Video balancer – COATS Series XR 1800 Balancer User Manual

Page 37

Important: Always read and follow the on-screen operating instructions.

• 31

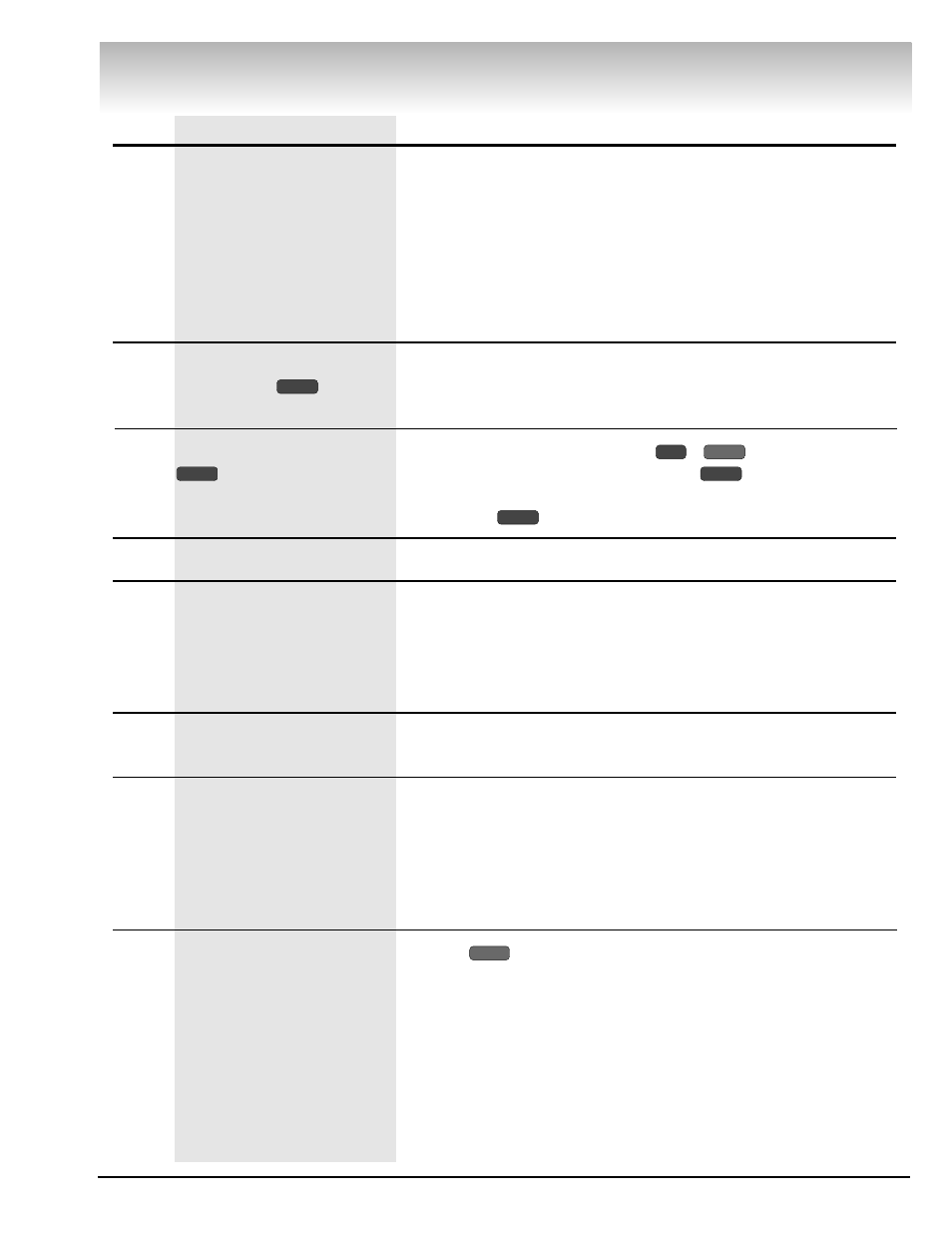

Video Balancer

Error

Err. 3

Err. 4

Err. 5

Err. 6

Err. 7 /

Err. 8

Err. 9

Err. 11

Err. 12

Symptom

Calculation Error.

Incorrect Machine Self-

Calibration.

Counterclockwise rotation.

After pushing

the wheel

turns in the opposite direction.

Wheel guard hood open or the

button has been pushed

without closing the wheel

guard hood.

Ram Error or defect.

Reading error of NOVRAM

parameters.

Access error in NOVRAM

parameters writing.

High speed error.

During rotation to measure the

unbalance value, the wheel

speed has gone over 270 r.p.m.

Error in the unbalance measur-

ing cycle.

START

START

Check

1. Check the wheel dimensions setting.

2. Check the piezo pick-ups connections - electrical & mechanical. (in

MACHINE SELF-TEST, push on spindle shaft and verify that both

piezo outputs change.

3. Execute the 4-ounce weight (machine self-calibration).

4. Mount a wheel having a known unbalance (lower than 4.00 ounces

or 100 grams) and check the balancer reading.

5. Replace the PC board.

1. In MACHINE SELF-TEST - check the operation of UP/DOWN - RESET

signals of the encoder.

2. Check the connection of the motor for rotation.

1. Reset the error by pushing button

=

.

2. Close the wheel guard hood and press

button.

3. Check operation of the wheel guard micro-switch.

4. Press the

button.

1. Reset NOVRAM & check operation or Replace PCB.

1. Repeat the entire balancer calibration.

2. Switch the balancer OFF.

3. Wait a minimum time of 1 minute (approx).

4. Switch the balancer ON and check the proper operation.

5. Replace the PCB board.

1. Replace the PCB board.

1. Check for possible damage or dirt on the encoder disc - clean dirt

with a soft cloth - blow air across the optical units.

2. Check the operation and adjustment of the encoder and in particu-

lar, of the reset signal. (in MACHINE SELF-TEST, Pos counts from 0

to 255 and then 0 again). UP = cw. DOWN = ccw.

3. Replace the main PCB.

1. Press

and respin. Check PHASE in MACHINE SELF-TEST, if

180 deg diff., recalibrate & check piezos..

2. Check encoder adjustment and operation. (clearance .020” to .035”)

3. Check motor operation.

4. Check belt tightness.

5. Check hub nut tightness.

6. Replace the main PCB.

EXIT

START

START

7

EXIT