Jib level (slave) cylinder, Jib level (slave) cylinder -17, Cylinder barrel support -17 – JLG 1850SJ Service Manual User Manual

Page 187: Capscrew removal -17, Cylinder rod support -17

SECTION 5 - BASIC HYDRAULIC INFORMATION & HYDRAULIC SCHEMATICS

3121619

– JLG Lift –

5-17

Jib Level (Slave) Cylinder

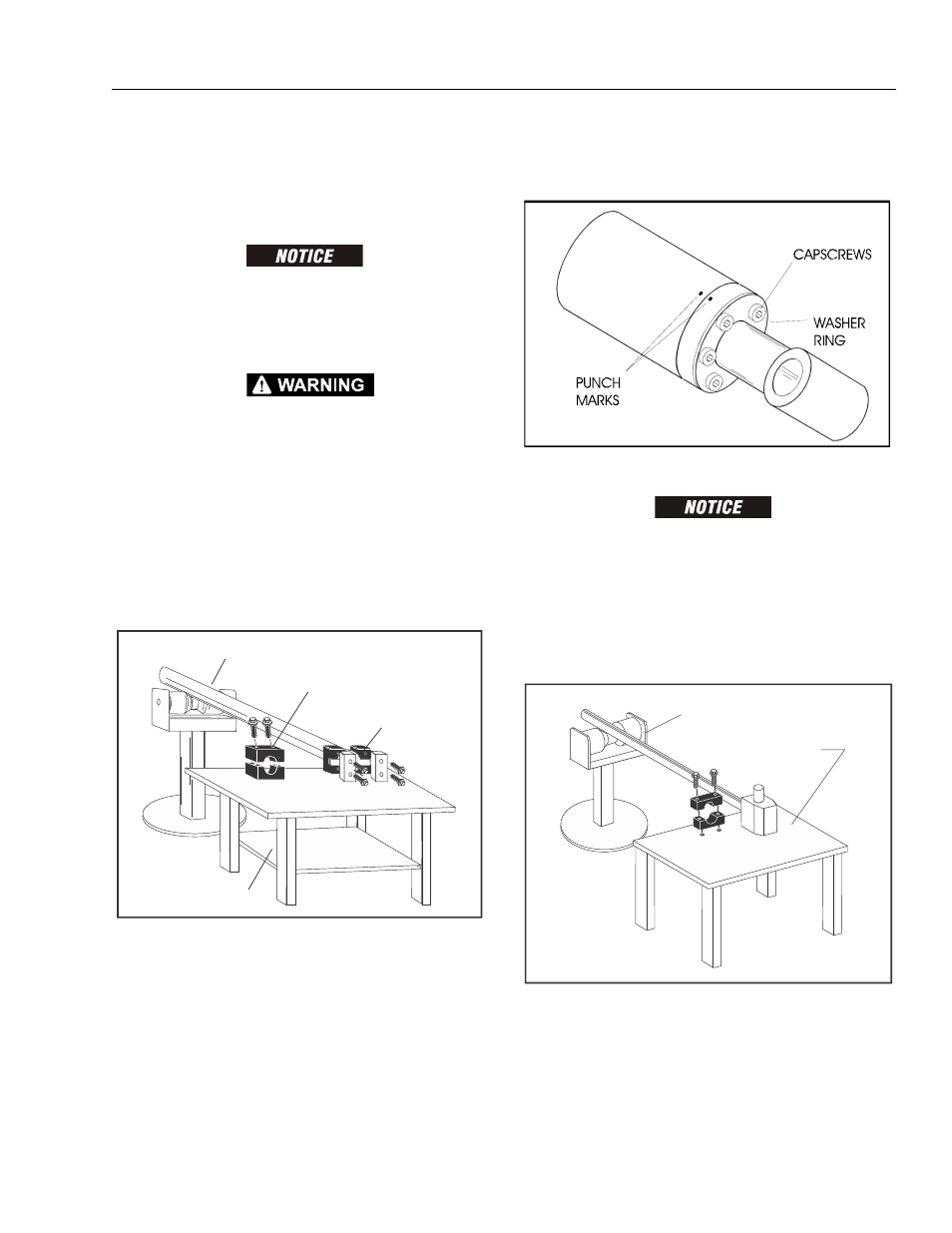

Refer to Figure 5-24.

DISASSEMBLY

CONTAMINATION MAY DAMAGE EQUIPMENT. DISASSEMBLE CYLINDER ON A

CLEAN WORK SURFACE IN A DIRT FREE WORK AREA.

1.

Connect a suitable auxiliary hydraulic power source to

cylinder port block fitting.

DO NOT FULLY EXTEND CYLINDER TO THE END OF STROKE.

RETRACT CYLINDER SLIGHTLY TO AVOID TRAPPING PRES-

SURE.

2.

Operate hydraulic power source and extend cylinder.

Shut down and disconnect power source. Adequately

support cylinder rod.

3.

Remove cartridge-type counterbalance valve and fittings

from cylinder port block. Discard O-rings.

4.

Place cylinder barrel in a suitable holding fixture. Tap

around outside of cylinder head retainer with a suitable

hammer to break thread-locking compound.

5.

Mark cylinder head and barrel with center punch marks

(3) for later realignment. Remove eight cylinder head

capscrews

PULLING ROD OFF-CENTER CAN DAMAGE PISTON AND C YLINDER BARREL

SURFACES. USE EXTREME CARE WHEN REMOVING CYLINDER ROD, HEAD, AND

PISTON.

6.

Clamp barrel securely. Unscrew cylinder head and pull

rod assembly from barrel.

7.

Protect cylinder rod from damage and clamp in a vise or

holding fixture as close to piston as possible.

ROD SUPPORT

PROTECTED ROD CLAMP

BARREL CLAMP

SUPPORT TABLE

Figure 5-21. Cylinder Barrel Support

Figure 5-22. Capscrew Removal

SUPPORT TABLE

ROD SUPPORT

Figure 5-23. Cylinder Rod Support