Operator’s station – MacDon M150 SP User Manual

Page 51

OPERATOR’S STATION

Form 169017 / 169087 / 169095

49

Revision C

END

L1

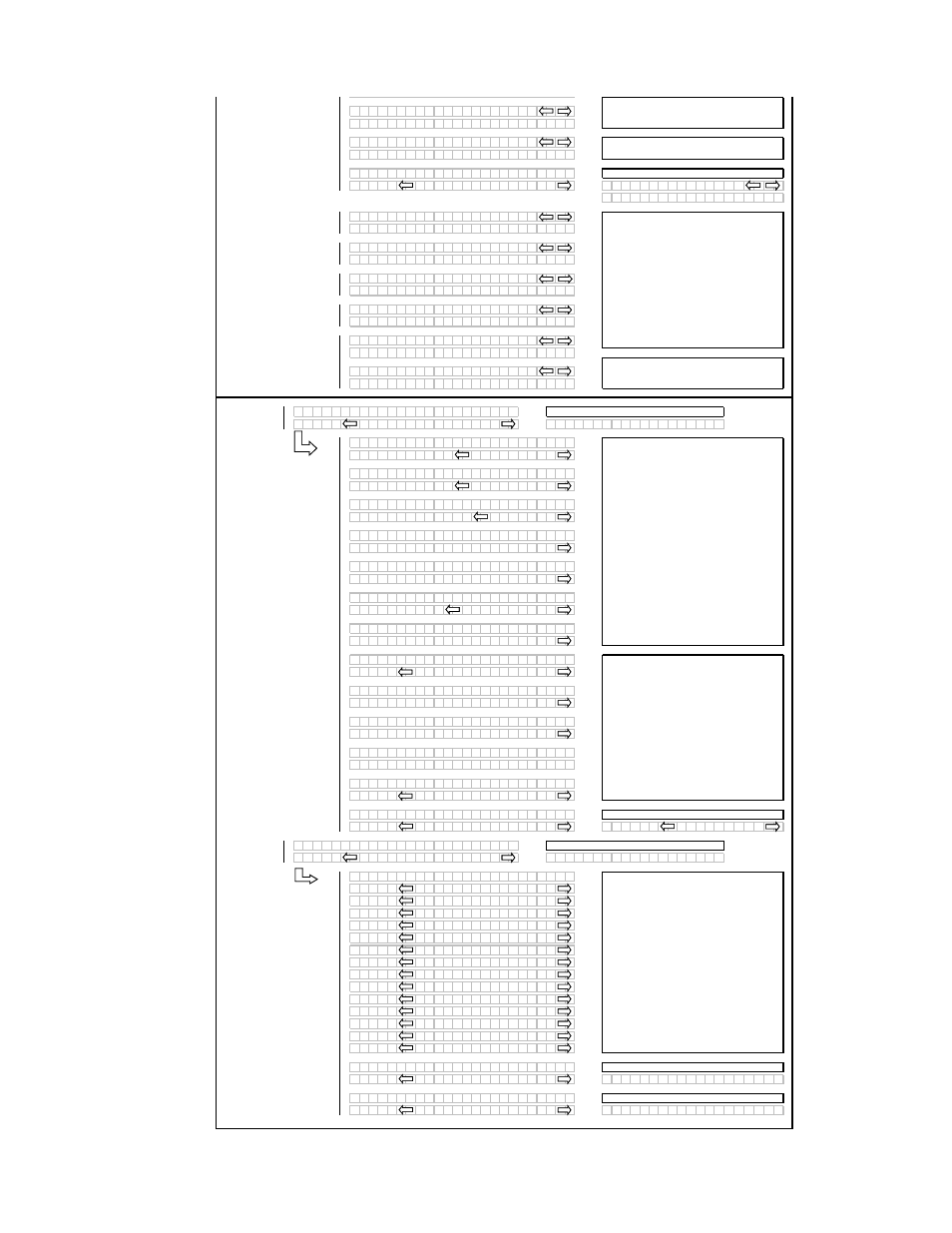

C x x x || S E N S O R

I N P U T

L2

M x x x || W H E E L

S P E E D

1 2 3

H Z

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || H Y D

O I L

T E M P

1 . 0 0

V

L1

C x x x || E X I T

R E A D

S E N S O R S ?

L2

M x x x ||

N O / Y E S

S E N S O R

I N P U T

H D R

H E I G H T

3 . 5 9

V

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || H D R

H E I G H T

S E N S O R

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || H D R

A N G L E

S E N S O R

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || 2 . 4 5

V

F L O A T

S E N S O R

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || K N I F E

S P E E D

S E N S O R

L1

C x x x || S E N S O R

I N P U T

L2

M x x x ||

R E E L

S P E E D

S E N S O R

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || H Y D

O I L

T E M P

S E N S O R

L1

C x x x || A C T I V A T E

F U N C T I O N S ?

