Pericolo, Danger – JLG X23J Operator Manual User Manual

Page 140

BOOM LIFT MODELS X23J

JLG

136

X23JR0620113

5. To tighten the track, connect a grease gun to greaser 2 and add grease until belt tension is

within the specified values.

It is not normal if the track remains taught after having turned valve 1 in an anti‑clockwise

direction or if the track is still loose after having put grease into greaser 2. Never try to remo‑

ve the tracks or disassemble the track‑tensioner cylinder because the grease pressure inside

the track is very dangerous.

7.11.3 C

HECKING THE RUBBER TRACKS

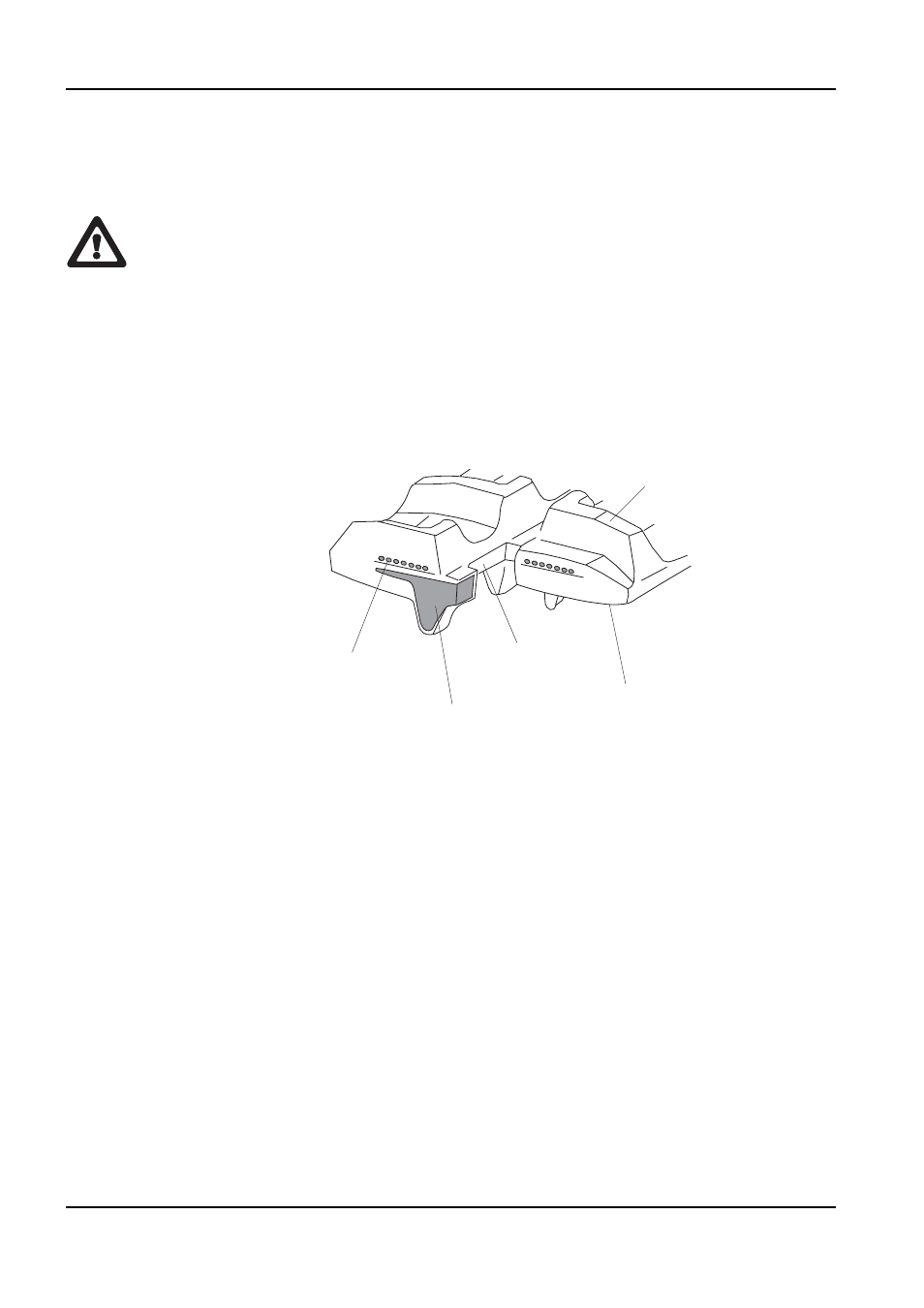

The structure of the rubber track is illustrated in fig.A. The steel ropes and the metal core are

sunk into the rubber. The carved profiles are used to give stability when moving over loose

land. They are situated in the lower part resting on the ground, while the wheel guides situa‑

ted inside the track, prevent the track from escaping from the guide rollers.

Causes of damage

A) Breakage of the steel ropes

Excessive tension causes the steel ropes to break in the following conditions:

‑ when stones or foreign bodies accumulate between the track and the under‑carriage frame;

‑ when the track escapes from its guide;

‑ in the case of strong friction such as rapid direction changes.

B) Wear and breakage of the metal cores

As for breakage of the steel ropes, stated above, excessive tension may cause the metal cores

to bend or break, as may the following causes:

‑ incorrect contact between toothed wheel and track;

‑ breakage of internal rollers;

PERICOLO

Fig. A

CORDE

D'ACCIAIO

SCULTURA

LATO RUOTA

FORO RUOTA

DENTATA

ANIMA METALLICA

CARVED PROFILE

STEEL ROPES

METAL CORE

SPROKET

HOLE

WHEEL SIDE

DANGER