2 lsi boom sensors, Lsi boom sensors – JLG G5-18A Service Manual User Manual

Page 147

9-27

G5-18A, 2505H, 25.5

Electrical System

a. LSI Axle Sensor Removal

1. Remove any fork carrier or attachment from the

machine.

2. Park the machine on a firm, level surface, level the

machine, fully retract the boom, fully raise the boom,

place the transmission control lever in (N)

NEUTRAL, engage the park brake and shut the

engine OFF.

3. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

4. Open the battery and engine covers. Allow the

engine to cool.

5. Properly disconnect the battery.

6. Disconnect the LSI electrical connector.

7. Loosen, remove and discard the two bolts holding

the LSI assembly to the rear axle.

8. Remove and discard the sensor assembly.

b. LSI Axle Sensor Installation

1. Ensure threads of both bolt holes are clean and free

from rust, water and debris.

2. Clean the bare metal with a degreasing agent,

Loctite

®

7063™.

3. Remove any excess degreasing agent and allow to

dry.

4. Apply a thin film of Loctite

®

F246™ adhesive to the

flat metal surface of the sensor, ensuring the

adhesive is spread evenly over the entire surface.

Note: Follow all adhesive manufacturer’s

recommendations including storage life.

5. Fit the sensor, ensuring the lead exits in the corner

direction. Secure with two new bolts - Socket HD

Capscrew M10x35x1.5, Grade 12.9.

Note: It is important to prevent distortion of the sensor

element, therefore tighten each bolt finger tight.

Alternately tighten each bolt to 26 lb-ft (35 Nm) and

finally to 52-59 lb-ft (70-80 Nm).

6. Permanently mark position of bolt head and sensor

body.

7. Leave the machine undisturbed for a minimum of 6

hours before moving.

8. Plug the electrical connector into the sensor

assembly.

9. Properly connect the battery.

10. Close and secure the battery and engine covers.

11. Remove the Do Not Operate Tag from the ignition

key switch and the steering wheel.

12. Calibrate the LSI system, refer to Section 9.11.4,

9.11.2

LSI Boom Sensors

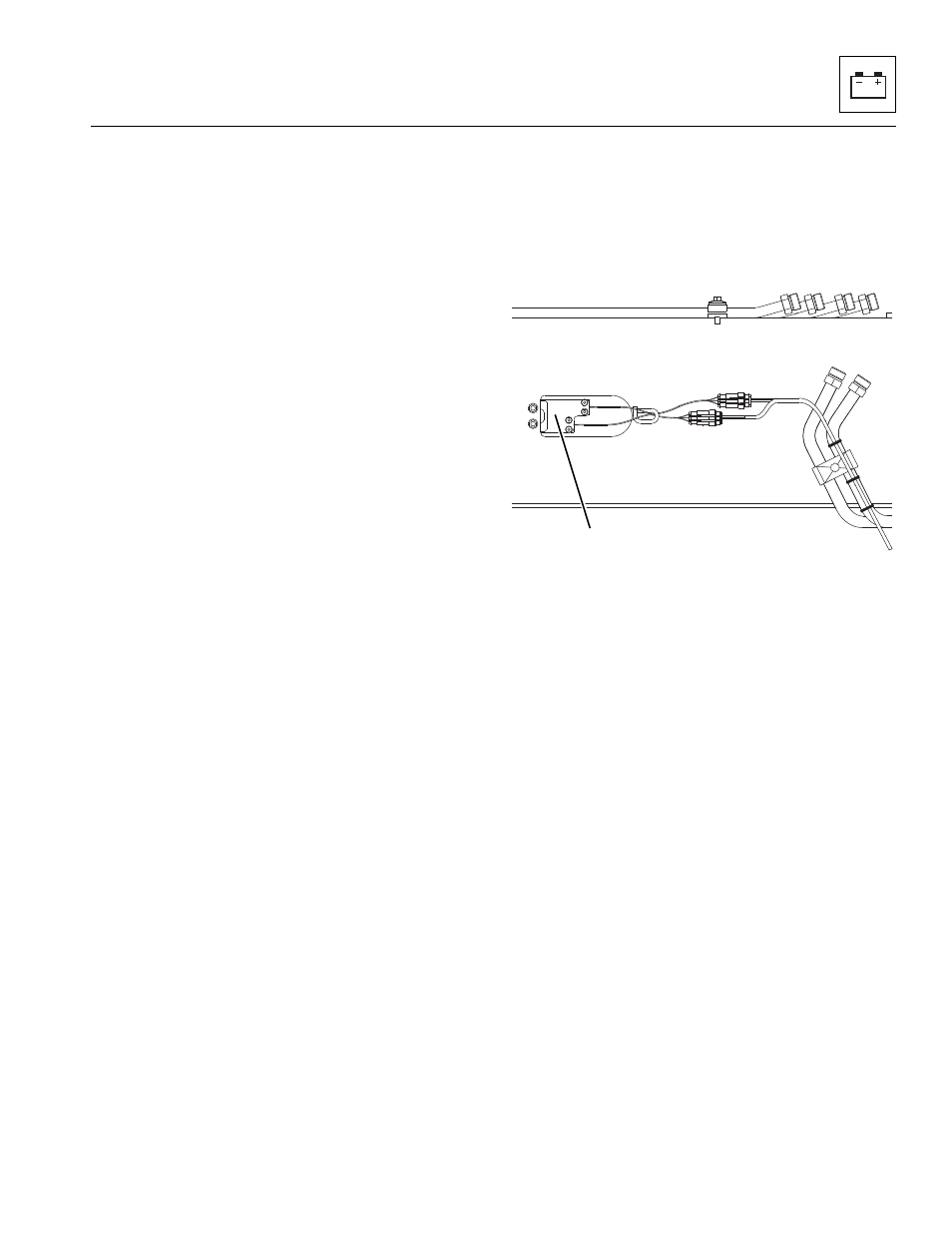

The LSI sensors (2) are bolted on the left inside of the first

boom section.

a. LSI Boom Sensor Removal

1. Remove any fork carrier or attachment from the

machine.

2. Park the machine on a firm, level surface, level the

machine, fully retract the boom, fully raise the boom,

place the transmission control lever in (N)

NEUTRAL, engage the park brake and shut the

engine OFF.

3. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

4. Open the battery and engine covers. Allow the

engine to cool.

5. Properly disconnect the battery.

6. Disconnect the LSI electrical connectors.

7. Loosen and remove the two bolts holding the LSI

assembly to the side of the boom.

8. Remove and discard the sensor assembly.

MAM2910

2