Maintenance/service greasing the windrower tractor, 10 hours 50 hours – MacDon 9352c SP User Manual

Page 63

Form # 147459

Issue 11/06 Web Rev_01

61

MAINTENANCE/SERVICE

Greasing the Windrower Tractor

See "Fuels, Fluids and Lubricants" for recom-

mended greases.

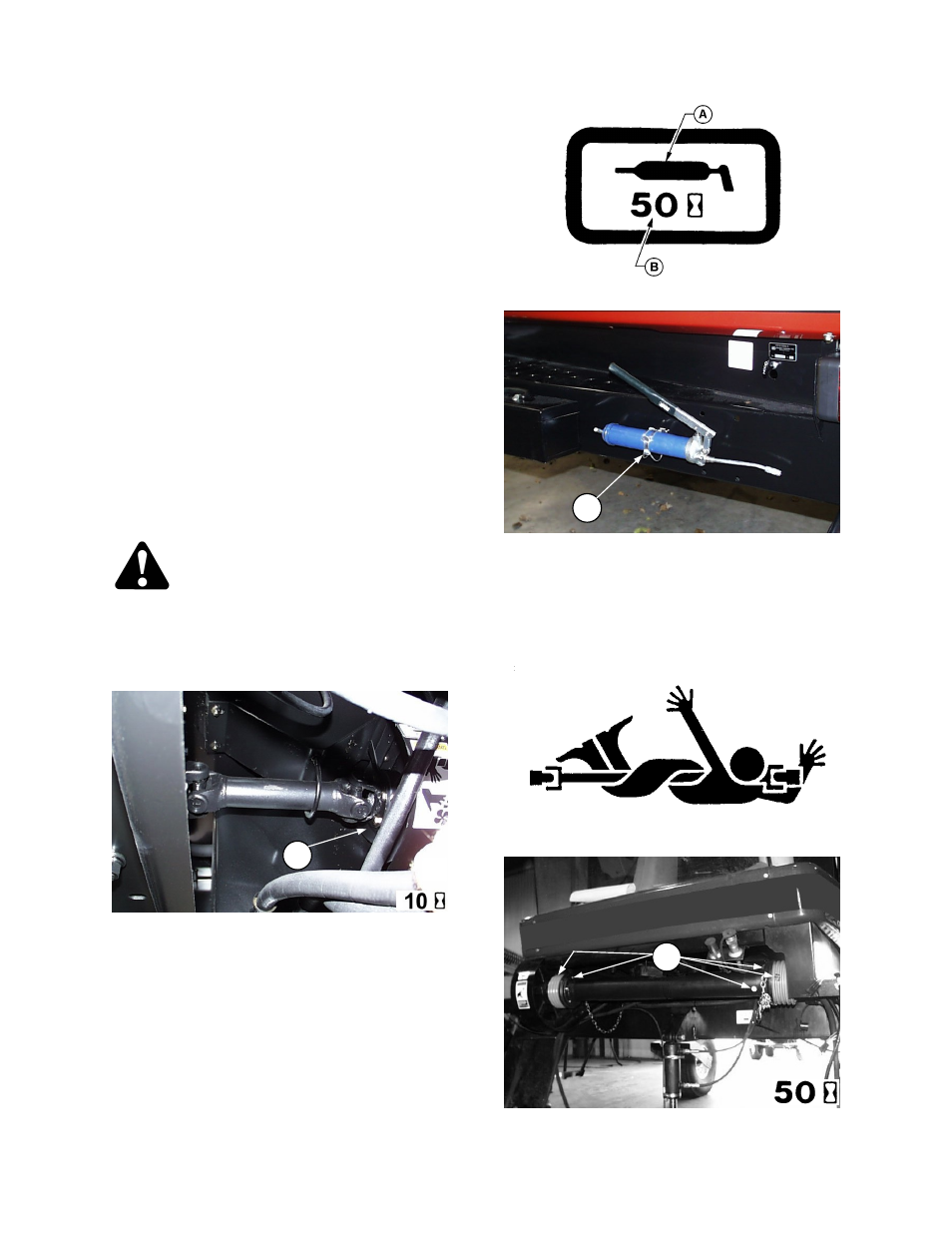

The following greasing points are marked on the

windrower by decals showing a grease gun (A),

and grease interval (B) in hours of operation. Use

the engine hour meter in the cab and the

"Maintenance Checklist" provided to keep a record

of scheduled maintenance.

Procedure:

1. Wipe grease fitting with a clean cloth before

greasing, to avoid injecting dirt and grit.

2. Inject grease through fitting with grease gun

until grease overflows. Inject grease slowly to

prevent seal damage.

3. Leave excess grease on fitting to keep out dirt.

4.

Replace any loose or broken fittings

immediately.

5. If fitting will not take grease, remove and clean

thoroughly. Also clean lubricant passageway.

Replace fitting if necessary.

6. Store grease gun on tractor frame at (C).

DANGER: Stay clear of drivelines

until all movement has stopped.

Entanglement with rotating driveline

will cause serious personal injury or death.

Avoid loose fitting or dangling clothing.

10 Hours

50 Hours

NOTE: For Harvest Header, there are two more 10

Hour fittings on driveline connector shaft.

STAY CLEAR OF ROTATING DRIVELINES

C

GREASE GUN STORAGE

SAMPLE GREASE DECAL

D

DRIVELINE (D) - FIVE FITTINGS

(2 CROSSES, 1 SHAFT, 2 SHIELD)

TRANSMISSION DRIVELINE SLIP JOINT (E) -

ONE

FITTING

E