JLG X23J Operator Manual User Manual

Page 149

145

BOOM LIFT MODELS X23J

JLG

X23JR0620113

The cartridge must be replaced at every oil change and according to the intervals envisioned

in the maintenance table.

NOTE: it is very important to replace the cartridge for the first time after 50 working hours,

to eliminate pipe and hydraulic compartment work residues from the hydraulic system.

1.

Unscrew cap and remove the filtering cartridge.

2.

If it is very dirty, replace it with a new one having the same features.

3.

Tighten cap A.

7.16 C

HECKING THE PRESENCE AND INTEGRITY OF MACHINE PLATES

‑

Check the presence and legibility of the prohibition, warning, danger and control plates

positioned on the machine.

‑

Consult the paragraph regarding pictograms, to identify any missing or damaged plates.

7.17 C

HECKING THE WORKING PRESSURES OF THE HYDRAULIC SYSTEM

A manometer, with a minimum scale of 250 bar, must be used to carry out this control.

‑

Make sure that the machine is closed and in the rest position.

‑

Make sure that no‑one is present in the machine’s radius of action.

‑

All defined checks must be carried out from the driver’s position in the basket.

a)

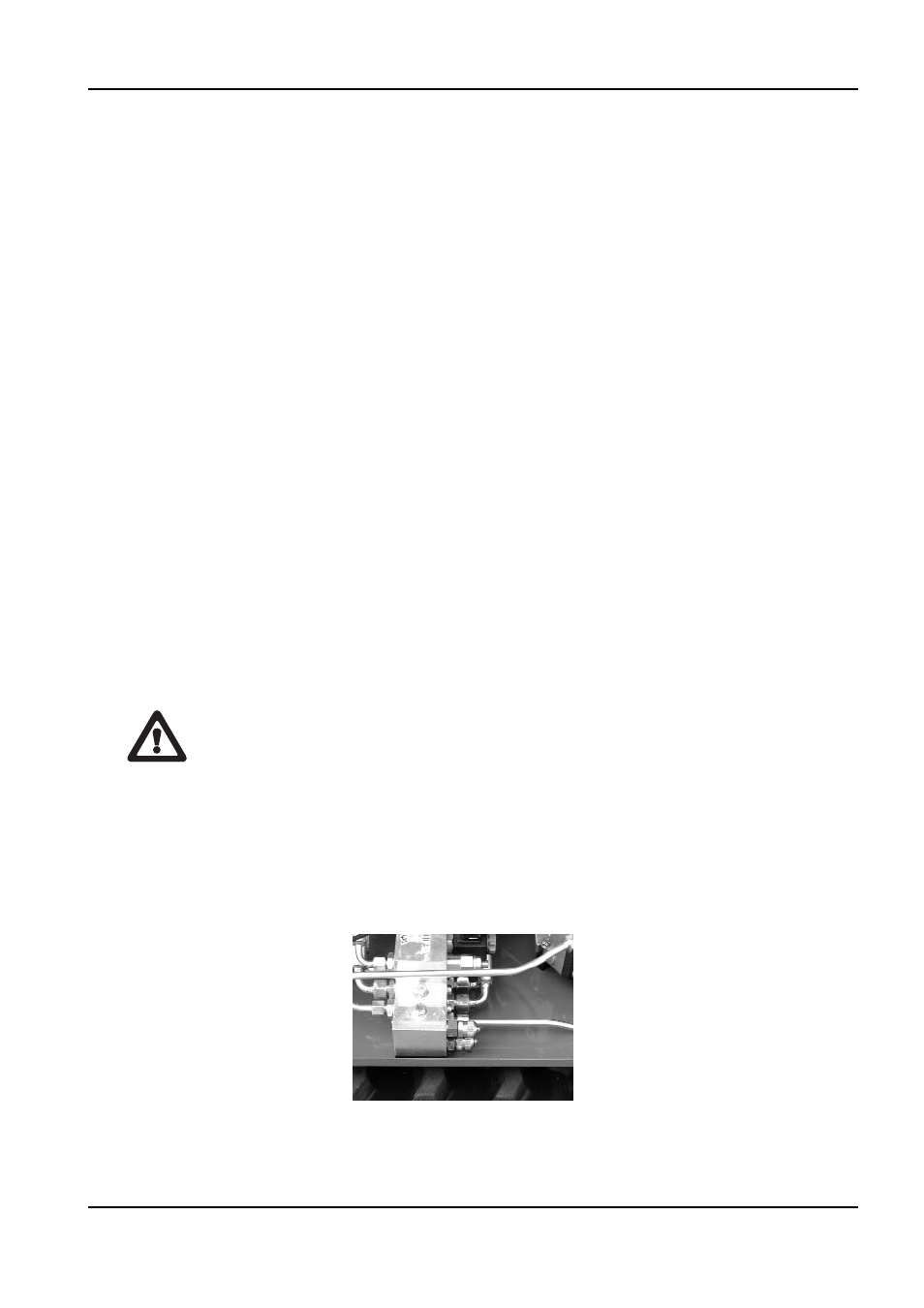

Connect the manometer to the pressure point positioned on the delivery collector alumi‑

nium block, positioned in the proportional valves compartment (see photo).

First connect the MB mouth (ref. Hydraulic system).

b)

Go to the control position and switch the machine on.