Operator’s station, Continued next page) – MacDon M150 SP User Manual

Page 50

OPERATOR’S STATION

Form 169017 / 169087 / 169095

48

Revision C

(continued next page)

L2

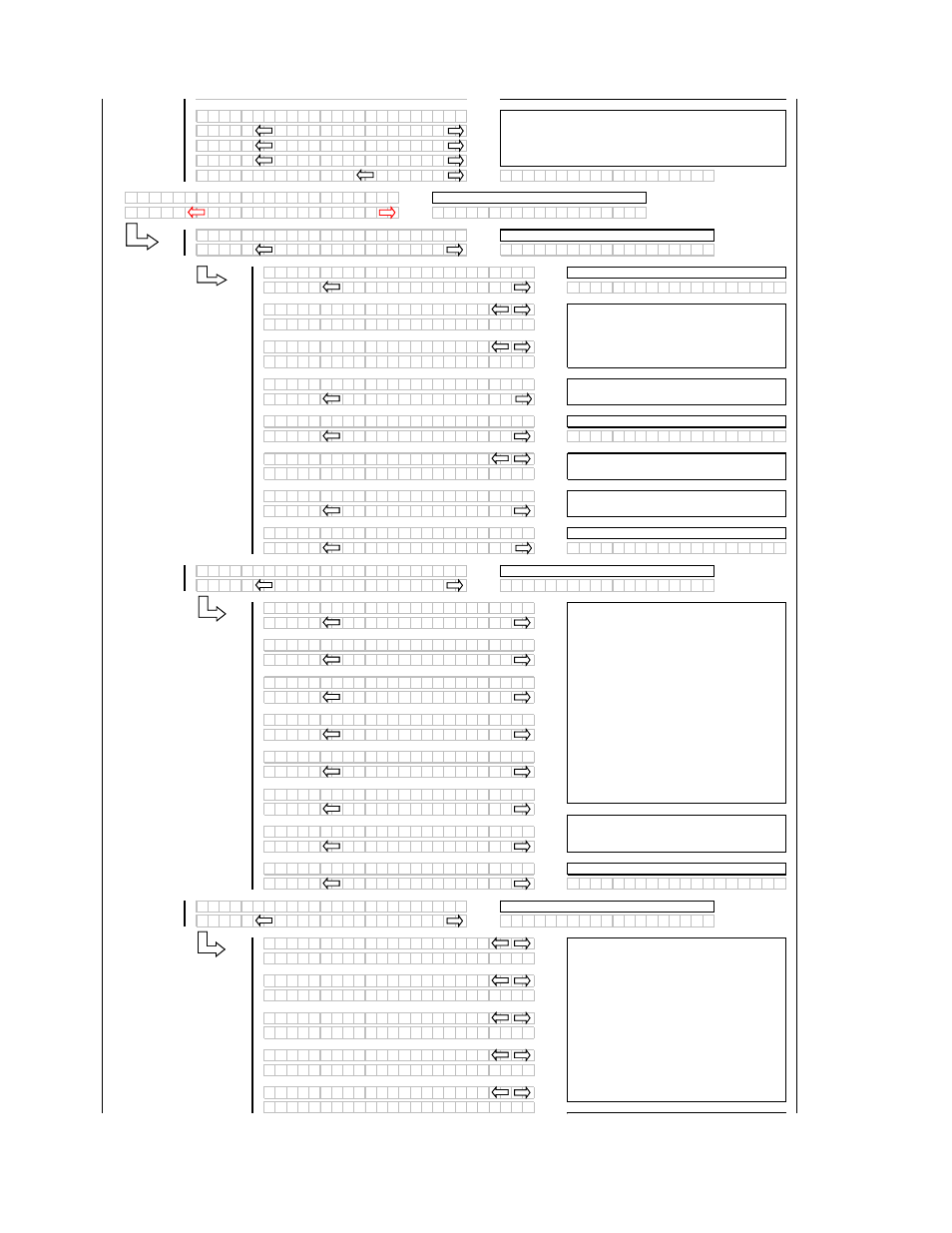

C x x x || T O

C A L I B R A T E

S E L E C T

L2

M x x x || H E A D E R H E I G H T

L2

M x x x || H E A D E R T I L T

L1

M x x x || H E A D E R F L O A T

L2

M x x x || E X I T C A L ? N O / Y E S

T O

C A L I B R A T E

S E L E C T

L1

C x x x

||

D I A G N O S T I C M O D E ?

