Danger – MacDon M150 SP User Manual

Page 203

MAINTENANCE AND SERVICING

Form 169017 / 169087 / 169095

201

Revision C

7.13 WHEELS AND TIRES

7.13.1 DRIVE WHEELS

7.13.1.1 Tire

Inflation

a. Visually check daily that tires have not lost

pressure. Under-inflation of drive tires can cause

sidewall cracks.

DANGER

To avoid severe personal injury or death

caused by machine runaway, shut off engine

and remove key before performing any of the

following checks and/or adjustments.

b. Measure tire pressure annually with a gauge.

c. Maintain the pressure as follows:

• Bar - 32 psi (221 kPa)

• Turf - 20 psi (138 kPa)

DANGER

• Never install a tube in a cracked wheel rim.

• Never weld a wheel rim.

• Make sure all the air is removed from a tire

before removing the tire from the rim.

• Never use force on an inflated or partially

inflated tire. Make sure the tire is correctly

seated before inflating to operating

pressure.

• Do not remove, install or make repairs to a

tire on a rim unless you have the proper

equipment and experience to perform the

job. Take the tire and rim to a qualified tire

repair shop.

• If the tire is not in correct position on the

rim, or if too full of air, the tire bead can

loosen on one side, causing air to leak at

high speed and with great force. An air

leak of this nature can thrust the tire in any

direction, endangering anyone in the area.

• Use a safety cage if available.

• Do not stand over tire. Use a clip-on chuck

and extension hose.

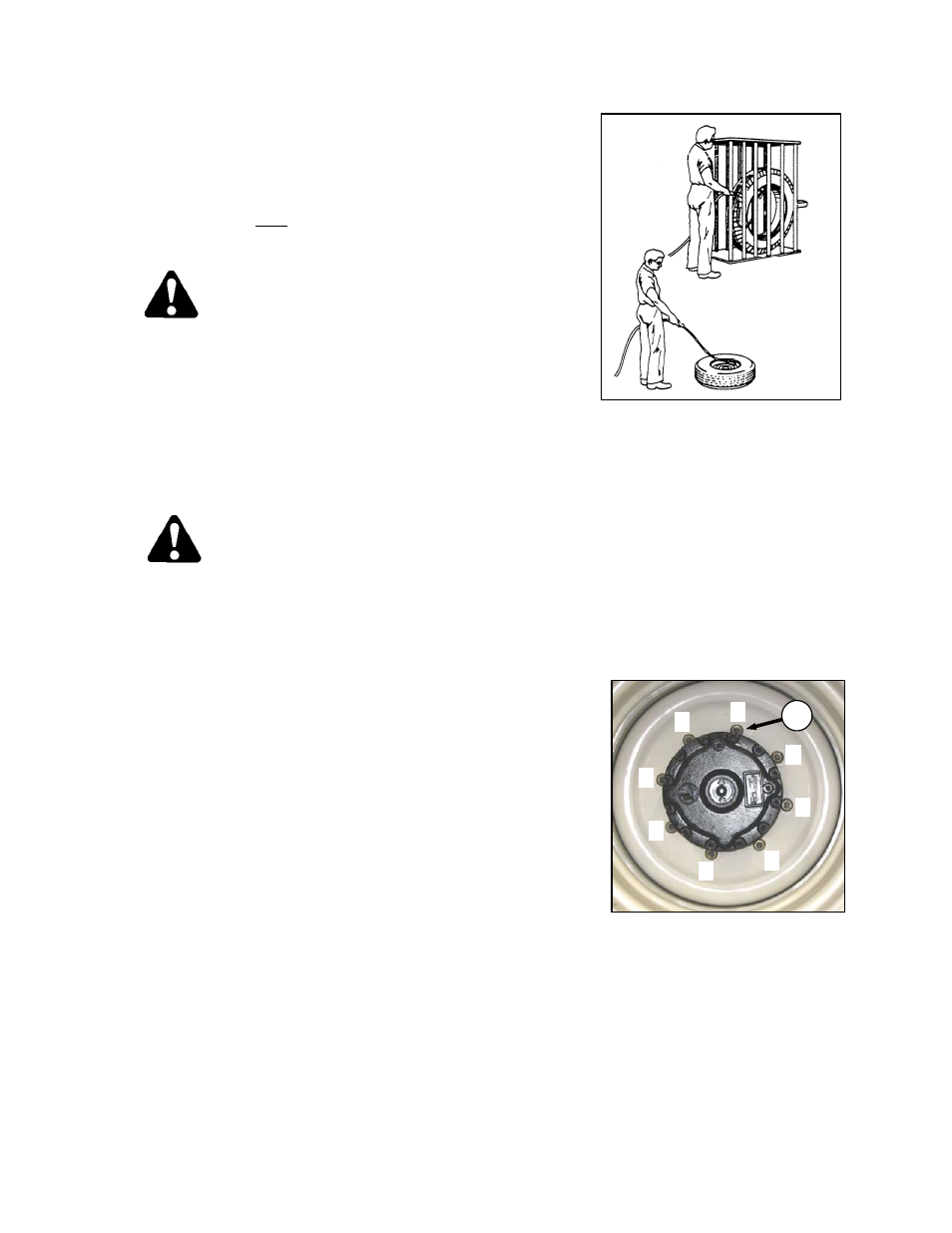

7.13.1.2 Wheel Nut Torque

At first use, or when a wheel is removed, check

drive wheel nut torque every 15 minutes on the

road, or one (1) hour in the field, until the specified

torque is maintained.

Continue with a checking schedule of ten (10),

and fifty (50) hours (field or road operation), and

then every 200 hour interval thereafter.

a. Tighten nuts (A) to 220 ft·lbf (300 N·m) using the

tightening sequence as shown.

NOTE

To avoid damage to wheel rims, do not

over-tighten wheel nuts.

b. Repeat sequence three times.

1

5

3

7

8

2

4

6

A