3 after transmission service or replacement, 4 transmission torque converter stall test, 5 torque convertor diaphragm – JLG 4017RS Service Manual User Manual

Page 113: 1 torque convertor diaphragm removal/ installation, 6 troubleshooting, Torque convertor diaphragm, Troubleshooting, After transmission service or replacement, Transmission torque converter stall test, Torque convertor diaphragm removal/installation

6-5

3614RS, 4017RS

Transmission

6.4.3

After Transmission Service or

Replacement

In general:

1. Disconnect and clean all transmission hoses. When

possible, remove transmission lines from machine for

cleaning.

2. Properly clean transmission oil cooler.

3. Install a new hydraulic filter.

4. Check transfer case oil level and add oil as required.

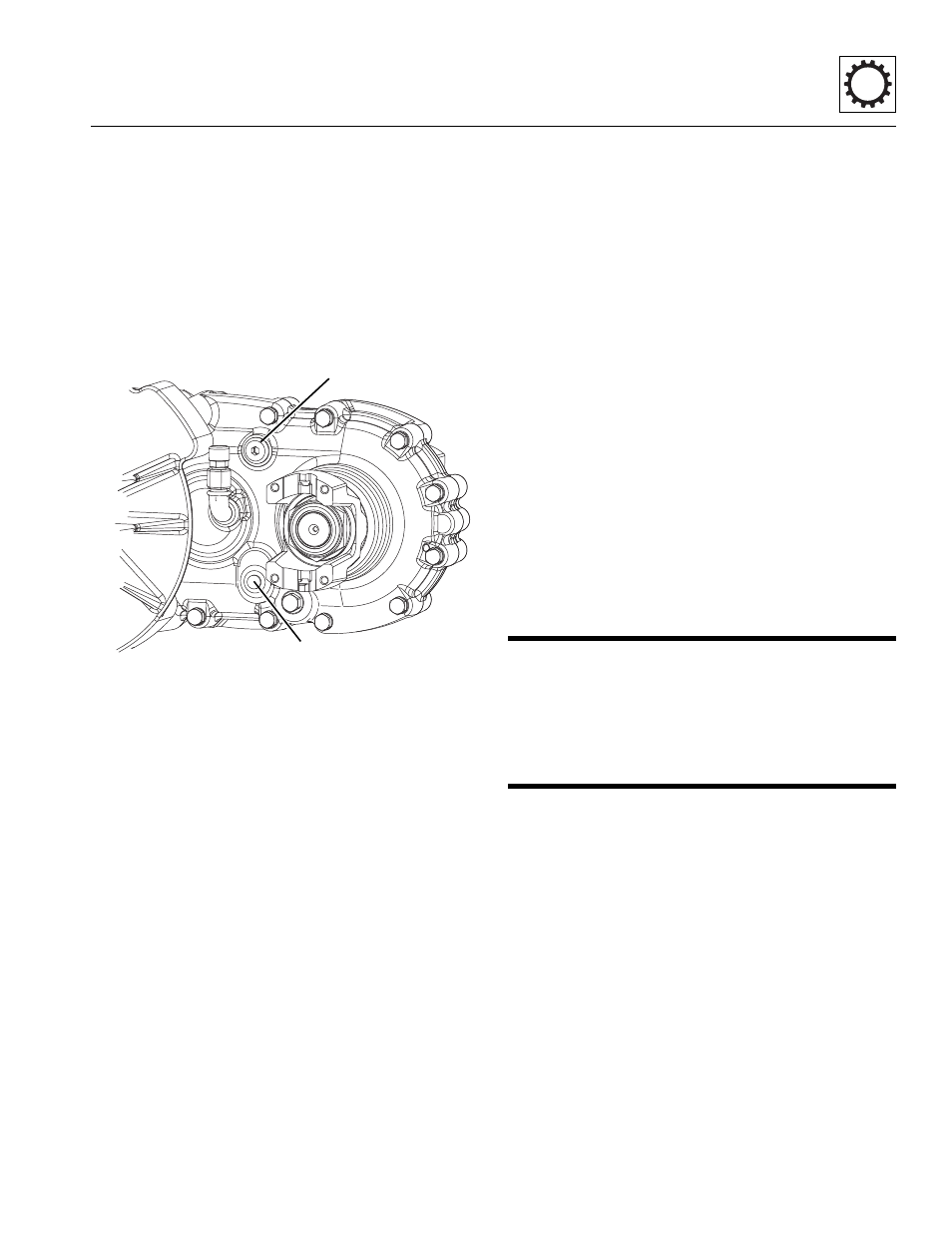

• Transfer Case: Remove transfer case fill plug (7) and

verify oil level at transfer case oil level glass (8). Add oil

as required and torque plug to 34–44 lb-ft (46–60 Nm).

5. Check transmission oil level and add oil as required.

• Transmission: With engine running at low idle and

transmissiom cold, check oil level. Verify oil level is at

“Max” mark on dipstick. Add oil if required.

6. Check torque on drive shaft yoke capscrews.

7. Run engine for two minutes at idle to help prime

transmission oil lines.

8. Recheck level of fluid in hydraulic oil reservoir with

engine running at idle.

9. Add oil as necessary until oil level is visible in upper

gauge window. Recheck oil level when it reaches

operating temperature 83-94° C (180-200° F).

10. Recheck all drain plugs, lines, connections, etc., for leaks,

and tighten where necessary.

6.4.4

Transmission Torque Converter Stall Test

1. Start the machine and bring engine to normal

operating temperature.

Engine - 75° ± 5° C (167° ± 40° F)

Hydraulic Oil - 60° ± 5° C (140° ± 40° F)

Torque Converter - 80° ± 5° C (176° ± 40° F)

2. Ensure that transmission neutralizer switch is in the OFF

position.

3. With engine at high idle and service brake fully

depressed, shift transmission into the highest forward

gear.

4. With transmission in stall condition, torque converter

speed output should be 0 rpm.

5. Record stall speed at a steady state condition after 10

seconds in stall state.

6. Shift the transmission back to neutral after completion

of the test. Allow engine to idle for two minutes to allow

transmission to return to normal operating

temperatures.

7.

Refer to Section 2.4.5, “Transmission Performance

Specifications,” for detailed stall speed information

.

6.5

TORQUE CONVERTOR DIAPHRAGM

6.5.1

Torque Convertor Diaphragm Removal/

Installation

Refer to Section 6.3, “Specifications and Maintenance Information,”

for detailed Torque Convertor Information.

6.6

TROUBLESHOOTING

Refer to Section 6.3, “Specifications and Maintenance

Information,” for detailed Torque Convertor Information.

MZ7170

7

8