4 second boom section installation, Second boom section installation – JLG G5-18A Service Manual User Manual

Page 38

Boom

3-6

G5-18A, 2505H, 25.5

16. Pull second boom section out of first boom section

approximately 6 in to 8 in (15 cm to 20 cm).

17. Pull tilt hoses and (if equipped) auxiliary hydraulic

hoses through rear of boom.

18. Remove top, side and bottom wear pads from front

of first boom section.

Note: Tag each pad, backing plate, shim and bolts from

each location.

Note: The use of two slings will allow for better stability.

19. Pull second boom section halfway out of first boom

section, reposition sling(s), balancing second boom

section and remove from first boom section.

20. Place second boom section on suitable stands to

begin tear down.

21. Inspect boom and welds. Consult local JLG Dealer if

structural damage is detected.

22. Inspect hoses, hardware, wear pads, mounting

points and other components visible with first boom

section. Replace any item if damaged.

23. Inspect all wear pads for wear. (Refer to Section

3.5.1, “Wear Pad Inspection.”)

3.4.4

Second Boom Section Installation

Note: Lubrication of boom wear surfaces with grease is

recommended to keep boom wear surfaces lubricated

properly. Lubrication of boom wear surfaces is also

recommended when machine is stored, to help

prevent rusting. Refer to Section 2.4, “Fluids, Lubricants

and Capacities.”

1. If previously removed, install extend/retract cylinder

into rear of second boom section. Pin and clip barrel

end of cylinder in place.

2. Install wear pads, shims and bolts to their proper

location at front inside of first boom section.

DO NOT tighten wear pads at this time.

3. Feed the tilt cylinder hoses and if equipped, the

auxiliary hoses through the channel above the

extend/retract cylinder.

4. Using suitable sling(s), balance second boom

section, lift and carefully guide boom into place.

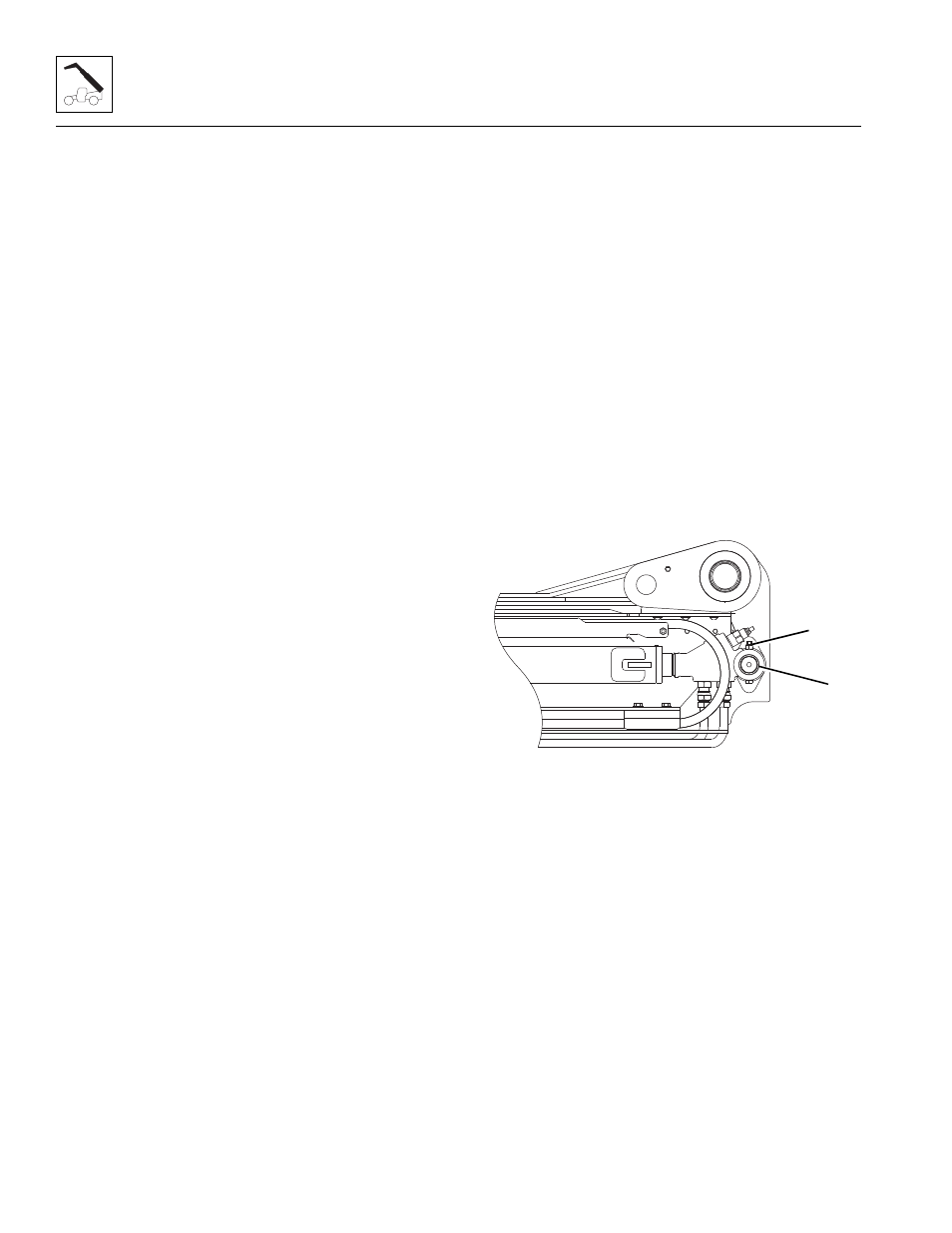

5. Install extend/retract cylinder mounting pin (11).

6. Install lock bolt and nut (10) at rear of

extend/retract cylinder.

7. Install wear pads, shims and bolts previously

removed from rear of second boom section.

DO NOT tighten the wear pads at this time.

8. Uncap and reconnect extend/retract cylinder fittings

and plugs from extend/retract cylinder tubes and

tighten until wrench-tight. Mark fitting, then torque to

specification. Refer to Section 2.2.3, “Hydraulic

Hose Torque Chart.”

9. Uncap and reconnect tilt hoses and (if equipped)

auxiliary hoses. Attach both sets to their appropriate

fittings until wrench-tight. Mark fitting, then torque to

specification. Refer to Section 2.2.3, “Hydraulic

Hose Torque Chart.”

10. Adjust and shim each wear pad as needed.

11. Properly connect battery.

MY1960

11

10