Jib lift cylinder, Jib lift cylinder -35, Cylinder barrel support -35 – JLG 1850SJ Service Manual User Manual

Page 205: Cylinder length sensor removal -35, Capscrew removal -35

SECTION 5 - BASIC HYDRAULIC INFORMATION & HYDRAULIC SCHEMATICS

3121619

– JLG Lift –

5-35

Jib Lift Cylinder

Refer to Figure 5-65.

DISASSEMBLY

CONTAMINATION MAY DAMAGE EQUIPMENT. DISASSEMBLE CYLINDER ON A

CLEAN WORK SURFACE IN A DIRT FREE WORK AREA.

1.

Connect a suitable auxiliary hydraulic power source to

cylinder port block fitting.

DO NOT FULLY EXTEND CYLINDER TO THE END OF STROKE.

RETRACT CYLINDER SLIGHTLY TO AVOID TRAPPING PRES-

SURE.

2.

Operate hydraulic power source and extend cylinder.

Shut down and disconnect power source. Adequately

support cylinder rod, if applicable.

3.

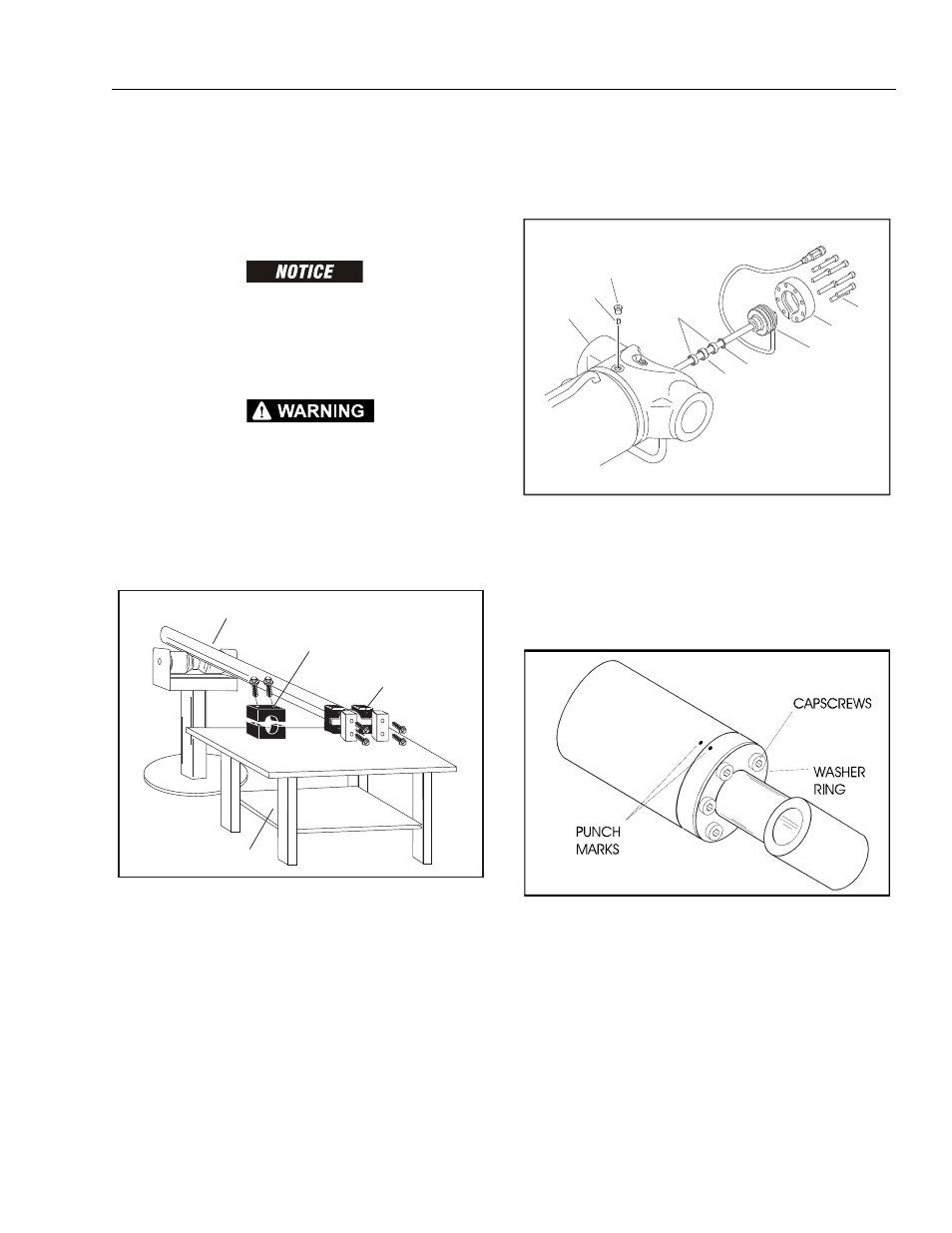

Place cylinder barrel in a suitable holding fixture.

4.

Remove cartridge-type counterbalance valve and fit-

tings from cylinder port block. Discard O-rings.

5.

If necessary, remove eight capscrews (11) and retainer

cap (10). Remove O-Ring plug (5) and setscrew (4).

Remove cylinder length sensor assembly (9) from barrel

(1).

6.

Tap around outside of cylinder head retainer with a suit-

able hammer to break thread-locking compound.

7.

Mark cylinder head and barrel with center punch marks

for later realignment. Remove eight cylinder head cap

screws.

Figure 5-62. Cylinder Barrel Support

1

6

11

9

8

7

10

4

5

Figure 5-63. Cylinder Length Sensor Removal

Figure 5-64. Capscrew Removal