L2

M x x x

||

N O

/ Y E S

T R A C T O R

S E T U P ?

L1

C x x x || V I E W E R R O R C O D E S ?

L2

M x x x ||

N O / Y E S

E N T E R

S E N S O R

S E T U P ?

L1

C x x x || V I E W T R A C T O R

C O D E S ?

||

L2

M x x x ||

N O / Y E S

V I E W

E N G I N E C O D E S ?

L1

1 || 1 2 3 4 . 5

H R S

1 2 3

||

L2

E

4 7 || S E N S O R

V O L T S

L O W

L1

2 || 1 2 3 0 . 5

H R S

1 2 3

||

L2

E

7 1 || L O W H Y D R A U L I C

O I L

L1

C x x x || E X I T T R A C T O R

C O D E S ?

L2

M x x x ||

N O / Y E S

L1

C x x x || V I E W E N G I N E

C O D E S ?

L2

M x x x ||

N O / Y E S

E N T E R

S E N S O R S E T U P ?

L1

1 || 1 2 3 4 . 5

H R S

1 2 3

||

L2

4 4 9 || F U E L P R E S S U R E

H I G H

L1

C x x x || E X I T E N G I N E

C O D E S ?

L2

M x x x ||

N O / Y E S

L1

C x x x || E X I T E R R O R

C O D E S ?

L2

M x x x ||

N O / Y E S

V I E W

T R A C T O R C O D E S ?

L1

C x x x || E N T E R S E N S O R

S E T U P ?

L2

M x x x || N O

/ Y E S

R E A D

S E N S O R

I N P U T S ?

L1

C x x x || K N I F E S P E E D

S E N S O R

L2

M x x x || E N A B L E / D I S A B L E

L1

C x x x || R E E L S P E E D

S E N S O R

L2

M x x x || E N A B L E / D I S A B L E

L1

C x x x || H E A D E R

H T

S E N S O R

L2

M x x x || E N A B L E / D I S A B L E

L1

C x x x || H E A D E R

T I L T

S E N S O R

L2

M x x x || E N A B L E / D I S A B L E

L1

C x x x || H E A D E R

F L O A T

S E N S O R

L2

M x x x || E N A B L E / D I S A B L E

L1

C x x x || O V E R L O A D

P R E S S U R E

L2

M x x x || E N A B L E / D I S A B L E

L1

C x x x || H Y D O I L

T E M P

S E N S O R

L2

M x x x || E N A B L E / D I S A B L E

L1

C x x x || E X I T S E N S O R

S E T U P ?

L2

M x x x ||

N O / Y E S

K N I F E

S P E E D

S E N S O R

L1

C x x x || R E A D S E N S O R I N P U T S ?

L2

M x x x || N O

/ Y E S

A C T I V A T E

F U N C T I O N S ?

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || H D R H E I G H T

3 . 5 9

V

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || H D R A N G L E

1 . 8 4

V

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || 2 . 4 5 V

F L O A T

2 . 8 4

V

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || K N I F E S P E E D

1 2 3

H Z

L1

C x x x || S E N S O R

I N P U T

L2

M x x x || R E E L S P E E D

1 2 3

H Z

If "NO" then jump to:

If "NO" then jump to:

The last 10 distinct error codes are stored.

The operator can select each sensor and

selectively enable or disable the sensor. This

can be used to disable a failed sensor to

eliminate false or erratic display readings.

If "NO" then jump to:

Select any of the sensors by using the turn signal switches to

cycle through the choices. Pressing SELECT will take the

operator to the calibration menu for that particular sensor. NO

is the default for EXIT CAL?. If "NO" then jump to:

If "NO" then jump to:

If "NO" then jump to:

If "NO" then jump to:

The last 10 distinct error codes are stored

along with the code #, Exxx, engine hours and

number of occurrences. The "arrow" keys are

used to cycle between codes.

If "NO" then jump to the first error code logged.

If "NO" then jump to the first engine error code

logged.

For diagnostic purposes each sensors input

signal can be read. This helps in determining

how each sensor is operating and if the proper

output voltages are being received by the

control system.

If "NO" then jump to:

If "NO" then jump to:

When "SELECT" is pressed the program goes

to the EXIT SENSOR SETUP? menu

selection.

NOTE: The oil temp. readout applies to the

M205 model with the Sensata oil temp. sensor.