11 variable speed fan valve, Variable speed fan valve – JLG G5-18A Service Manual User Manual

Page 114

Hydraulic System

8-24

G5-18A, 2505H, 25.5

6. Install the solenoid valve and cartridge in the quick

attach valve housing.

c. Quick Attach Installation

1. Attach the quick attach valve to the fittings on the

boom head.

2. Connect the hydraulic hoses, fittings, solenoid wire

terminal leads, etc., to the quick attach.

3. Properly connect the battery.

4. Start the engine and run at approximately 1/3-1/2

throttle for about one minute, without moving the

machine or operating any hydraulic functions.

5. Inspect for leaks and check the level of the hydraulic

fluid in the reservoir. Shut the engine OFF.

Note: Check for leaks and repair as required before

continuing. Add hydraulic fluid to the reservoir as needed.

6. Wipe up any hydraulic fluid spillage in, on, near and

around the machine, work area and tools.

7. Close and secure the battery and engine covers.

8. Remove the Do Not Operate Tags from both the

ignition key and the steering wheel.

d. Quick Attach Valve Test

1. Turn the ignition switch to the ON position, activate

the quick attach switch to switch the auxiliary

position or the quick attach position.

2. If further troubleshooting is required, refer to Section

8.7, “Hydraulic Schematic,” or Section 9.4, “Electrical

System Schematics.”

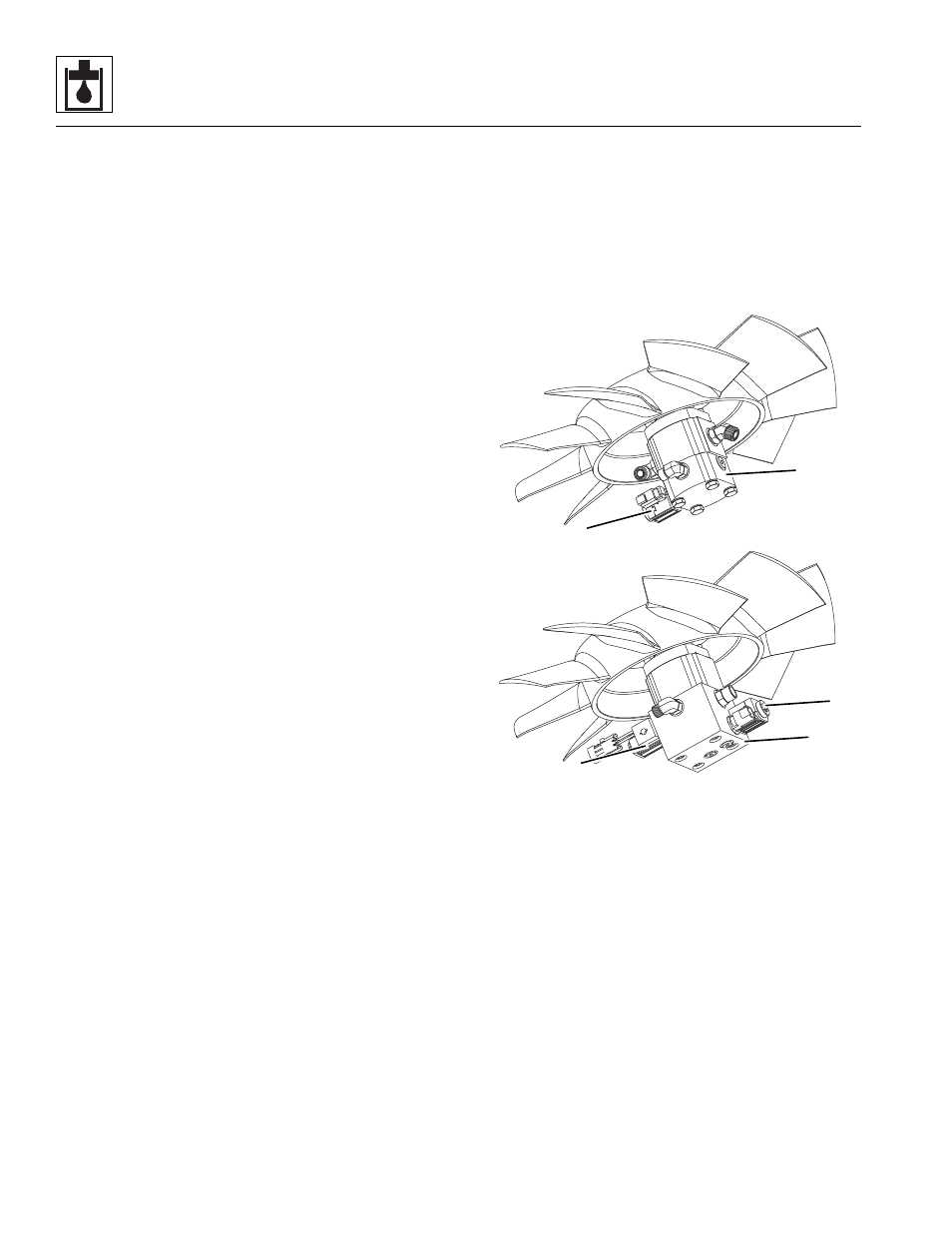

8.11.11

Variable Speed Fan Valve

The variable speed fan valve is located on the bottom

side of the Radiator assembly.

Place a piece of paper over the face of the radiator core.

If the paper is held in place, the fan is rotating in the right

direction.

The housing of the variable fan valve is not serviceable

and must be replaced if defective.

a. Variable Speed Fan Valve Removal

1. Park the machine on a firm, level surface, fully

retract the boom, raise the boom, place the

transmission control lever in (N) NEUTRAL, engage

the park brake and shut the engine OFF.

2. Properly support the boom.

3. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

4. Open the battery and engine covers. Allow the

system fluids to cool.

5. Properly disconnect the battery.

6. Refer to Section 7.2.2, “Radiator/Oil Cooler

Replacement,” for detailed removal instructions.

7. Label or otherwise mark the hydraulic hoses in

relation to the variable speed fan valve (1).

Disconnect and cap all hoses, fittings, solenoid wire

terminal leads, etc.

8. Remove the variable speed fan valve from the

machine. Wipe up any hydraulic fluid spillage in, on,

near and around the machine.

b. Variable Speed Fan Valve Disassembly, Cleaning,

Inspection and Assembly

1. Place the variable speed fan valve assembly on a

suitable work surface.

2. Remove the solenoid valve and cartridge (2) from

the variable speed fan valve housing.

3. Clean all components with a suitable cleaner before

inspection.

MY8680

1

2

VARIABLE SPEED FAN

(if equipped)

VARIABLE SPEED

REVERSING FAN

(if equipped)

1

2

2