11 complete boom installation, Complete boom installation -28 – JLG 4017RS Service Manual User Manual

Page 68

Boom

3-28

3614RS, 4017RS

Note: Grease Tilt cylinder barrel end bore and pin before

installing.

12. Remove the plugs from the fittings on the Tilt cylinder

and the caps from the Tilt hoses from the hose carrier.

Install both Tilt hoses (23). Torque as required.

13. If equipped, remove the plugs from the Auxiliary fittings

and the caps from the Auxiliary hoses from the hose

carrier. Install both Auxiliary hoses (24). Torque as

required.

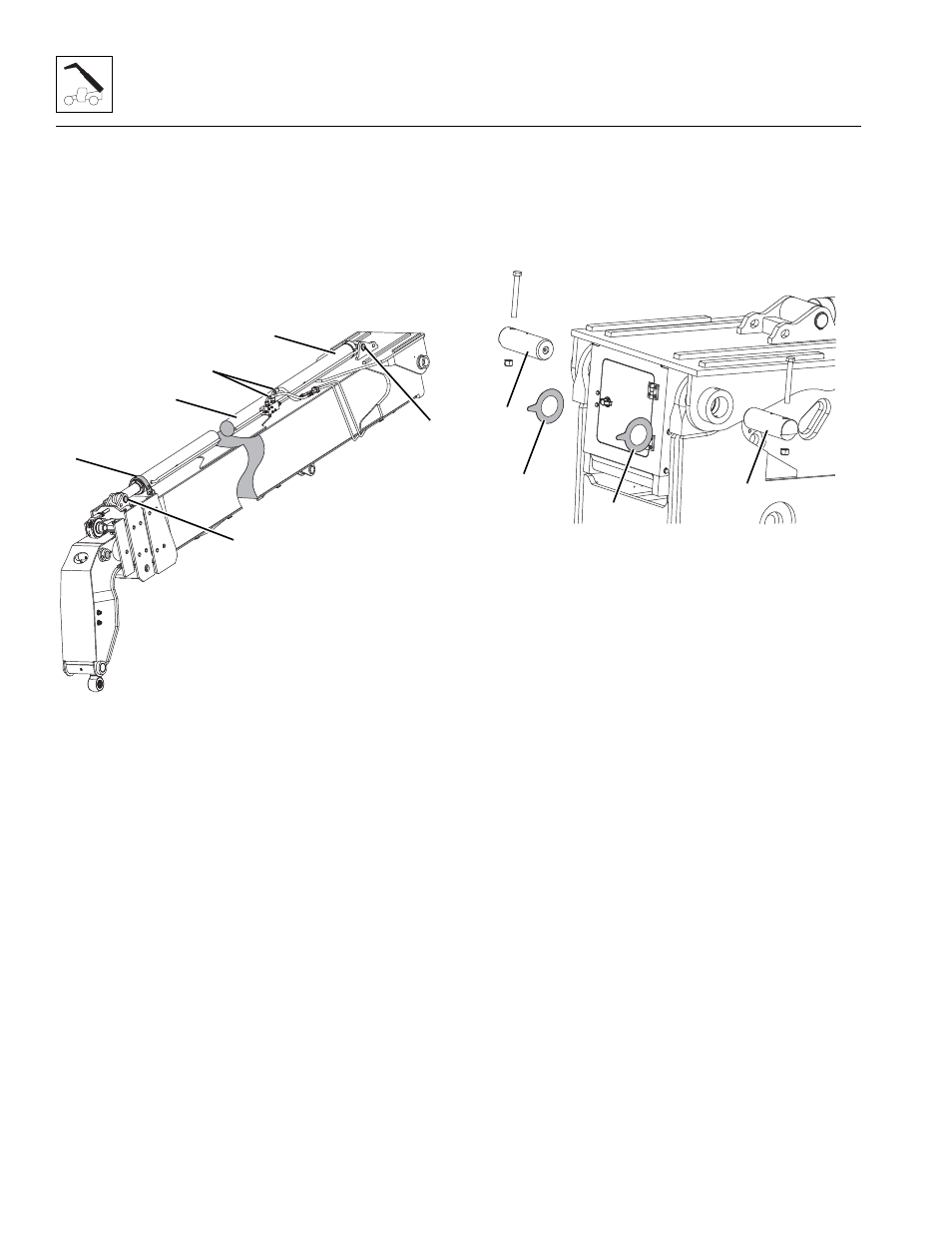

14. Attach a sling around a balance point on the Extend/

Retract cylinder (25) and carefully set on top of the first

boom section.

Note: Grease Extend/Retract cylinder barrel end bore and rod

end bore and pins before installing.

15. Align the Extend/Retract cylinder barrel end (26) with

bore at rear of the first boom section. Install the pin and

retaining clip (27).

16. Align the Extend/Retract cylinder rod end with bore at

front of the second boom section. Install the pin and

retaining clip (28).

17. Install Extend/Retract cylinder support (29). Torque as

required.

18. Uncap and connect the previously labeled extend/

retract cylinder hoses (30) to the extend/retract

cylinder.

Note: Torque extend and retract chains lock/jam nuts to 115-

125Nm (85-92 lb-ft).

3.10.11

Complete Boom Installation

1. Park the machine on a hard, level surface, place the

transmission in (N) NEUTRAL, engage the park brake

and shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel.

3. Using suitable slings, balance the boom assembly, lift

and carefully guide the boom into place. Align the

frame pivot bores with the boom assembly pivot bores.

Install shims, boom pivot pins and lock bolt (31).

4. With the sling still in place, install the compensating

cylinder, pin and lock bolts.

5. With the sling still in place, install the rod end of the lift/

lower cylinder, pin and lock bolt.

Note: Raising the boom up or down with the sling may be

necessary so the boom, compensating and lift/lower cylinder

bores can be aligned for easier pin installation.

6. Uncap and connect the previously labeled extend/

retract cylinder hoses to the extend/retract cylinder.

7. Uncap and connect the previously labeled tilt hoses and

(if equipped) auxiliary hoses to the appropriate cylinder.

8. Install the boom angle sensor arm. Refer to Section

9. Remove slings and/or supports from the boom

assembly.

10. Start the engine and operate all boom functions several

times to bleed any air out of the hydraulic system. Check

for fluid leaks. Check the hydraulic fluid level in the tank

and add fluid as required.

11. Lower the boom assembly and shut engine OFF.

12. Clean up all debris, hydraulic fluid, etc., in, on, near and

around the machine.

MZ7270

27

30

29

28

25

26

M 7590

Z

31

31

31

31