L2

M x x x ||

N O / Y E S

F O R C E

H E A D E R

T Y P E ?

L1

C x x x || A C T I V A T E

F U N C T I O N S ?

L2

M x x x || H E A D E R

D O W N / U P

L1

C x x x || A C T I V A T E

F U N C T I O N S ?

L2

M x x x ||

R E E L

D O W N / U P

L1

C x x x || A C T I V A T E

F U N C T I O N S ?

L2

M x x x || H D R

T I L T

I N / O U T

L1

C x x x || A C T I V A T E

F U N C T I O N S ?

L2

M x x x || K N I F E

D R I V E

O N

L1

C x x x || A C T I V A T E

F U N C T I O N S ?

L2

M x x x || D R A P E R / A U G E R

O N

L1

C x x x || A C T I V A T E

F U N C T I O N S ?

L2

M x x x ||

R E E L

F O R E / A F T

L1

C x x x || A C T I V A T E

F U N C T I O N S ?

L2

M x x x ||

D W A

D R I V E

O N

L1

C x x x || A C T I V A T E

H Y D

P U R G E ?

L2

M x x x ||

N O / Y E S

L1

C x x x || T O

A C T I V A T E

P U R G E

L2

M x x x || P R E S S

A N D

H O L D

L1

C x x x || P U R G E

C Y C L E

S T A R T E D

L2

M x x x || P R E S S

A N D

H O L D

L1

C x x x || P U R G E

C Y C L E

E N D E D

L2

M x x x ||

L1

C x x x || P U R G E

C Y C L E

E N D E D

L2

M x x x ||

N O

E X I T

Y E S

L1

C x x x || E X I T

F U N C T I O N

M E N U ?

L2

M x x x ||

N O / Y E S

H E A D E R

D O W N / U P

L1

C x x x || F O R C E

H E A D E R

T Y P E ?

L2

M x x x ||

N O / Y E S

E X I T

D I A G N O S T I C S ?

L1

C x x x || S E L E C T

H E A D E R

T Y P E

L2

M x x x ||

D I S K

H E A D E R

L2

M x x x ||

S K

A U G E R

L2

M x x x ||

D K

A U G E R

L2

M x x x ||

G R A S S

S E E D

L2

M x x x ||

2 0

F T

S K

D R A P E R

L2

M x x x ||

2 5

F T

S K

D R A P E R

L2

M x x x ||

3 0

F T

S K

D R A P E R

W

L2

M x x x ||

3 5

F T

S K

D R A P E R

L2

M x x x ||

1 5

F T

D K

D R A P E R

L2

M x x x ||

2 0

F T

D K

D R A P E R

L2

M x x x ||

2 5

F T

D K

D R A P E R

L2

M x x x ||

3 0

F T

D K

D R A P E R

L2

M x x x ||

3 5

F T

D K

D R A P E R

L2

M x x x ||

4 0

F T

D K

D R A P E R

L1

C x x x || E X I T

H E A D E R

T Y P E ?

L2

M x x x ||

N O / Y E S

F O R C E

H E A D E R T Y P E ?

L1

C x x x || E X I T

D I A G N O S T I C S ?

L2

M x x x ||

N O / Y E S

D I A G N O S T I C M O D E ?

If "NO" then jump to:

If "NO" then jump to:

When "SELECT" is pressed the program goes

to the EXIT HEADER TYPE? menu selection.

This allows the operator to select or "force" a

header ID configuration if a "NO HEADER" ID

is being read by the control system. The

header type will revert back to "NO HEADER"

every time the ignition is cycled.

If "NO" then jump to:

If "NO" then jump to:

If a disk header is detected then the

nomeclature should read: DISC DRIVE instead

of KNIFE DRIVE.

If "NO" then jump to:

Pressing and holding the right hand "arrow"

button activates a predetermined timed purge

cycle. Releasing pressure on the switch or a

completed cycle (timed out) will jump to the

PURGE CYCLE ENDED menu selection.

ACTIVATE HYD PURGE - This is to allow the

operator to purge the air from a new or

changed pump system.

The DWA menu selection should only be

available if the DWA INSTALLED? is set to

YES.

For diagnostic purposes each header function

can be activated by using the "arrow" keys on

the CDM. When "SELECT" is pressed the

program will go to the next function that can be

activated.

PWM OPERATION: If the HAZARD switch is

pressed instead of the TURN SIGNAL switch

the GSL will operate the PWM valve (HAZARD

sw must be held) and the PWM value will reset

to zero when released.

If "NO" then jump to:

When "SELECT" is pressed the program goes

to the EXIT READ SENSORS? menu

NOTE: The oil temp. readout applies to the

M205 model with the Sensata oil temp. sensor.

If a sensor has been disabled "SENSOR" will

be flashing in the area where the input reading

would have been.

NOTE: The oil temp. readout applies to the

M205 model with the Sensata oil temp. sensor.