2 safety information, 3 two section boom system, 1 boom system description – JLG G5-18A Service Manual User Manual

Page 35: 4 boom assembly maintenance, 1 complete boom removal, Safety information, Two section boom system, Boom assembly maintenance, Boom system description, Complete boom removal

3-3

G5-18A, 2505H, 25.5

Boom

3.2

SAFETY INFORMATION

3.3

TWO SECTION BOOM SYSTEM

3.3.1

Boom System Description

Boom operates via an interchange among electrical,

hydraulic and mechanical systems. Components

involved include joystick, tilt cylinder, extend/retract

cylinder, lift/lower cylinder, compensating cylinder,

electronic sensors, various pivots, supporting hardware

and other components.

3.4

BOOM ASSEMBLY MAINTENANCE

Boom assembly consists of first and second section

booms and supporting hardware.

Note: Before removing boom or boom section, carriage

or any other attachment must be removed from quick

attach assembly.

Before beginning, conduct a visual inspection of machine

and work area, and review task about to be undertaken.

Read, understand and follow these instructions.

During service of boom, perform following:

1. Check wear pads. (Refer to Section 3.5.1, “Wear

2. Apply grease at all lubrication points (grease fittings).

(Refer to Section 2.6, “Lubrication Schedule.”)

3. Check for proper operation by operating all boom

functions through their full ranges of motion

several times.

Depending on your particular circumstance, the following

procedures explain removal/installation of complete

boom or removal/installation of individual boom sections.

3.4.1

Complete Boom Removal

1. Remove any attachment from quick attach assembly.

2. Park machine on a hard, level surface.

3. Fully retract boom, lower boom, place transmission

control lever in (N) NEUTRAL.

4. Engage park brake and shut engine OFF.

5. Place a Do Not Operate Tag on both ignition key

switch and steering wheel.

6. Allow system fluids to cool.

7. Remove the quick attach assembly. Refer to Section

3.6.1, “Quick Attach Assembly Removal.”

Note: The use of two slings will allow for better stability.

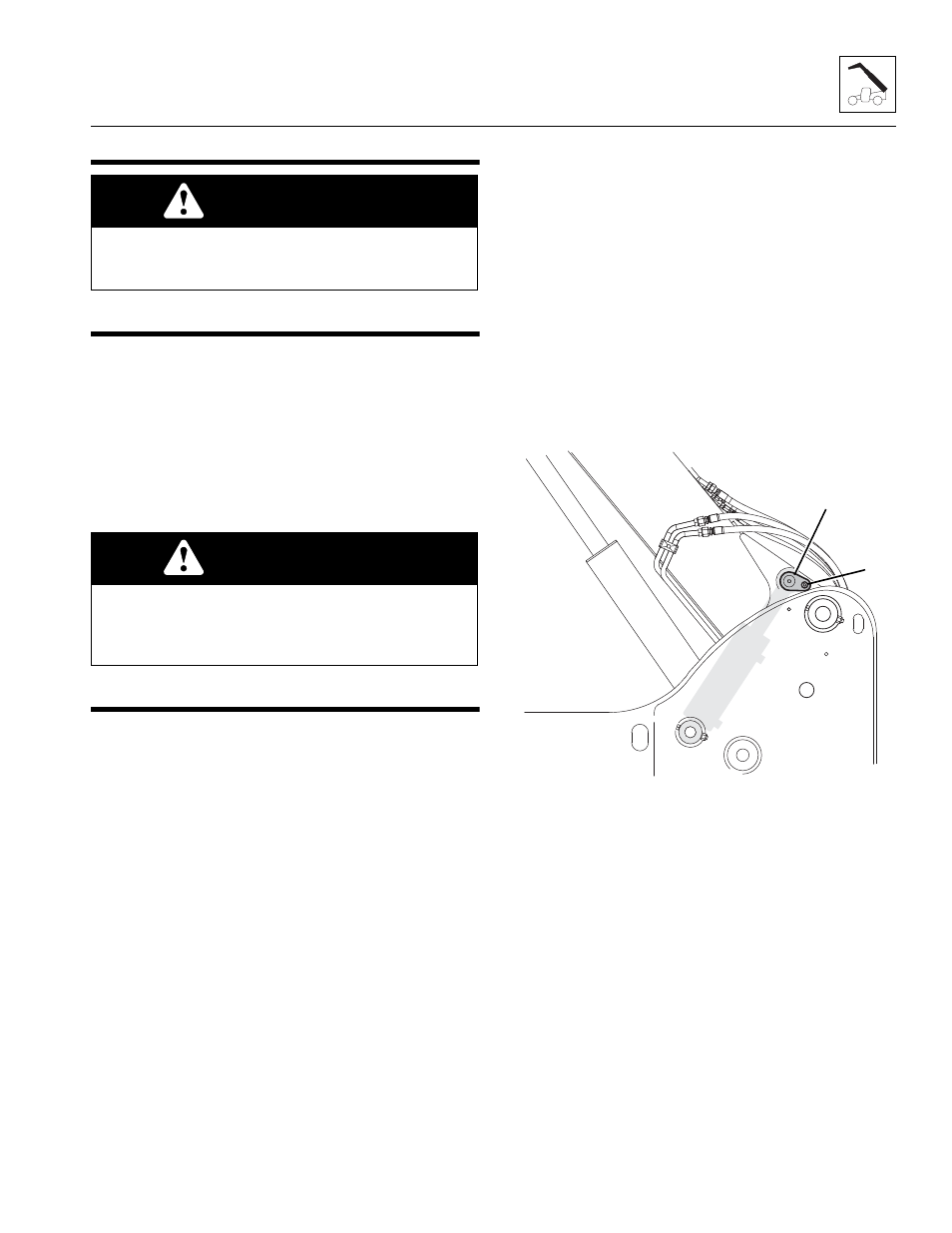

8. Start machine and raise boom to position that will

allow for pin (1) to clear frame for removal.

9. Remove the lock bolt (2) and pin (1) from

compensating cylinder.

WARNING

DO NOT service the machine without following all

safety precautions as outlined in the “Safety Practices”

section of this manual.

WARNING

NEVER weld or drill the boom unless approved in

writing by the manufacturer. The structural integrity of

the boom will be impaired if subjected to any repair

involving welding or drilling.

MY8570

1

2