Commissioning – Lenze ESV SMV frequency inverter User Manual

Page 44

42

Lenze SMVector 13465100 EDBSV01 EN v18

Commissioning

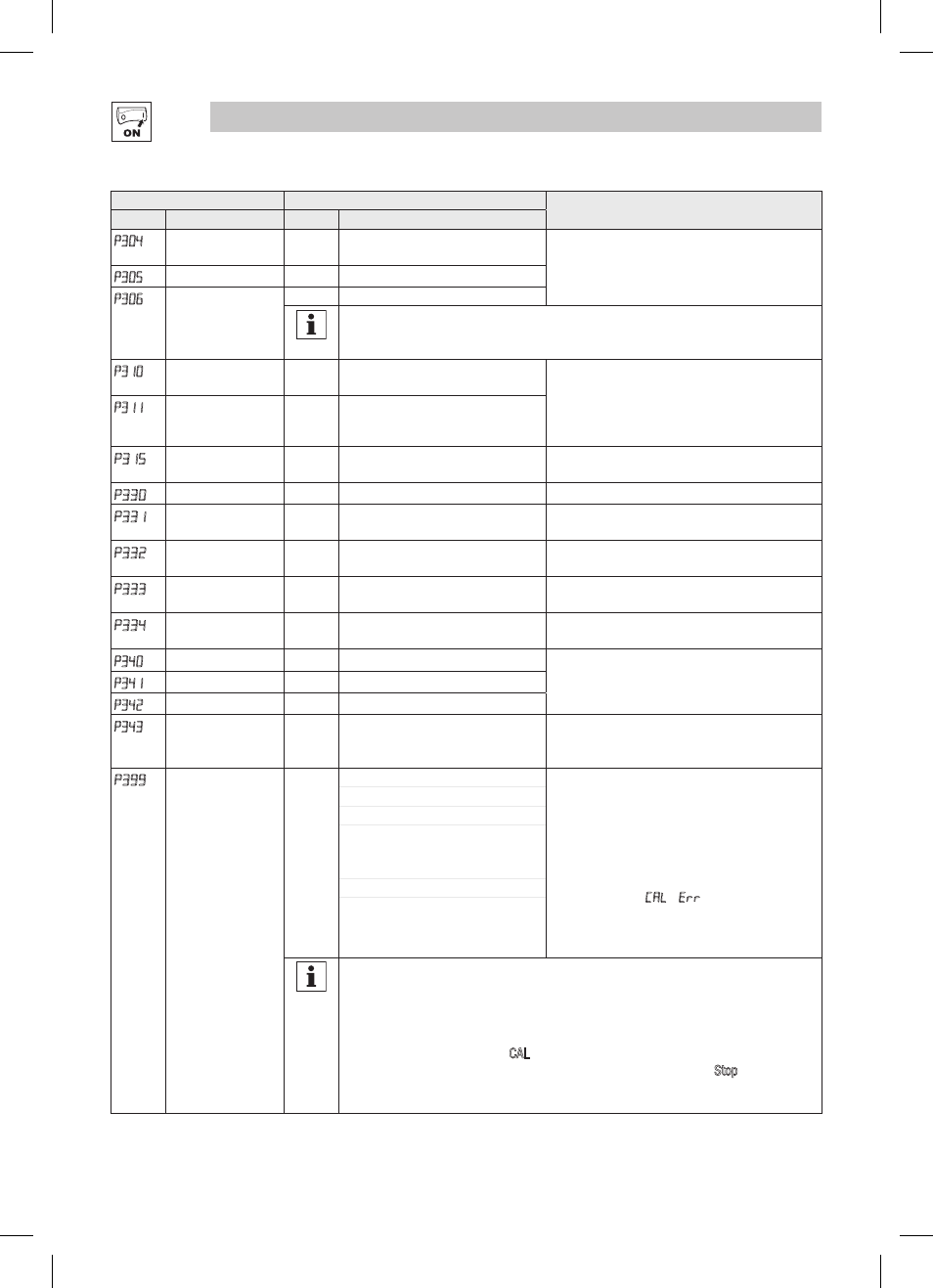

Code

Possible Settings

IMPORTANT

No.

Name

Default Selection

p304

(1)

Motor Rated

Frequency

60

0

{Hz} 1000

Set to motor nameplate data

P305

(1)

Motor Rated Speed

1750

300

{RPM} 65000

P306

(1)

Motor Cosine Phi

0.80

0.40 0.99

NOTE If motor cosine phi is not known, use one of the following formulas:

cos phi = motor Watts / (motor efficiency X P302 X P303 X 1.732)

cos phi = cos [ sin

-1

(magnetizing current / motor current) ]

P310

(1)

Motor Stator

Resistance

0.00 {

W} 64.00

• P310, 311 default setting depends on drive rating

• Will be automatically programmed by P399

• Changing these settings can adversely affect

performance. Contact factory technical support

prior to changing

p311

(1)

Motor Stator

Inductance

0.0

{mH} 2000

P315

Dead Time

Compensation Factor

0.0

-50.0 {%} +50.0

• Adjust dead time correction from internal default

• Takes effect when P399 = 3.

P330

Torque Limit

100

0

{%} 400

When P300 = 5, sets the maximum output torque.

P331

Preset Torque

Setpoint #1

100

0

{%} 400

TB-13A activated; P121 = 3 and P300 = 5

P332

Preset Torque

Setpoint #2

100

0

{%} 400

TB-13B activated; P122 = 3 and P300 = 5

P333

Preset Torque

Setpoint #3

100

0

{%} 400

TB-13C activated; P123 = 3 and P300 = 5

P334

(2)

Preset Torque

Setpoint #4

100

0

{%} 400

TB-13D activated; P124 = 3 and P300 = 5

P340

(1)

Current Loop P Gain

0.25

0.00 16.0

Changing these settings can adversely affect

performance. Contact factory technical support

prior to changing.

P341

(1)

Current Loop I Gain

65

12

{ms} 9990

P342

(1)

Speed Loop Adjust

0.0

0.0

{%} 20.0

P343

Slip Compensation

Response Filter

99

90

{ms} 9999

Low pass filter time constant for varying the slip

compensation response to changes in the motor

current.

P399

Motor Auto-

calibration

0

0 Calibration Not Done

• If P300 = 4 or 5, motor calibration must be

performed if P399 is not set to 3 (bypass

calibration).

• If P300=2 or 3, motor calibration is

recommended.

• Use option 2 if option 1 failed or in case of non-

standard motors

• An alternating CAL / Err will occur if:

- attempt motor calibration with P300 = 0 or 1

- motor calibration is attempted before

programming motor data

1 Standard Calibration Enabled

2 Advanced Calibration Enabled

3 Bypass Calibration, enable

operation in vector mode w/o Auto

Calibration

4 Standard Calibration Complete

5 Advanced Calibration Complete

NOTE: To run the Auto Calibration:

− Set P302...P306 according to motor nameplate

− Set P399 = 1 or 2 (if option 1 failed or in case of non-standard motor)

− Make sure motor is cold (20° - 25° C)

− Apply a Start command

− Display will indicate CAL for about 40 seconds

− Once the calibration is complete, the display will indicate Stop; apply another

Start command to actually start the motor

− Parameter P399 will now be set to 4 or 5.

(1)

Any changes to this parameter will not take effect until the drive is stopped.

(2)

Parameter applicable to SMV models 15HP (11kW) and higher.