle.

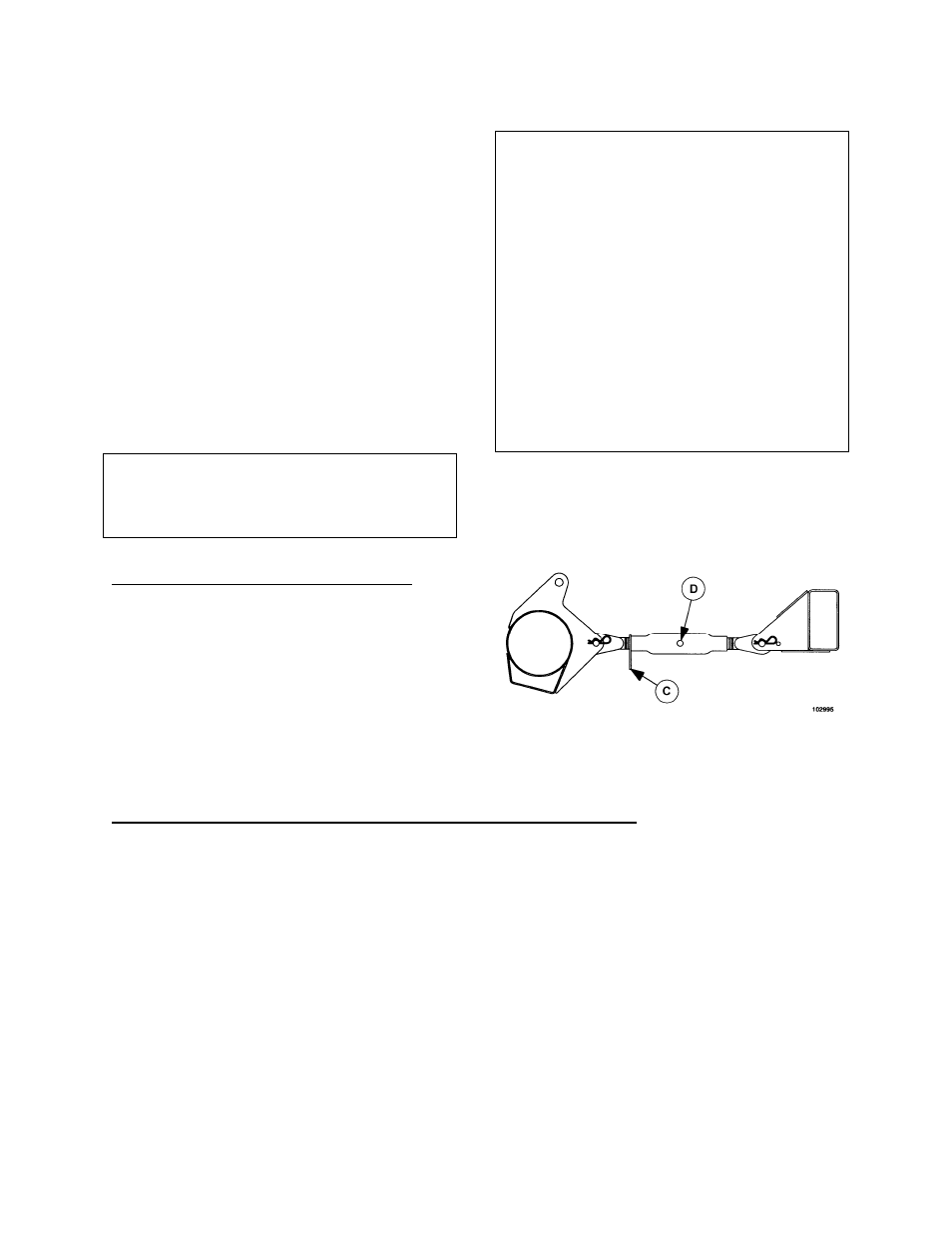

To adjust header angle with mechanical link:

1. Unlock collar (C) by tapping it in a counter-

clockwise direction.

2. Using a long punch in hole (D), turn the center

link until the desired header angle is reached.

Shortening the link will give a flatter header

angle, while lengthening the link provides

steeper angles.

3. Lock collar (C) against link body by tapping in a

clockwise direction to secure the position.

HEADER TILT HYDRAULIC

ADJUSTMENT

An optional kit is available which allows adjustment

of header angle from the cab by means of a

hydraulic cylinder.

See “Options and Attachments” section for order

numbers. See “Header Controls” in Operator’s

Station section for identification of hydraulic

header angle controls.

IMPORTANT: For units with hydraulic header tilt

option, be aware that when cutting on the ground

and using the hydraulic center link to adjust header

angle on the go, the flotation will be affected. To

prevent excessive guard breakage when

conditions are not suited to heavier float (e.g.

rocky or wet), do not use the tilt control on the go.

Instead, use the header height switch as described

below.

To adjust header angle when cutting on the ground (without hydraulic option):

When cutting with header on the ground, the header height switch can be used to adjust header angle "on the

go". Familiarize yourself with how the header reacts during this adjustment to take full advantage of the

feature.

1. Lower header by pressing bottom of header height switch until cutterbar just touches ground. At this point,

cutterbar is at the flattest guard angle.

2. If a steeper angle is desired, continue pressing bottom of switch. This will steepen the guard angle until lift

cylinders are fully retracted.

3. To adjust angle from steeper to flatter, press the top of the header height switch to extend cylinders a small

amount. Once the flattest angle is reached, further activating the switch will lift the cutterbar off the ground.

Use this adjustment in combination with the center link adjustment (above) to achieve the desired range

through which the header angle moves before header lifts off the ground.

See "Header Controls" in Operator's Station section for use of header height switch and cut height indicator

with regard to header angle.

HEADER ANGLE MECHANICAL ADJUSTMENT