Maintenance and servicing, 3 maintenance specifications, 1 recommended fuel, fluids and lubricants – MacDon M150 SP User Manual

Page 119

MAINTENANCE AND SERVICING

Form 169017 / 169087 / 169095

117

Revision C

7.3 MAINTENANCE

SPECIFICATIONS

7.3.1 RECOMMENDED FUEL, FLUIDS AND

LUBRICANTS

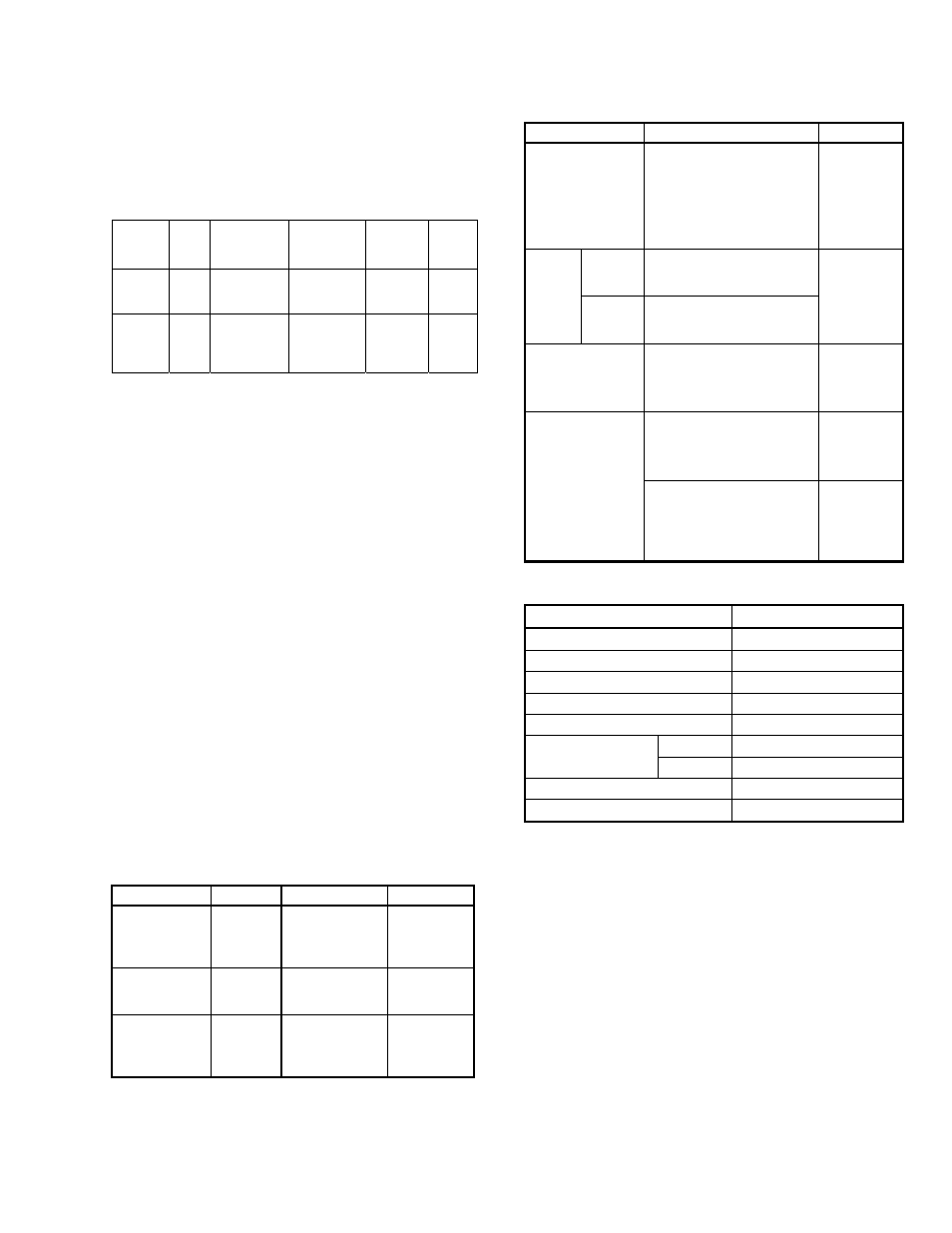

7.3.1.1 Fuel

FUEL SPEC SULPHUR

(by weight)

WATER &

SEDIMENT

(by vol.)

