5 brake inspection, Brake inspection – JLG 4017RS Service Manual User Manual

Page 99

5-5

3614RS, 4017RS

Axles, Drive Shafts, Wheels and Tires

13. 3614RS Front Axle Only - Connect park brake cable.

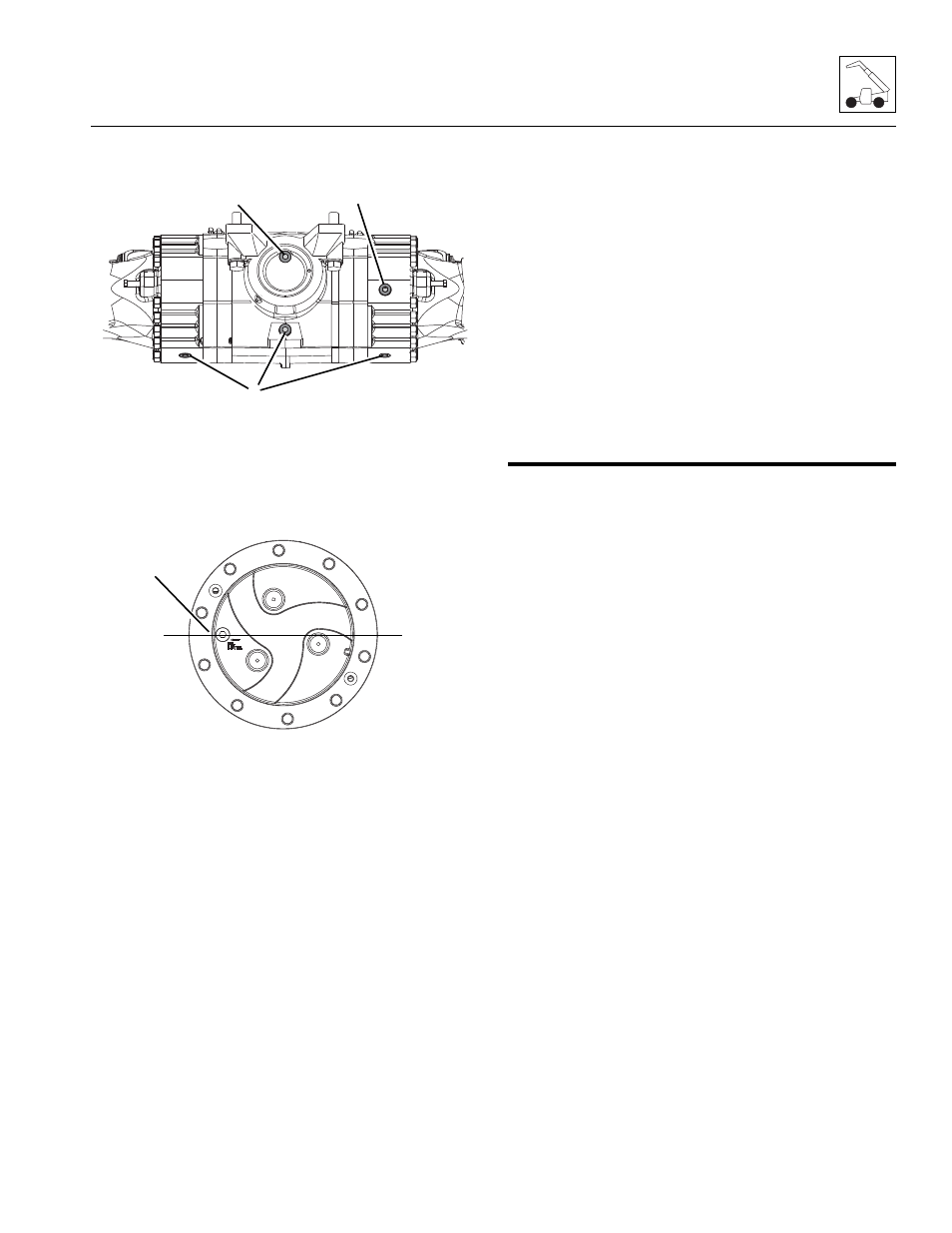

14. Tighten axle oil drain plugs (1), loosen and remove the

axle oil fill plug (3). Loosen and remove check fill plug

(4). Fill until oil level reaches bottom of check fill plug.

Refer to Section 2.5, “Fluids, Lubricants and Capacities,”

for proper oil and capacities.

15. Rotate wheel hubs 90 degrees so wheel hub drain plug

becomes the fill plug (2). Refer to Section 2.5, “Fluids,

Lubricants and Capacities,” for proper oil and capacities.

16. Install the wheel and tire assemblies. Refer to Section

5.10.2, “Installing Wheel and Tire Assembly onto

Machine.”

17. Carefully remove jack, hoist or overhead crane and sling

supporting axle.

18. Carefully raise machine using a suitable jack or hoist.

Remove supports from beneath frame and lower

machine to ground.

19. Remove blocks from front and rear of both tires on

other axle.

Note: ALWAYS use new o-rings when servicing machine.

20. Install new o-rings into fittings. Lubricate o-rings with

clean hydraulic oil.

21. Uncap and connect steering and brake lines at their axle

fittings.

22. Check hydraulic reservoir oil level.

23. Start engine. Turn steering wheel several times

lock to lock, operate frame tilt function several

times in both directions and check function of brakes.

Check for hydraulic leaks, and tighten or repair as

necessary.

24. Install fender assembly. Torque as required.

25. Properly connect battery.

26. Close and secure engine cover.

27. Remove Do Not Operate Tag from ignition key switch

and steering wheel.

Note: Service brake circuit will need to bled after axle

installation. Refer to Section 8.9.3, “Service Brake Bleeding.”

5.5

BRAKE INSPECTION

Detailed axle service instructions are provided in the Axle

Service Manual, refer to Section 5.3, “Axle Specifications and

Maintenance Information.”

M 7620

Z

3

4

1

MT0220

2