Danger – MacDon M150 SP User Manual

Page 113

HEADER OPERATION - R SERIES

Form 169017 / 169087 / 169095

111

Revision C

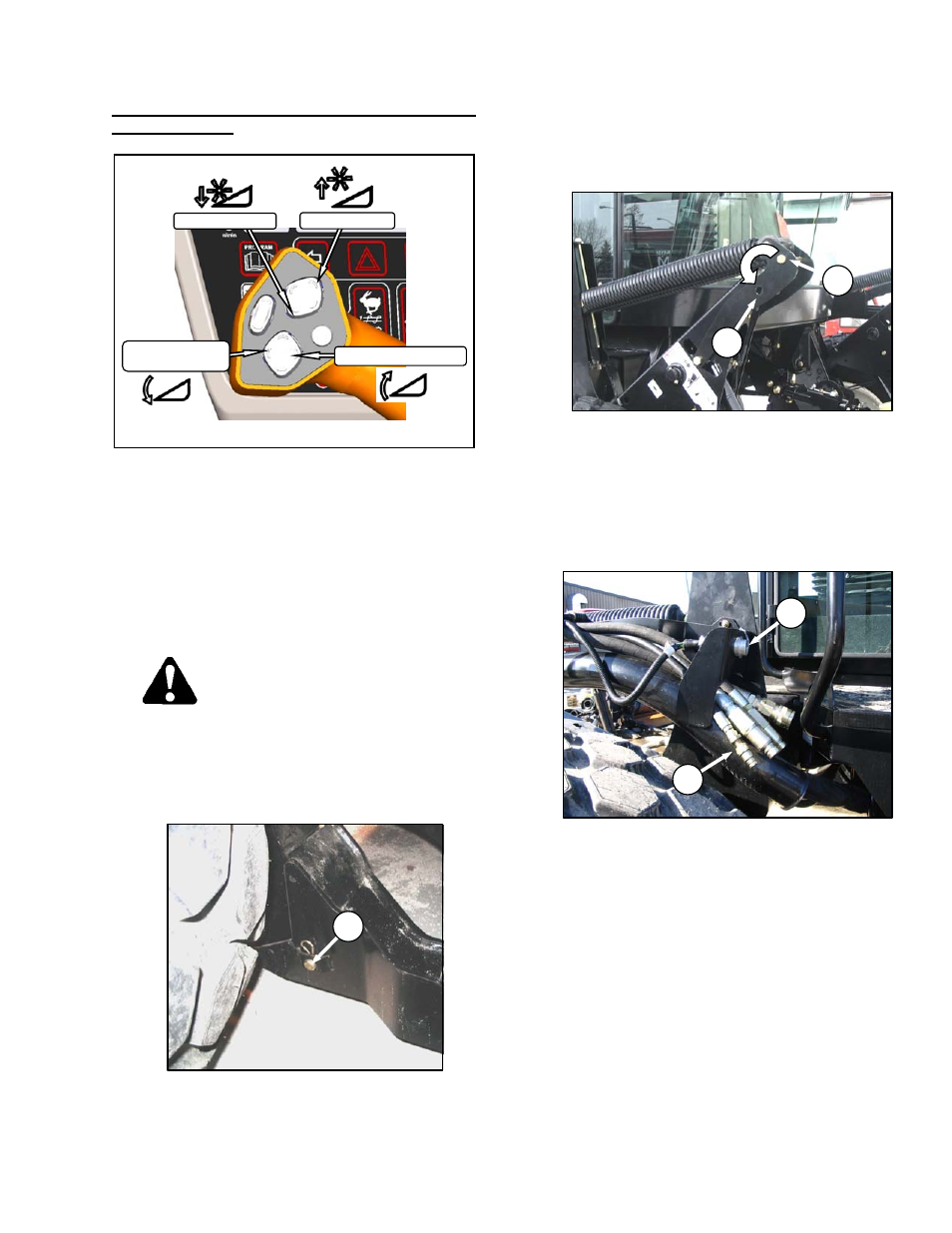

HYDRAULIC LINK WITH OPTIONAL SELF-

ALIGNMENT KIT

1. Adjust the position of the center-link cylinder

with the REEL UP and REEL DOWN

switches, and HEADER TILT switches on the

GSL to position the hook above the header

attachment pin.

2. Push the REEL DOWN switch to lower the

center-link onto the header until it locks into

position (handle is down).

e. Raise the header fully with the HEADER UP

switch on the GSL. Stop engine, and remove key.

DANGER

To avoid bodily injury from fall of raised

header, always engage header lift cylinder

stops when working on or around raised

header.

f.

Engage lift cylinder stops on both lift cylinders.

g. Install pin (A) through each boot and foot and

secure with hairpin.

IMPORTANT

Ensure pin (A) is fully inserted and hairpin is

installed behind bracket.

h. Remove pin (L) from storage position in linkage,

and insert in hole (M) to engage float springs.

Secure with hairpin.

i.

Disengage lift cylinder stops.

j.

Start engine, and activate HEADER DOWN switch

on GSL to lower header fully. Stop engine, and

remove key.

k. Connect header drive hydraulics (N) and electrical

harness (O) to header. Refer to the R80 Header

Operator’s Manual.

A

M

L

N

O

HEADER TILT UP

HEADER

TILT DOWN

REEL UP

REEL DOWN