CETANE

NO.

°C

LUBRI

CITY

Diesel

Grade

No.2

ASTM

D-975

0.5% Max.

0.05% Max.

40 Min.

520

microns

Diesel

Grade

No.1 &

2 mix *

n/a

1% Max.

0.5% Max.

Preferred

0.1% Max.

45 - 55

Cold

Weather/

High Alt.

460

microns

* Optional when operating temp below 32

°F (0°C).

In extreme situations, when available fuels are of

poor quality or problems exist which are peculiar

to certain operations, additives can be used.

However, the engine manufacturer recommends

consultation with the fuel supplier or engine

manufacturer prior to use of fuel additives.

Among the situations where additives can prove

useful are the following:

• A cetane improver additive can be used with

low cetane fuels.

• A wax crystal modifier can help with fuels with

high cold filter plugging points (CFPP).

• An anti-icer can help prevent ice formation in

wet fuel during cold weather.

• An anti-oxidant or storage stability additive

can help with fuel system deposits and poor

storage stability.

• A lubricity enhancer can be used to increase

the lubricity of fuels so that they meet the

requirements given in the table above.

Diesel fuel conditioner is available from your

Dealer.

7.3.1.2 Fluids

FLUID SPEC

DESCRIPTION

USE

Antifreeze

ASTM

D-4985

Ethylene Glycol

With SCA

Equal Parts

With Water*

Engine

Coolant

Air

Conditioning

Refrigerant

R134A Refrigerant

Cab Air

Conditioning

System

Air

Conditioning

Compressor

Oil

SP-15 Compressor

Oil

Cab Air

Conditioning

Compressor

Lubricant

* High quality, soft, de-ionized or distilled water as

recommended by supplier.

7.3.1.3 Lubricants

LUBRICANT

SPEC / DESCRIPTION

USE

Grease

SAE Multi-Purpose

High Temp. Extreme

Pressure (EP2)

Performance With 1% Max

Molybdenum Disulphide

(NLGI Grade 2) Lithium

Base

As Required

Unless

Otherwise

Specified.

Engine

Oil

Cummins

SAE 15W40 Compliant With

SAE Specs For API Class

SJ And CH-4 Engine Oil

Engine

Crankcase.

CAT

SAE 15W40 Compliant With

SAE Specs For API Class

CH-4 and CI-4 Engine Oil

Hydraulic Oil

SAE 15W40 Compliant With

SAE Specs For API Class

SJ And CH-4 Engine Oil

Windrower

Drive.

Header

Drive.

Gear Lubricant

SAE 85W-140

API Service Class GL-5

Extreme Pressure Gear

Lubricant

Drive Wheel

Gears

Before Initial

Change.

SAE 75W-90

API Service Class GL-5

Fully Synthetic Gear

Lubricant

(SAE J2360 Preferred)

Gearbox.

Drive Wheel

Gears

After Initial

Change.

7.3.1.4 Capacities

ITEM CAPACITY

Fuel Tank

97 U.S. Gallons (378 liters)

Hydraulic Reservoir

17.2 U.S. Gallons (66 liters)

Gear Box

2.2 U.S. Quarts (2.1 liters)

Drive Wheel

1.5 U.S. Quarts (1.4 liters)

Engine Cooling System

5.3 U.S. Gallons (20 liters)

Engine Crankcase

Cummins

10.6 U.S. Quarts (10 liters)

CAT

15.8 U.S. Quarts (15 liters)

Air Cond. Refrigerant

3.6 lb (1.63 kg)

Air Cond. Compressor Oil

8.1 fl. oz. (240 cc)

7.3.1.5 Storage

Your machine can operate at top efficiency only if

clean fuel and lubricants are used.

• Use clean containers to handle all fuels and

lubricants.

• Store in an area protected from dust,

moisture, and other contaminants.

• Buy good quality, clean fuel from a reputable

dealer.

• Avoid storing fuel over long periods of time. If

you have a slow turnover of fuel in windrower

tank or supply tank, add fuel conditioner to

avoid condensation problems.

• Store fuel in a convenient place away from

buildings.