INFICON SQM-242 Thin Film Deposition Controller Card Operating Manual User Manual

Page 62

7 - 8

IP

N 07

4-

54

9-

P1

A

SQM-242 Operating Manual

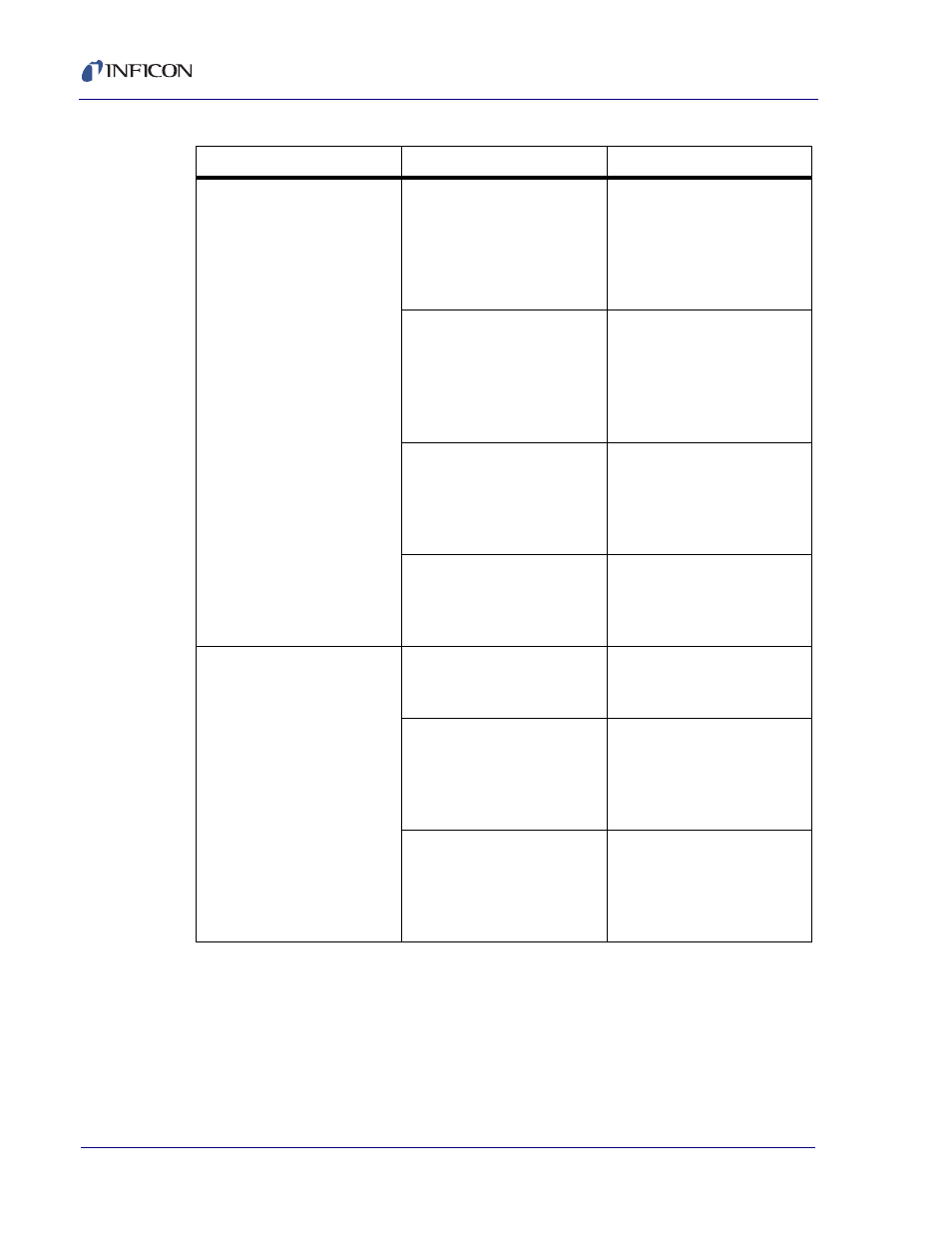

6. Poor thickness

reproducibility.

a. Variable source flux

distribution.

a. Move sensor to a more

central location to reliably

sample evaporant, ensure

constant relative pool height

of melt, avoid tunneling into

the melt.

b. Sweep, dither, or position

where the electron beam

strikes the melt has been

changed since the last

deposition.

b. Maintain consistent source

distribution by maintaining

consistent sweep

frequencies, sweep

amplitude and electron beam

position settings.

c. Material does not adhere

to the crystal.

c. Make certain the crystal

surface is clean; avoid

touching crystal with fingers,

make use of an intermediate

adhesion layer.

d. Cyclic change in rate.

d. Make certain source's

sweep frequency is not

"beating" with the SQM-242

measurement frequency.

7. Large drift in thickness

(greater than 200 Å for a

density of 5.00 g/cc) after

termination of sputtering.

a. Crystal heating due to poor

thermal contact.

a. Clean or polish the crystal

seating surface on the crystal

holder.

b.External magnetic field

interfering with the sensor's

magnetic field (sputtering

sensor.)

b.Rotate sensor magnet to

proper orientation with

external magnetic field, refer

to the sputtering sensor

manual IPN 074-157.

c. Sensor magnet cracked or

demagnetized (sputtering

sensor.)

c. Check sensor magnetic

field strength, the maximum

field at the center of the

aperture should be 700

gauss or greater.

Table 7-2 Troubleshooting Sensors

SYMPTOM

CAUSE

REMEDY