10 load moment (85x), 11 hardware (99x), Load moment (85x) – JLG 4017RS Service Manual User Manual

Page 201: Hardware (99x)

9-49

3614RS, 4017RS

Electrical System

9.13.10

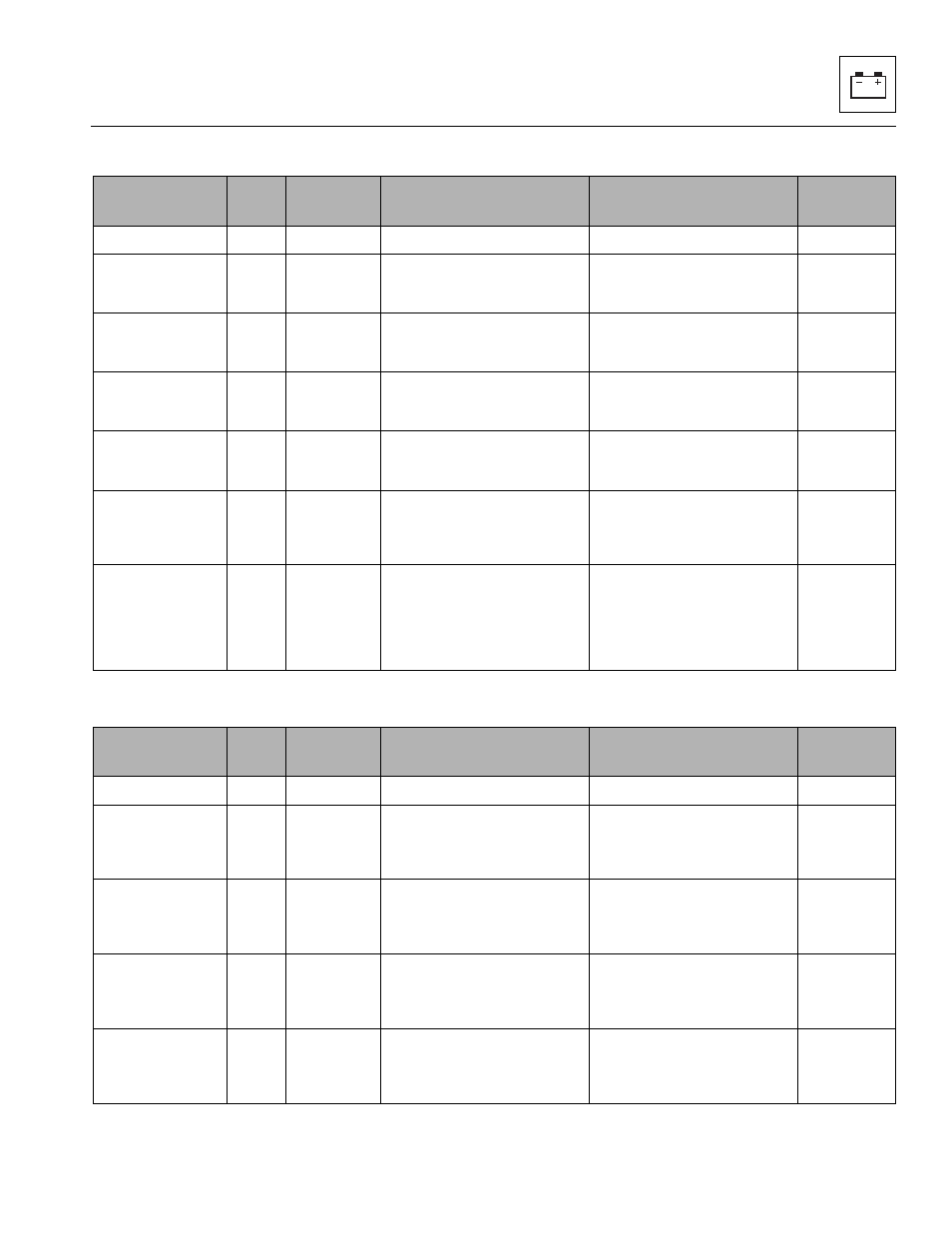

Load Moment (85X)

9.13.11

Hardware (99X)

Message

Fault

Code

Indicators

Other Actions Taken

Trigger for Fault

Latch Until

LOAD MOMENT

85XXX

-

-

-

-

LSI NOT CALIBRATED

8514

5000Ms

Load Moment Cutout assumed to be

100%

Load Monitoring configured;

LSI System reports Fault #6 – System

not calibrated

LSI System

does not

report Fault #6

LSI DETECTED BUT

NOT CONFIGURED

8515

Continuously

Hydraulic functions are prevented

Load Monitoring is not configured;

LSI System messages detected

Load

Monitoring is

configured

LSI LOAD CELL A –

OUT OF RANGE

8516

Continuously

Load Moment Cutout assumed to be

100%

Load Monitoring configured;

LSI System reports Fault #4 – Load

Cell A – Out of Range

Power cycled

LSI LOAD CELL B –

OUT OF RANGE

8517

Continuously

Load Moment Cutout assumed to be

100%

Load Monitoring configured;

LSI System reports Fault #5 – Load

Cell B – Out of Range

Power cycled

LSI CUTOUT OUTPUT

– SHORT TO BATTERY

OR OPEN CIRCUIT

8518

Continuously

Load Moment Cutout assumed to be

100%

Load Monitoring configured;

LSI System reports Fault #7 – Open

or Short Circuit condition on 100%

Cutout digital output

Power cycled

LSI OUT OF

CALIBRATION

8519

5000Ms

Load Moment Cutout assumed to be

100%

Load Monitoring configured;

Verification using OPERATOR TOOLS

à LSI-CAN SYSTEM CHECK indicated

FAIL

(refer to Load Monitoring à

Verification functionality)

Verification or

Calibration

performed

successfully

Message

Fault

Code

Indicators

Other Actions Taken

Trigger for Fault

Latch Until

HARDWARE 99XXX

-

-

-

-

EEPROM FAILURE –

CHECK ALL SETTINGS

998

Continuously

Hydraulic functions are prevented

Engine Start is prevented

ECM Power is de-energized to

shutdown engine

The control system has detected an

EEPROM issue

Power cycled

FUNCTIONS LOCKED

OUT – MACHINE NOT

CONFIGURED

9924

5000Ms

Hydraulic functions are prevented

Engine Start is prevented

ECM Power is de-energized to

shutdown engine

Machine Setup’s MODEL is

UNKNOWN

Machine

Setup’s MODEL

is set; Power

cycled

CURRENT FEEDBACK

GAINS OUT OF RANGE

9944

Continuously

Hydraulic functions are prevented

Engine Start is prevented

Fuel Relay is energized to shutdown

engine

Current feedback calibration data in

the Manufacturing Data Area

(0x4050; J3-1, J3-2, J3-4, J3-5, J3-6,

J3-14) to are not within 204-307

Power cycled

CURRENT FEEDBACK

CALIBRATION

CHECKSUM

INCORRECT

9945

Continuously

Hydraulic functions are prevented

Engine Start is prevented

ECM Power is de-energized to

shutdown engine

Checksum for the current feedback

calibration data in the

Manufacturing Data Area (0x4050)

was improper

Power cycled