Attenzione attention – JLG X23J Operator Manual User Manual

Page 154

BOOM LIFT MODELS X23J

JLG

150

X23JR0620113

7.21 F

IVE

‑

YEARLY INSPECTION

The replacement of the cables and pulleys is advisable every 5 years, even in shorter time

according to the working hours.

Further inspections of the extension system are required in the following situations:

• Machine exposed to extreme environmental conditions (for example low temperatures,

sea environments, etc.).

• Incorrect movement of the arms or noises caused by the movement of the extensions.

• Unused machine for long periods.

• Overloaded machine or subject to collisions.

• Machine subject to short circuit, the ropes could be damaged internally.

Remember that in all cases the Constructor envisions a mandatory check of the entire

machine, including ropes and pulleys, every 1000 hours of use, which must be performed

at a JLG certified assistance centre.

A

FTER HAVING CARRIED OUT ANY MAINTENANCE INTERVENTION

,

BEFORE ALLOWING AN OPERATOR

TO USE THE MACHINE TO ASCEND TO HEIGHT IT S COMPULSORY TO CARRY OUT ALLM ACHINE MOVE

‑

MENTS FROM THE GROUND IN ORDER TO CHECK THE CORRECT FUNCTIONING OF THE HYDRAULIC

AND ELECTRICAL PARTS

. C

HECK THE FUNCTIONING OF ALL SAFETY DEVICESAND THEIR CORRECT

SIGNALLING ON THE MACHINE REMOTE CONTROL

. M

OREOVER

,

AFTER HAVING CARRIED OUT A

SERIES OF MOVEMENTS

,

RE

‑

CONTRL THE BALANCE AND THE DEGREE OF TENSION OF THE ROPES AND

THE EXTENSION OF THE EXTENSIONS

.

ONLY AT THIS POINT IS THE MACHINE READY FOR USE.

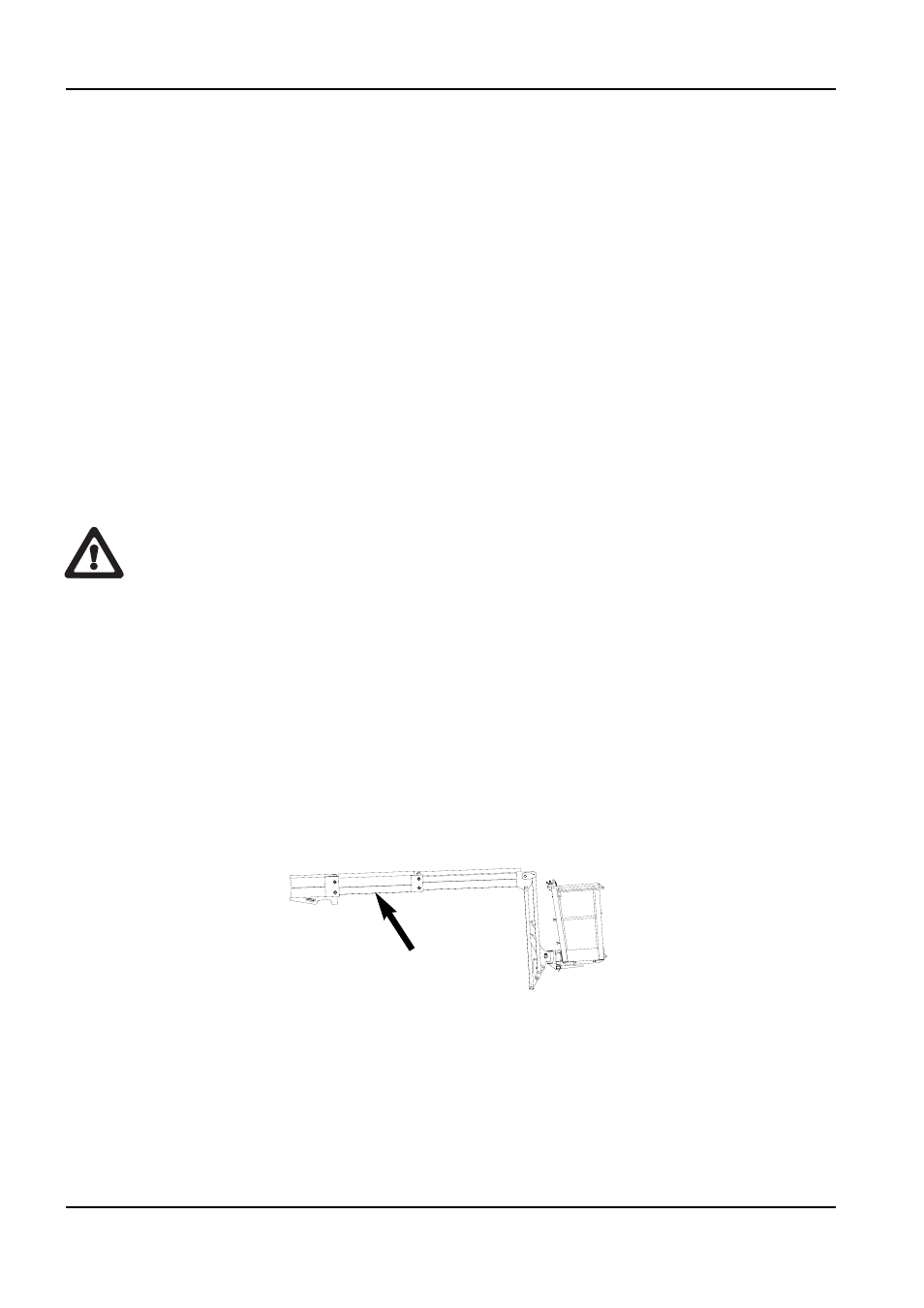

7.22 C

HECKING WEAR OF THE TELESCOPIC ARM SLIDE BLOCKS

‑

Visually check play of the extension arm.

‑

In case the play exceeds 3 mm it is necessary to operate on the plastic registers screwing

them in order to lean to the arm in case of the upper ones, or bringing them to 1 mm

circa in case of the lower ones. Check the support and the correct distance, slipping off

and closing the arm completely.

‑

The slide blocks must be replaced at a JLG authorised workshop.

ATTENZIONE

ATTENTION