MacDon 9352c SP User Manual

Page 92

Form # 147459

Issue 11/06 Web Rev_01

90

MAINTENANCE/SERVICE

Hydraulic System: Header & Reel Lift

CYLINDER CONTROL VALVE RELIEF PRESSURE

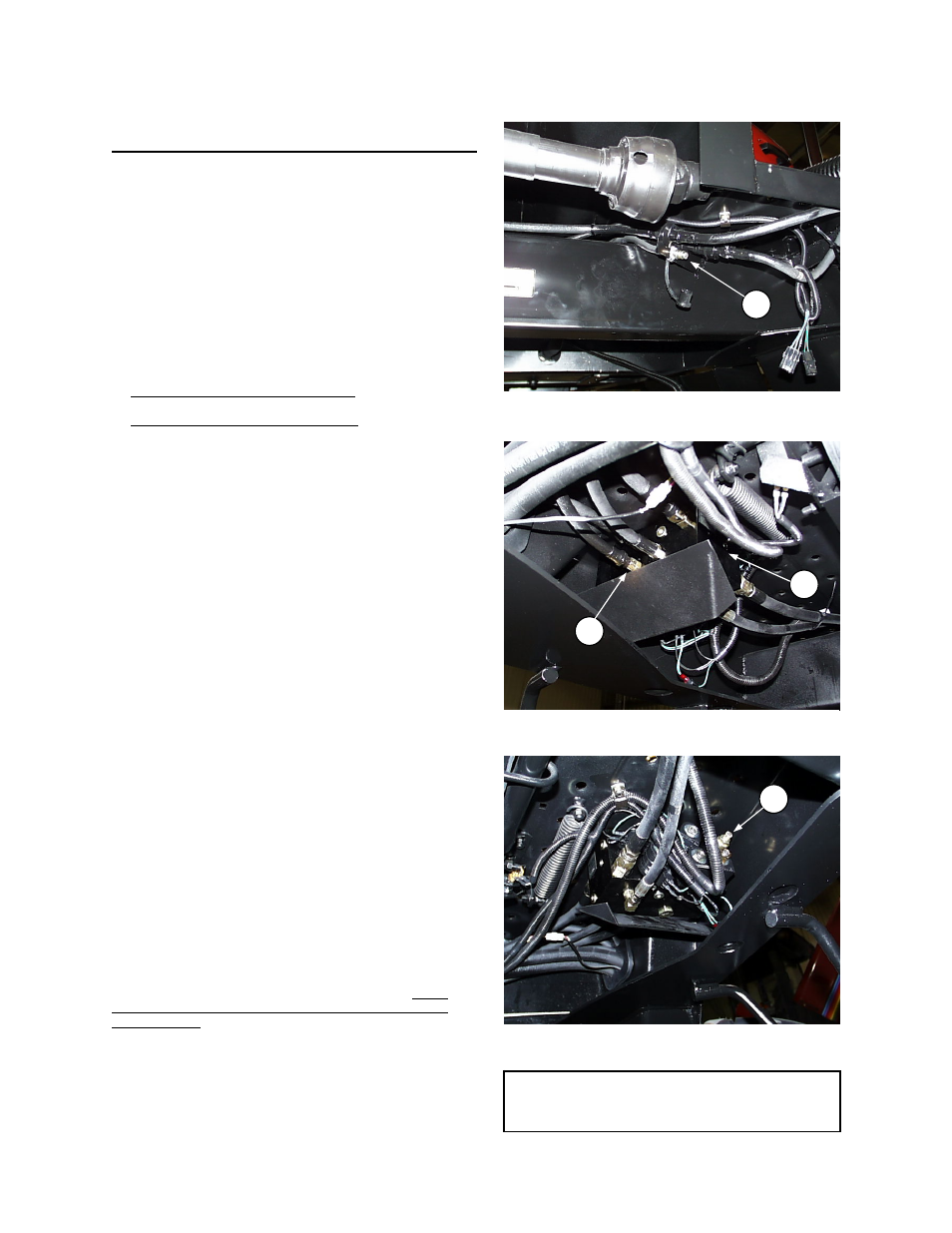

Control valve (A), located under the R/H tractor

floorboard, directs hydraulic flow to the header lift

cylinders, reel lift cylinders and the cylinder used to

engage the clutch for the sickle drive.

The control valve relief pressure is pre-set to be

sufficient for all header sizes and options. Should lift

capacity problems develop, check and adjust cylinder

control valve relief pressure as follows:

1. Lower header and reel fully, stop engine and remove

key from ignition.

2. The same relief valve protects both header and reel

lift circuits. It is most convenient to check relief

pressure in the reel lift circuit.

For tractors with reel lift hydraulics, reel lift quick

coupler (B) is located at left-hand leg.

For tractors without reel lift hydraulics, the header lift

circuit may be tapped at Port "C" of the lift valve.

Remove hose (C) to access port.

3. Attach a 3000 psi (20 MPa) pressure gauge to a

hose that is long enough to allow pressure to be

read from the operator's seat. Attach hose to quick

coupler or valve (see step 2) and position gauge to

be visible from the seat.

4. Start engine and position throttle lever fully back

(low idle). When oil is warm (minimum 100° F (38°

C)), activate the lift control for the circuit you have

tapped (reel or header) and check gauge pressure

reading.

5. Pressure should be 2400 to 2650psi (16.5 to 18.2

MPa)

If not, proceed with adjustment:

EXCEPTION: 36’ 972 Header requires 2500 psi

(17.2 MPa).

6. Lower header and reel fully. Stop engine and remove

key.

7. To adjust relief setting:

• Loosen jam nut at relief valve (D).

• Turn the adjustment screw in 1/4 turn increments,

clockwise to increase relief pressure, counter-

clockwise to decrease.

NOTE: 1/4 turn = approx. 80 psi change

8. Repeat checking and adjustment until relief pressure

is correct, then tighten nut at (D).

IMPORTANT: If relief pressure does not increase after

adjusting the screw two or three times, check relief valve

as follows: Remove relief valve (D) from control valve

block. Check that no contaminant is preventing the

spring-loaded poppet from properly seating against the

valve

body. Clean as required, and reinstall valve. Reset

adjustment screw to original position before checking

relief pressure.

B

REEL LIFT QUICK COUPLER

C

A

CYLINDER CONTROL VALVE (FRONT VIEW)

D

CYLINDER CONTROL VALVE (REAR VIEW)

NOTE: For hydraulic schematics, see

“SCHEMATICS” section at back of this

book.