Operation attaching the header – MacDon 9352c SP User Manual

Page 42

Form # 147459

Issue 11/06 Web Rev_01

40

OPERATION

Attaching the Header

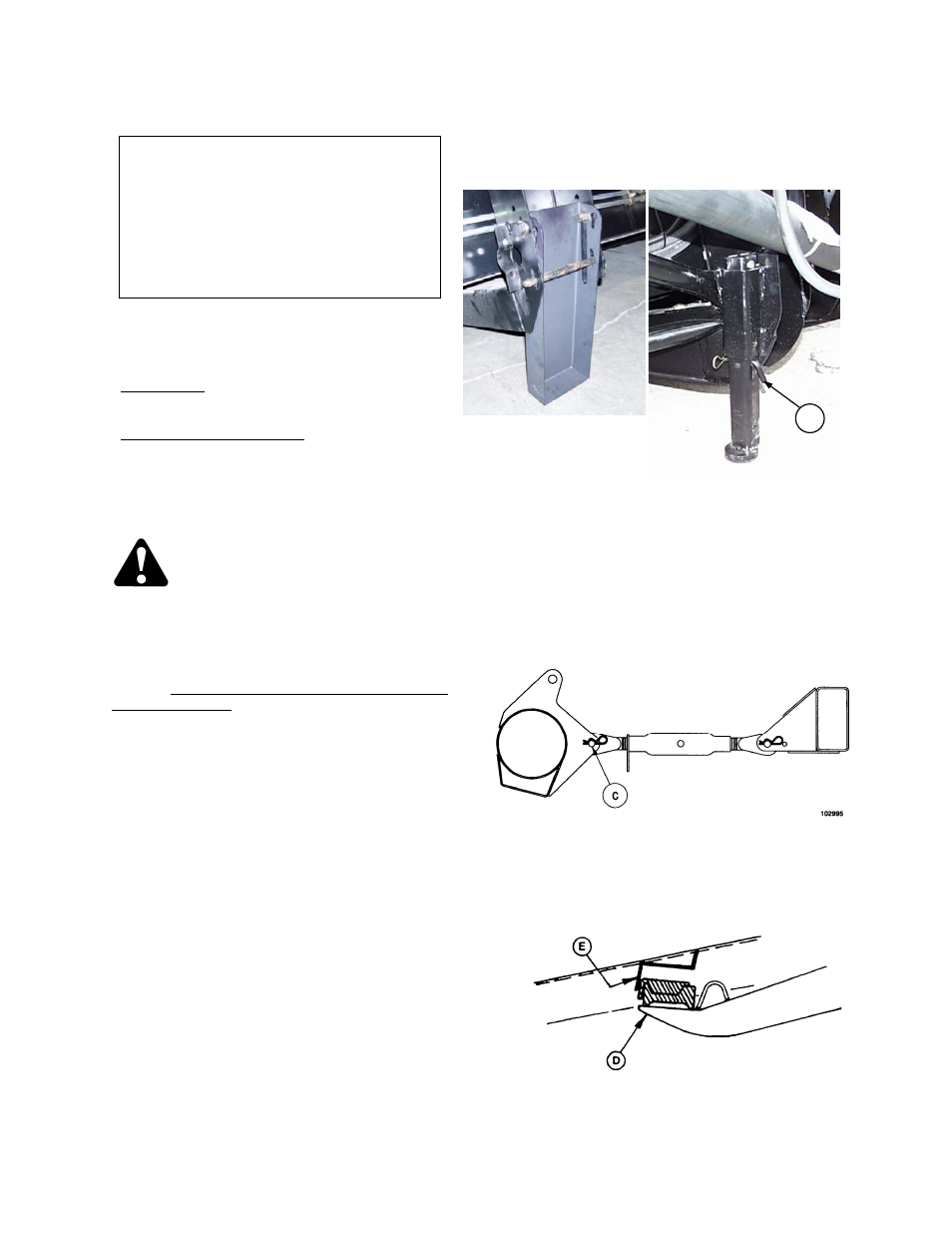

1. Choose an area that is as level as possible and

set header stand (A) in the down position.

942 Header, set 2 inch (50 mm) blocks under

each end of cutterbar.

960 & 970 Series Headers, be sure header and

tractor have been properly prepared for

windrower use.

See "Preparing Tractor and Headers" in

Assembly section for details.

CAUTION: Be sure area is clear of

bystanders, then start engine.

2. Fully retract header lift cylinders. For units with

Header Express Down option, use switch on

side console to bypass the feature.

NOTE: For 30’ & 36’ Harvest Headers with

Transport Option; when attaching to header in

transport mode, position 6 inch high (150 mm)

blocks for drive tires to provide adequate linkage

height. Blocks should be at least the width of the

drive tires and long enough that drive tires are fully

supported when attaching header.

3. Slowly drive tractor forward so that lift linkage

enters header legs. Continue to drive slowly

forward until linkage contacts support plate in

the lower header leg, and header nudges

forward. Place variable speed lever into neutral

position and lock steering wheel. Stop engine

and remove key.

4. Adjust length of center link and connect to

header at (C). For 962 and 972 headers, use

the lower, more rearward hole in mount on

header tube as shown.

NOTE: Ensure that thread length is equal at

both ends of center link. See "Header Angle for

adjustment details.

5. Check that bottom of linkage (D) is properly

engaged in header leg, contacting support plate

(E).

NOTE: For Harvest Headers with gauge

wheels, instructions under "Attaching" and

"Detaching the Header" which refer to the

"header stand" do not apply. Use the "stand"

position of the gauge wheels to support rear of

header. All gauge wheel positions are identified

on a decal located at each gauge wheel. Be

sure to reposition gauge wheel to field position

before operating.

INSTALL CENTER LINK

CHECK FOR PROPER ENGAGEMENT

A

HEADER STAND - DOWN POSITION

963 HEADER STAND