JLG G5-18A Service Manual User Manual

Page 105

8-15

G5-18A, 2505H, 25.5

Hydraulic System

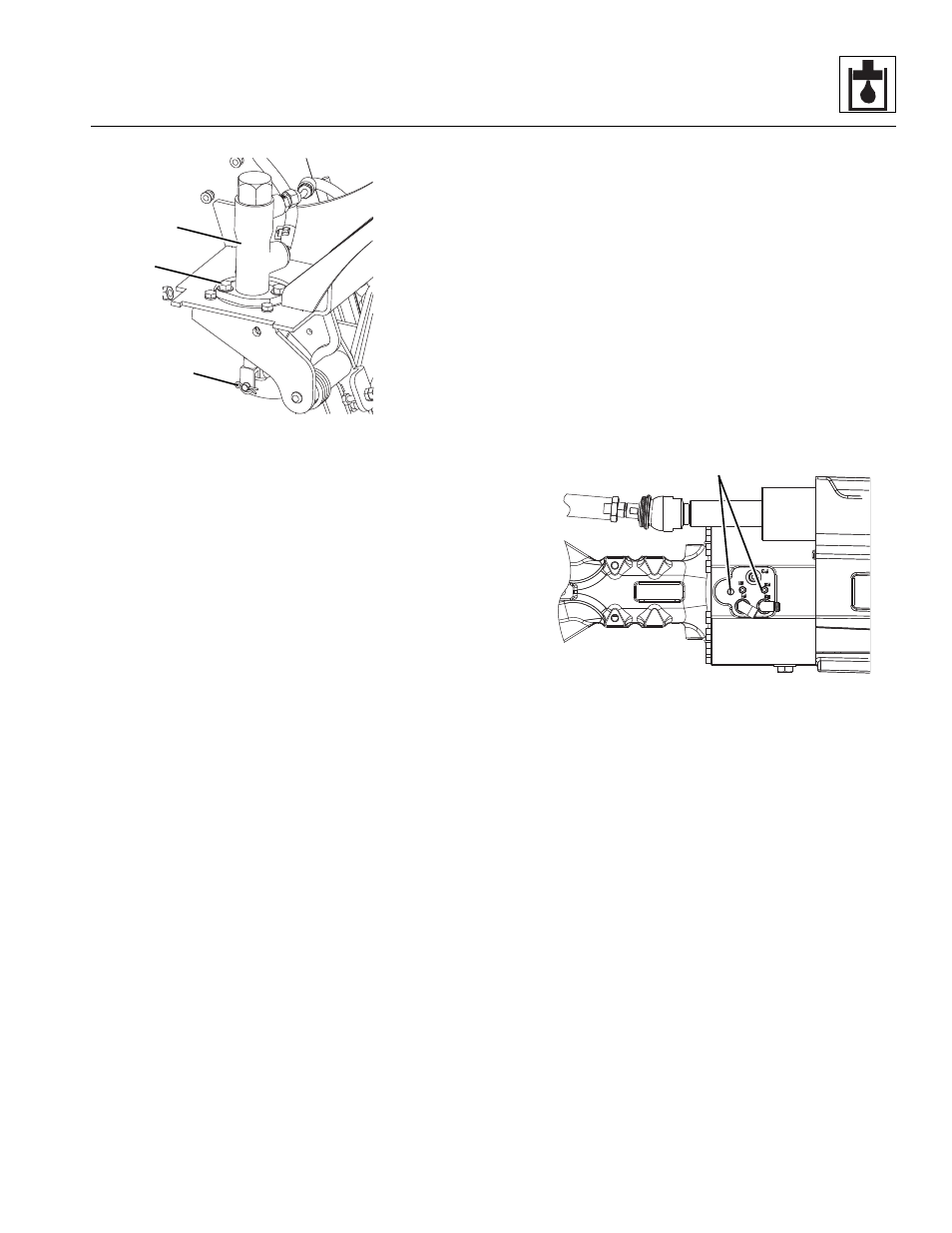

6. Label, disconnect and cap the hydraulic hoses

connected to the service brake valve (1). Cap all

fittings and openings to keep dirt & debris from

entering the brake system.

7. Remove the pin and clip (2) securing the service

brake rod to the brake pedal assembly.

8. Remove the two bolts and washers (3) securing the

service brake valve to the steering column support.

Note: DO NOT disassemble the service brake valve.

The service brake valve is not serviceable and must be

replaced in its entirety, if defective.

b. Service Brake Valve Installation

1. Install the service brake valve to the steering column

support with the previously removed hardware (3).

Torque as required.

Note: ALWAYS replace seals, o-rings, gaskets, etc.,

with new parts to help ensure proper sealing and

operation. Lubricate seals and o-rings with clean

hydraulic oil.

2. Use new oiled o-rings as required. Uncap and

reconnect the previously labeled hydraulic hoses to

the appropriate locations.

3. Install the pin and clip (2) securing the service brake

rod to the brake pedal assembly.

4. Check the routing of all hoses, and tubing for sharp

bends or interference with any rotating members,

and install tie wraps and/or protective conduit as

required. Tighten all tube and hose clamps.

5. Fill the brake reservoir with Mobil 424 10W-30

hydraulic oil.

6. Properly connect the battery.

7. Start the engine and run at approximately one-third

to one-half throttle for about one minute, without

moving the machine or operating any hydraulic

functions.

8. Inspect the service brake valve and connections for

leaks, and check the brake oil level. Shut the engine

OFF.

9. Replace the necessary dash panels.

10. Wipe up any hydraulic oil spillage in, on, near and

around the machine, work area and tools.

11. Close and secure the battery and engine covers.

12. Remove the Do Not Operate Tags from both the

ignition key and the steering wheel.

c. Service Brake Bleeding Procedure

Carefully bleed the brake lines as soon as the brake valve

is installed on the machine. Air in the system will not allow

the brakes to apply properly. There are two brake bleeder

locations (1) on the front axle. The outside bleeder is

used for the park brake circuit. The inside bleeder is used

for the service brake circuit. Work with an assistant to

perform this procedure.

1. Place the transmission control lever in

(N) NEUTRAL, engage the park brake, and start the

engine.Raise the boom to access the brake

bleeders. Support boom and turn off engine.

2. Remove the plastic cap from the brake bleeder.

Attach one end of a length of transparent tubing over

the brake bleeder. Place the other end of this tubing

in a suitable transparent container that is partially

filled with hydraulic oil. The end of the tubing must be

below the oil level in the container.

MY2161

1

2

3

MY2050

1