Troubleshooting and diagnostics – Lenze ESV SMV frequency inverter User Manual

Page 62

60

Lenze SMVector 13465100 EDBSV01 EN v18

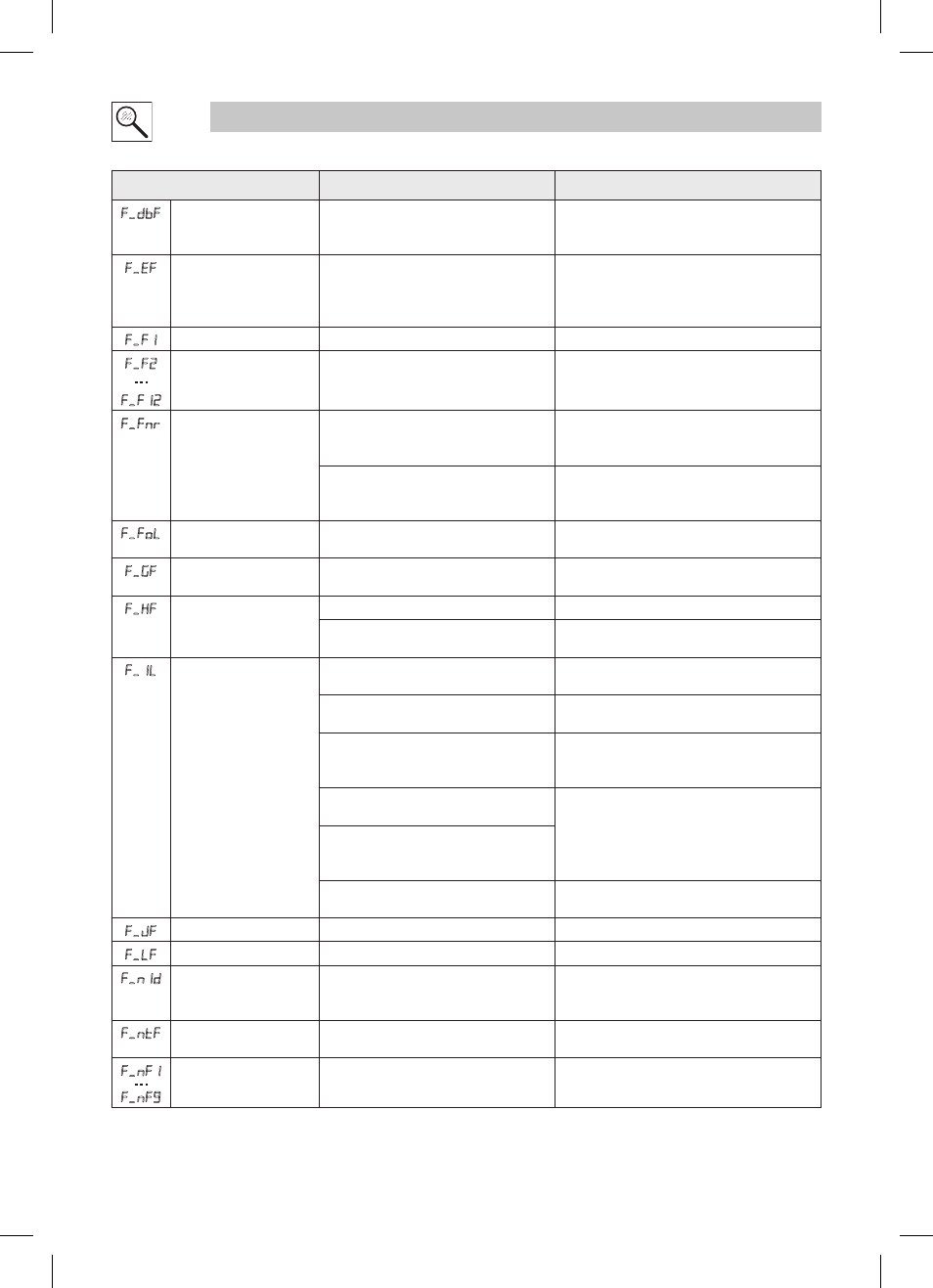

Troubleshooting and Diagnostics

Fault

Cause

Remedy

(1)

f.dbF

Dynamic Braking fault

Dynamic braking resistors are overheating • Increase active decel time

(P105, P126, P127).

• Check mains voltage and P107

f.EF

External fault

• P121…P124 = 21 and that digital input

has been opened.

• P121…P124 = 22 and that digital input

has been closed.

• Correct the external fault condition

• Make sure digital input is set properly for NC

or NO circuit

f.F1

EPM fault

EPM missing or defective

Power down and replace EPM

f.F2

…

f.F12

Internal faults

Contact factory technical support

f.Fnr

Control Configuration Fault The drive is setup for REMOTE KEYPAD

control (P100=2 or 5) but is not setup to

communicate with a remote keypad

Set P400 = 1, or P600 = 1

The drive is setup for NETWORK ONLY

control (P100=3) but is not setup for

network communications

Set P400 or P600 to a valid network

communications protocol selection

f.FoL

TB25 (4-20 mA signal)

Threshold fault

4-20 mA signal (at TB-25) drops below the

value set in P164.

• Check signal/signal wire

• Refer to parameters P163 and P164.

f.GF

OEM Defaults data fault

Drive is powered up with P199 =1 and

OEM settings in the EPM are not valid.

Install an EPM containing valid OEM Defaults

data or change P199 to 0.

f.HF

High DC Bus Voltage fault

Mains voltage is too high

Check mains voltage and P107

Decel time is too short, or too much regen

from motor

Increase active decel time (P105, P126, P127)

or install Dynamic Braking option

f.1L

Digital Input

Configuration fault (P121...

P124)

More than one digital input set for the same

function

Each setting can only be used once (except

settings 0 and 3)

Only one digital input configured for MOP

function (Up, Down)

One input must be set to MOP Up, another must

be set to MOP Down

PID mode is entered with setpoint

reference and feedback source set to the

same analog signal

Change PID setpoint reference (P121…P124) or

feedback source (P201).

One of the digital inputs (P121…P124) is

set to 10 and another is set to 11…14.

Reconfigure digital inputs

One of the digital inputs (P121…P124)

is set to 11 or 12 and another is set to

13 or 14.

PID enabled in Vector Torque mode (P200

= 1 or 2 and P300 = 5)

PID cannot be used in Vector Torque mode

f.JF

Remote keypad fault

Remote keypad disconnected

Check remote keypad connections

f.LF

Low DC Bus Voltage fault Mains voltage too low

Check mains voltage

f.n1d

No Motor ID fault

An attempt was made to start the drive

in Vector or Enhanced V/Hz mode prior to

performing the Motor Auto-calibration

Refer to parameters P300…P399 for Drive Mode

setup and calibration.

f.ntF

Module communication

fault

Communication failure between drive and

Network Module.

Check module connections

f.nF1

…

f.nF9

Network Faults

Refer to the module documentation. for

Causes and Remedies.